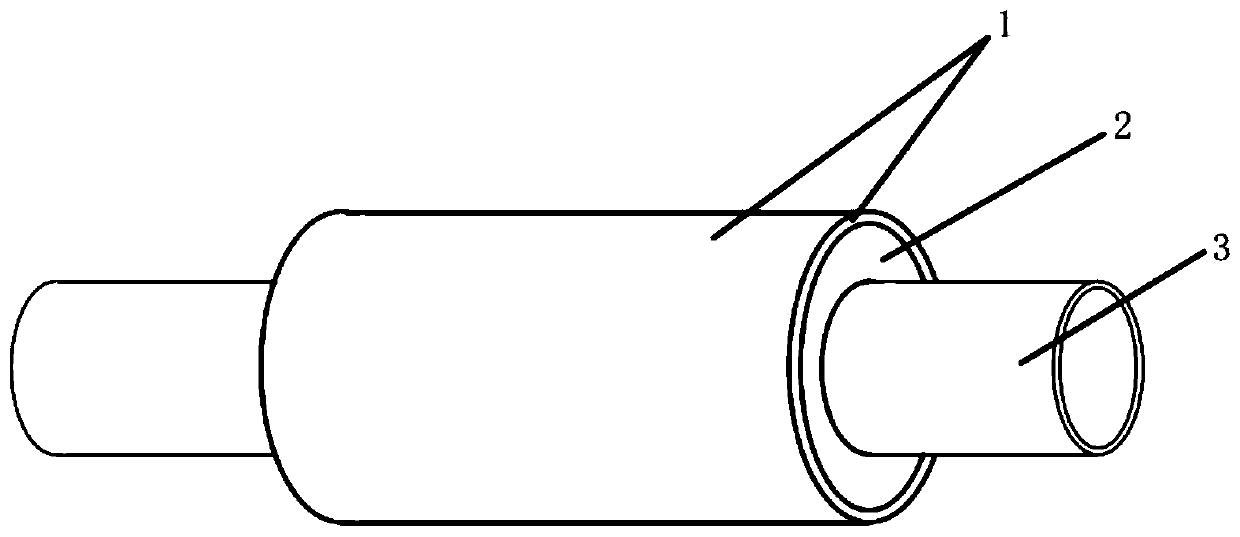

Flexible solid flame-retardant material and cable fireproof flame-retardant sheath with same

A kind of flame retardant material, fire retardant technology, applied in the field of cable fire protection, can solve the problems of insufficient fire retardant coating, too much fire retardant coating, complicated cable lines, etc., to reduce the burning range and the foaming duration is long , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Elastic emulsion: 18%; Catalyst: 20%; Charging agent: 15%; Foaming agent: 15%; Inorganic pigment and filler: 1.5%; Water: 10%; Silicone waterproofing agent: 2%; ; High viscosity clay powder: 11%; Curing agent: 5%;

Embodiment 2

[0050] Elastic emulsion: 20%; Catalyst: 18%; Charging agent: 16%; Foaming agent: 15%; Inorganic pigment and filler: 1%; Water: 10%; Silicone waterproofing agent: 2%; ; High viscosity clay powder: 13%; Curing agent: 3%;

Embodiment 3

[0052] Elastic emulsion: 15%; Catalyst: 20%; Charging agent: 18%; Foaming agent: 18%; Inorganic pigment and filler: 1%; Water: 10%; Silicone waterproofing agent: 3%; Talc powder: 1% ; High viscosity clay powder: 10%; Curing agent: 4%;

[0053] The preparation method of the flexible solid flame-retardant material described in Examples 1-3 is as follows:

[0054](1) Add the elastic emulsion, char-forming agent, foaming agent, high-viscosity clay powder and 50% water into the mixer for stirring according to the above weight parts, the temperature is controlled at 100-110°C, and the stirring speed is 500 rpm- 800 rpm, stirring time is 3-5 minutes, then add catalyst, inorganic pigments and fillers, silicone waterproofing agent, talcum powder, and the remaining 50% water, increase the stirring speed to 1000-1200 rpm, first stir for 3 After -5 minutes, lower the temperature to 30-50°C while stirring, and reduce the stirring speed to 500-800 rpm until it becomes a sticky uniform slur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com