Method for supplying heat in converter by using carbon-based heating agent

A technology for supplementing heat and heating agents, which is applied in the field of iron and steel metallurgy, and can solve the problems of low purity of molten steel, large price differences in stages, and high consumption of power consumption electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] 1. The carbon-based heating agent used in this example was purchased from Jiangsu Jianai High Temperature Material Co., Ltd., and the product number is 644103.

[0012] Requirements for the manufacture of carbon-based heating agents for manufacturers:

[0013] Physical properties: It is made into briquettes, which can be put into the furnace directly in the high-level silo. It is not suitable for crushing, and there is little pulverization after adding.

[0014] Physical and chemical indicators: carbon content ≥ 75%, sulfur content ≤ 0.2%, moisture ≤ 2%.

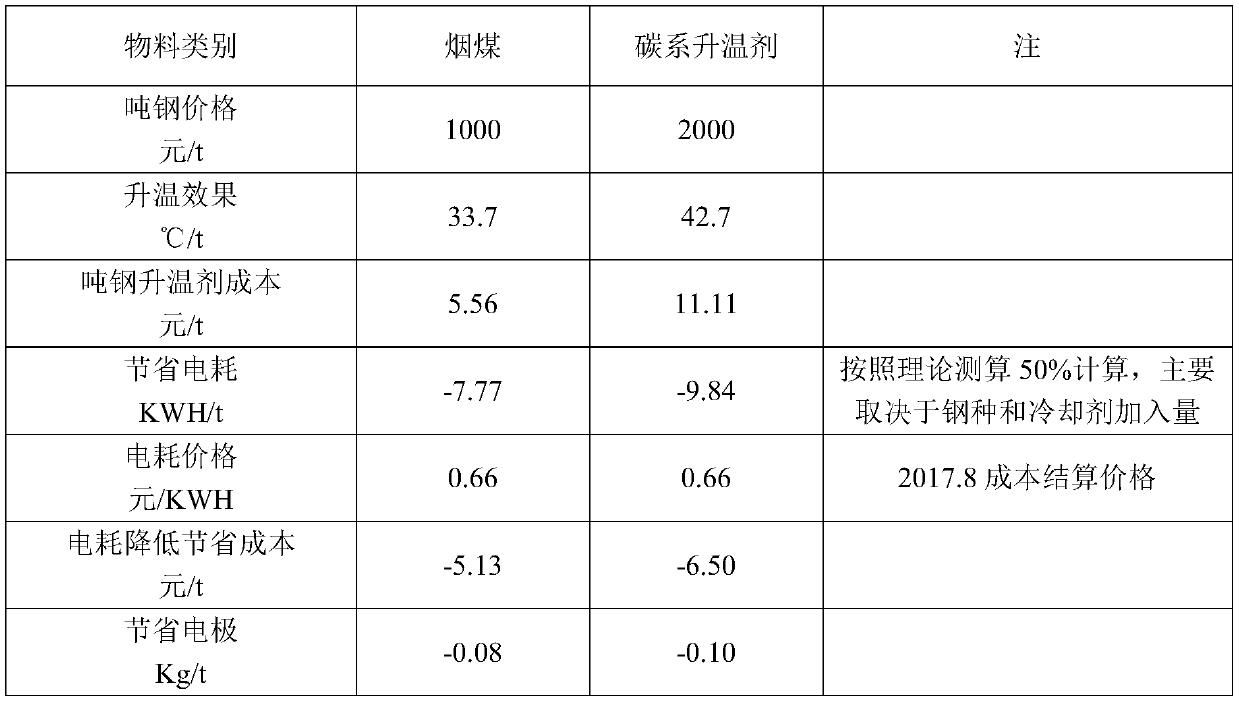

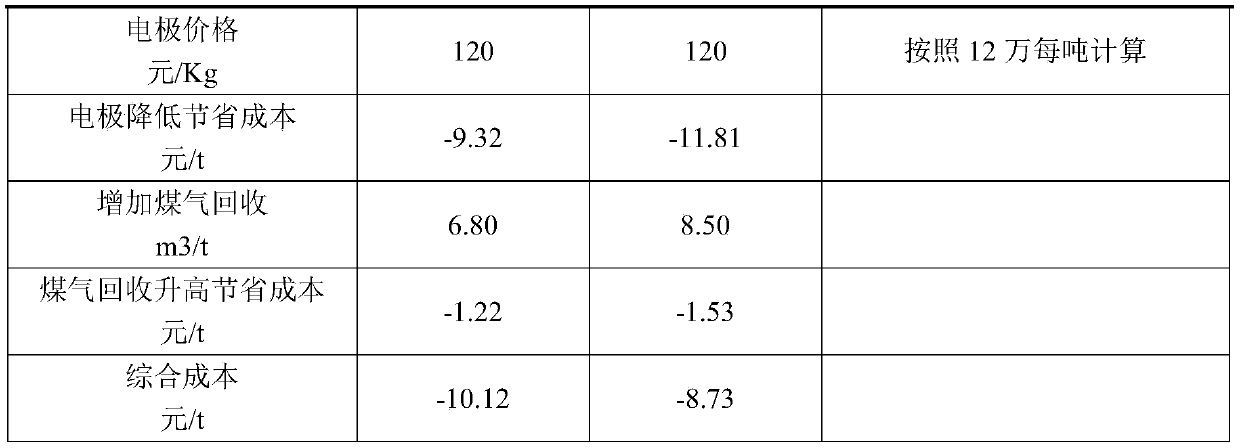

[0015] 2. Comparing the use effect of carbon-based heating agent and anthracite, it is finally decided to use carbon-based heating agent.

[0016] (1) Composition comparison

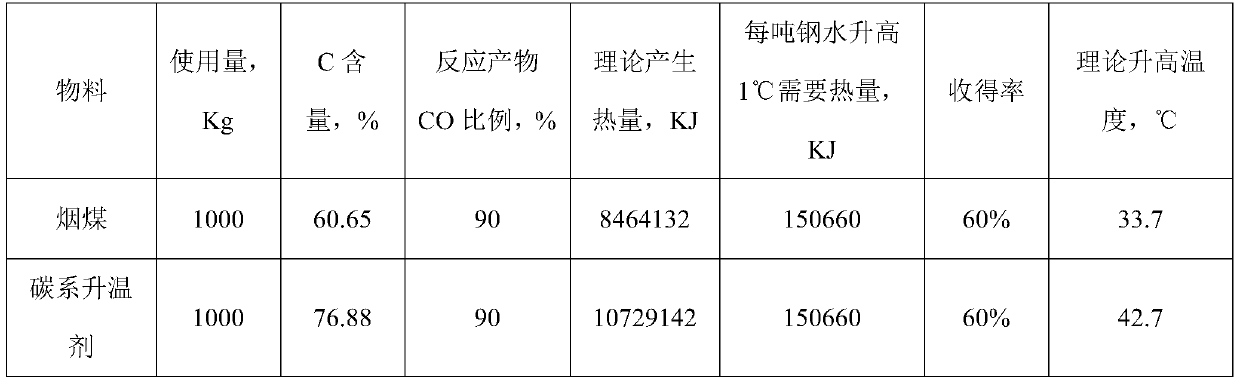

[0017] The composition comparison of bituminous coal and carbon-based heating agent is as follows:

[0018] Material name C / % S / % N / % Volatile matter / % Ash / % bituminous coal 60.65 0.55 - 33.84 5.51 Carbon based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com