High-parameter ORC turbine power generation equipment applied to engine waste heat recovery and ORC device

A technology for power generation equipment and waste heat recovery. It is used in mechanical equipment, steam engine devices, engine components, etc. It can solve the problems of difficult design and manufacturing, large pressure ratio, and low flow rate, and achieve small and compact design structure, high expansion efficiency, and shaft. The effect of short tie length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

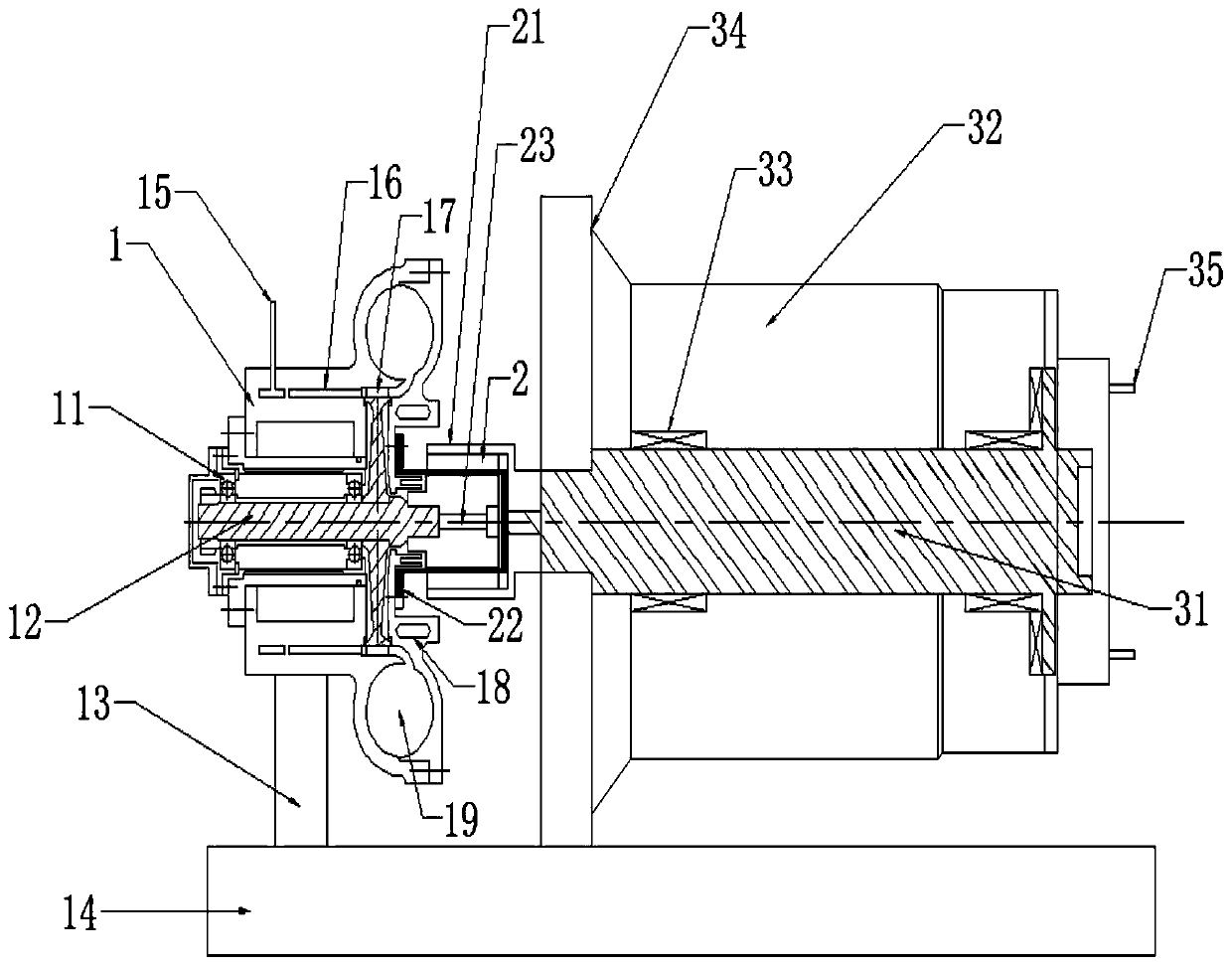

[0037] see Figure 4 , an ORC device, including an ORC working medium circulation system, an engine exhaust system, a power generation system, a boosted air system and an external cooling water system, wherein the power generation system adopts the above-mentioned turbine power generation equipment.

[0038] Using high-temperature waste heat of exhaust gas for direct heating, choosing a suitable working fluid is one of the difficulties of high-parameter ORC. The refrigerants mentioned in existing patents, such as R245fa and R134a, are used at a lower temperature, not exceeding 15°C, otherwise they will decompose and decompose at high temperatures. Hydrogen fluoride HF is highly corrosive, highly volatile, and toxic to humans and the environment. This type of working fluid has a greenhouse effect and has a destructive effect on ozone, and the refrigerant is relatively expensive. In the selection of ORC cycle working fluid, the applicant has considered alcohols after many deriv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com