Hafnium corrosion plate type monitoring sample and preparation method thereof

A plate type and ingot casting technology, applied in the field of hafnium processing, can solve the problems of large deviation of chemical composition, low production efficiency, inability to achieve uniformity, etc., and achieve the effect of small deviation in size, improvement of consistency, and control of grain size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

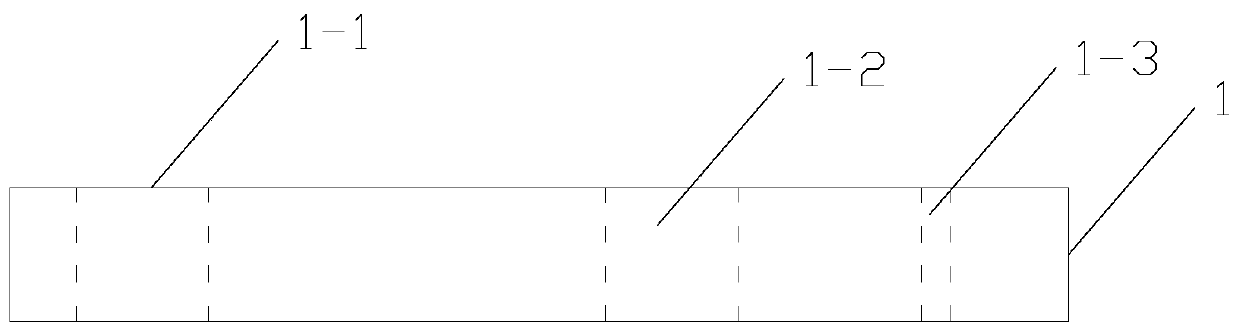

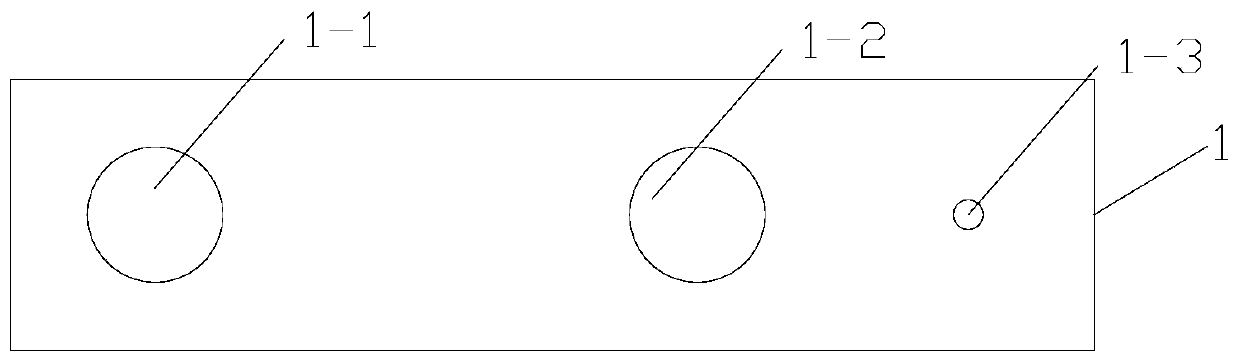

[0048] The thickness of the hafnium corrosion plate type monitoring sample in this embodiment is 3.01mm, the width is 19.95mm, the length is 30.05mm, the aperture is 2.2mm, the grain size level is ≥10, and the grain size level is in accordance with "GB / T6394 Metal Average Grain Particle Size Determination Method" to determine;

[0049]The mass percentage of zirconium in the hafnium corrosion plate type monitoring sample is 0.10% to 0.12%, the mass percentage of nitrogen is 0.001% to 0.002%, the mass percentage of hydrogen is 0.003% to 0.004%, and the mass percentage of oxygen is 0.003% to 0.004%. The mass percentage is 0.002%-0.004%.

[0050] The preparation method of the hafnium corrosion plate type monitoring sample of the present embodiment comprises the following steps:

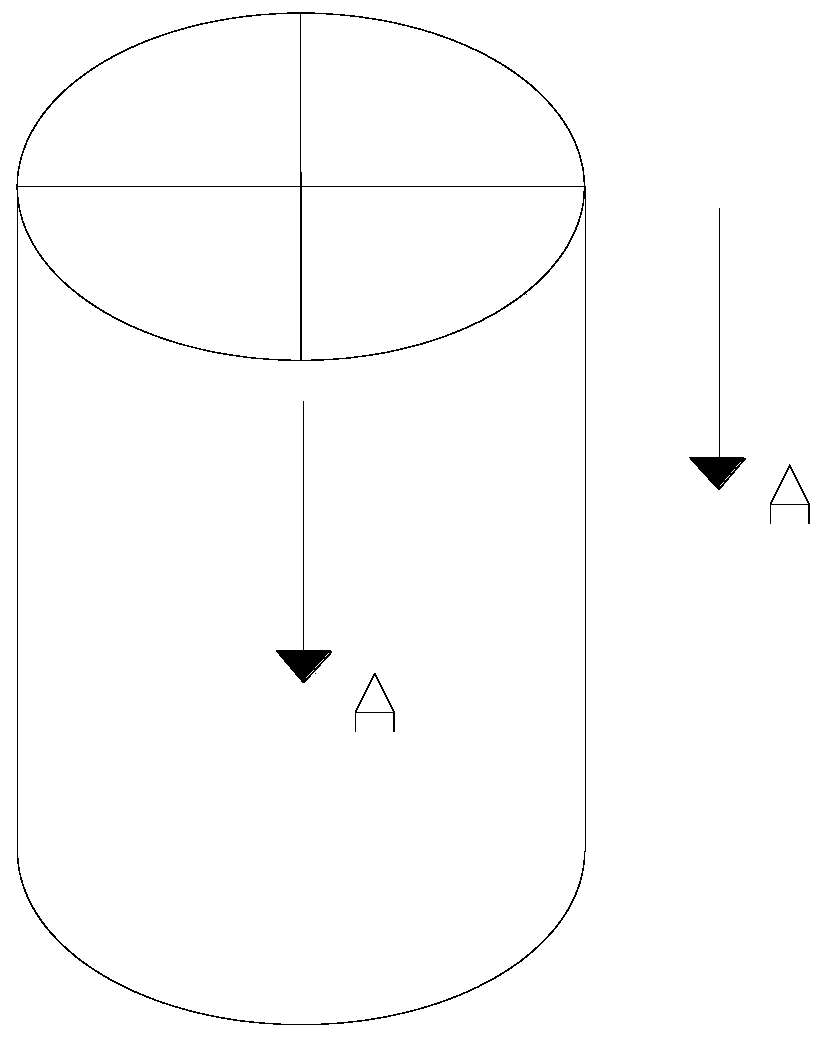

[0051] Step 1. Processing a plurality of hafnium crystal bars with a diameter of 25 mm to 35 mm into hafnium electrodes with a cross-sectional diameter smaller than the diameter of the crucible; the spec...

Embodiment 2

[0066] The thickness of the hafnium corrosion plate type monitoring sample in this embodiment is 3.00mm, the width is 19.9mm, the length is 29.9mm, the aperture is 2.2mm, the grain size level is ≥10, and the grain size level is in accordance with "GB / T6394 Metal Average Grain Particle Size Determination Method" to determine;

[0067] The mass percentage of zirconium in the hafnium corrosion plate type monitoring sample is 0.13% to 0.15%, the mass percentage of nitrogen is 0.001% to 0.002%, the mass percentage of hydrogen is 0.004% to 0.005%, and the mass percentage of oxygen is 0.004% to 0.005%. The mass percentage is 0.004%-0.006%.

[0068] The preparation method of the hafnium corrosion plate type monitoring sample of the present embodiment comprises the following steps:

[0069] Step 1. Processing a plurality of hafnium crystal bars with a diameter of 25 mm to 35 mm into hafnium electrodes with a cross-sectional diameter smaller than the diameter of the crucible; the speci...

Embodiment 3

[0084] The thickness of the hafnium corrosion plate type monitoring sample in this embodiment is 3.05mm, the width is 20.1mm, the length is 30.1mm, the aperture is 2.2mm, the grain size level is ≥10, and the grain size level is in accordance with "GB / T6394 Metal Average Grain Particle Size Determination Method" to determine;

[0085] The mass percentage of zirconium in the hafnium corrosion plate type monitoring sample is 0.12% to 0.13%, the mass percentage of nitrogen is 0.001% to 0.002%, the mass percentage of hydrogen is 0.003% to 0.004%, and the mass percentage of oxygen is 0.003% to 0.004%. The mass percentage is 0.006%-0.009%.

[0086] The preparation method of the hafnium corrosion plate type monitoring sample of the present embodiment comprises the following steps:

[0087] Step 1. Processing a plurality of hafnium crystal bars with a diameter of 25 mm to 35 mm into hafnium electrodes with a cross-sectional diameter smaller than the diameter of the crucible; the speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com