Transition metal/nitrogen-doped porous carbon nanosphere electrocatalyst and preparation method thereof

A nitrogen-doped porous carbon and transition metal technology, which can be used in fuel cell type half cells and primary cell type half cells, circuits, electrical components, etc. The nitrogen process is complex and other problems, to achieve the effect of improving catalytic activity, improving catalytic efficiency, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

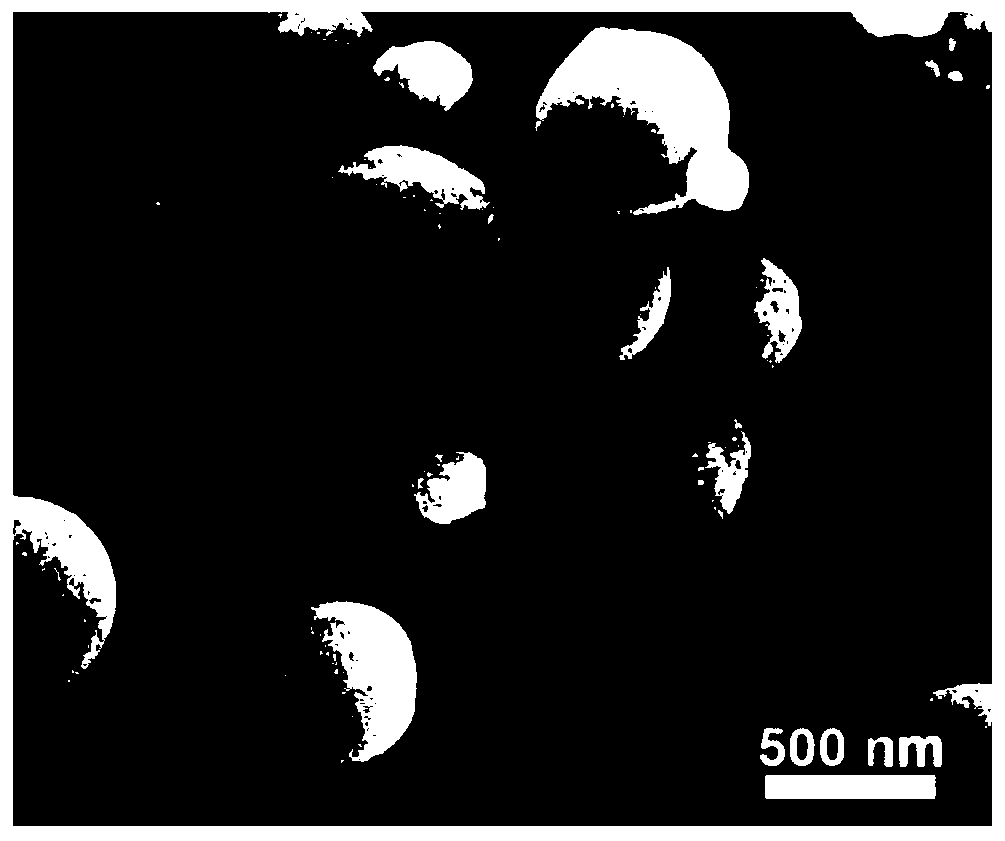

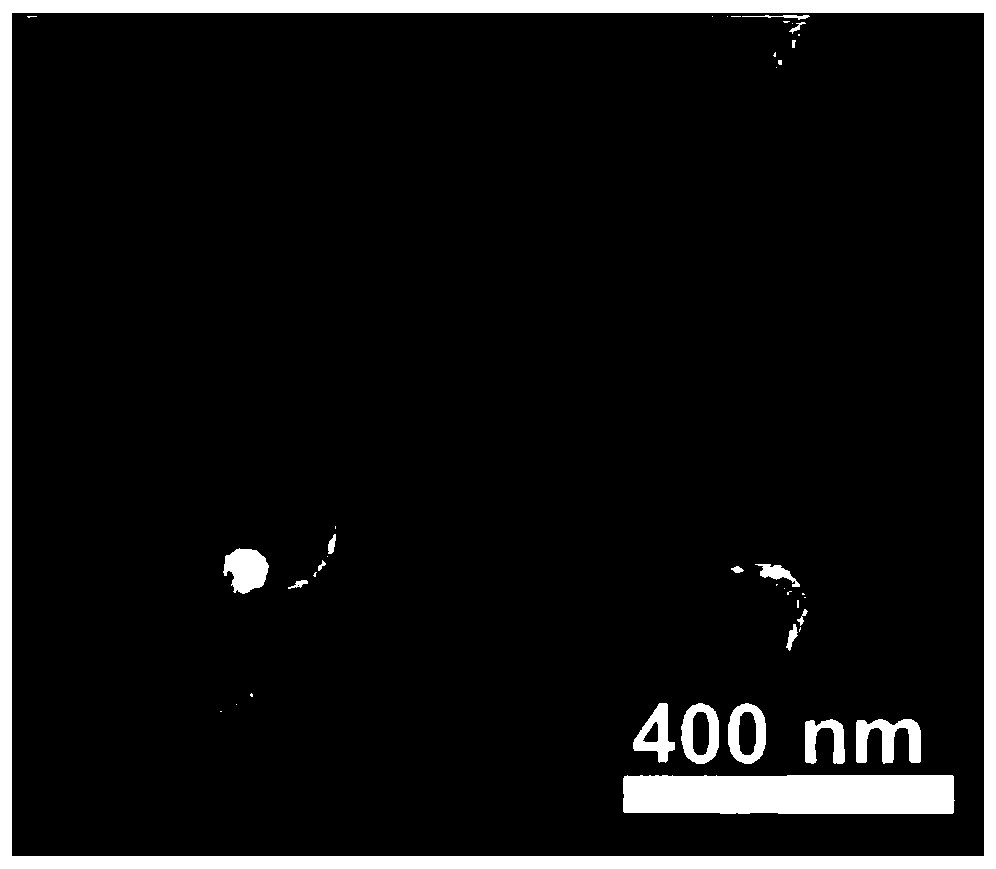

Image

Examples

Embodiment 1

[0053] (1) Dissolve 0.125g of F127 in 120ml of deionized water, stir magnetically at room temperature for 4 hours until completely dissolved; dissolve 1g of γ-cyclodextrin in the above solution, stir for 0.5h until completely dissolved, and continue stirring overnight to form a uniform and stable The precursor solution;

[0054] (2) Put the above precursor solution into a 200ml reaction kettle, heat it with constant temperature water at 220°C for 6 hours, filter / centrifuge the product after cooling, and wash the obtained product repeatedly with deionized water for 3 times, and then place the product in Dry at 60°C for 12 hours to obtain 0.2 g of brown carbon nanosphere powder;

[0055] (3) The above-mentioned brown carbon nanosphere powder was placed in a tube furnace, and the temperature was raised to 900° C. in an Ar atmosphere at a heating rate of 5° C. / min, kept for 2 hours, and then cooled with the furnace to obtain porous carbon nanospheres.

Embodiment 2

[0057] (1) Dissolve 0.125g of F127 in 120ml of deionized water, stir magnetically at room temperature for 4 hours until completely dissolved; dissolve 1g of γ-cyclodextrin in the above solution, stir for 0.5h until completely dissolved, then add 0.0833g of p-phenylenediamine, Continue to stir overnight to form a uniform and stable precursor solution;

[0058] (2) Put the above precursor solution into a 200ml reaction kettle, heat it with constant temperature water at 220°C for 6 hours, filter / centrifuge the product after cooling, and wash the obtained product repeatedly with deionized water for 3 times, and then place the product in Dry at 60° C. for 12 hours to obtain 0.33 g of brown nitrogen-doped carbon nanosphere powder;

[0059] (3) Put the above-mentioned brown nitrogen-doped carbon nanosphere powder in a tube furnace, raise the temperature to 900°C at a rate of 5°C / min in an Ar atmosphere, keep it warm for 2 hours, and then cool with the furnace to obtain nitrogen-doped...

Embodiment 3

[0061] (1) Dissolve 0.125g of F127 in 120ml of deionized water, stir magnetically at room temperature for 4 hours until completely dissolved; dissolve 1g of γ-cyclodextrin in the above solution, stir for 0.5h until completely dissolved, then add 0.1667g of p-phenylenediamine, Continue to stir overnight to form a uniform and stable precursor solution;

[0062] (2) Put the above precursor solution into a 200ml reaction kettle, heat it with constant temperature water at 220°C for 6 hours, filter / centrifuge the product after cooling, and wash the obtained product repeatedly with deionized water for 3 times, and then place the product in Dry at 60°C for 12 hours to obtain 0.45 g of brown nitrogen-doped carbon nanosphere powder;

[0063] (3) Put the above-mentioned brown nitrogen-doped carbon nanosphere powder in a tube furnace, raise the temperature to 900°C at a heating rate of 5°C / min in an argon atmosphere, keep it for 2 hours, and then cool with the furnace to obtain nitrogen-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com