Supported zeolite membranes

一种沸石分子筛、阳离子的技术,应用在制作非对称膜,制备地质聚合物组合物,非对称膜的制作,膜分离领域,能够解决存在需求等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

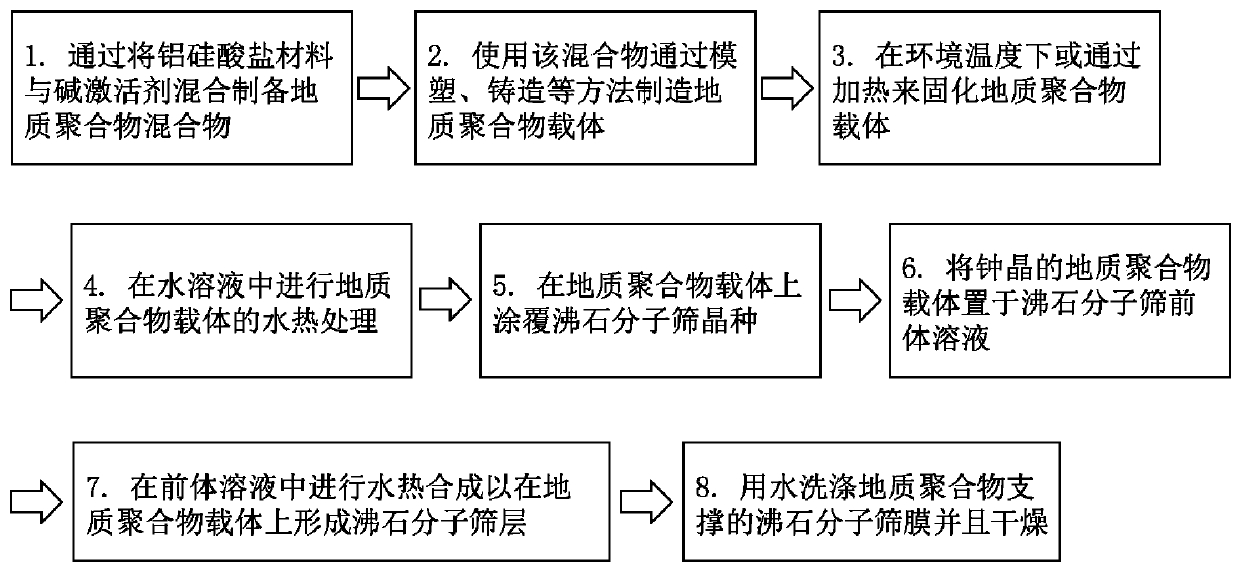

Method used

Image

Examples

Embodiment 1

[0048] Geopolymer composition: same as Comparative Example A; geopolymer curing: 24 hours at ambient temperature, then 1 hour at 60°C; geopolymer hydrothermal treatment: 24 hours in 90°C water; zeolite molecular sieve seed crystal: geopolymer water Seed crystal after heat treatment (one time); carrier masking before hydrothermal synthesis of zeolite molecular sieve: yes; composition of zeolite molecular sieve synthesis precursor solution: 2SiO 2 :Al 2 o 3 :2.1Na 2 O:140H 2 O; Zeolite molecular sieve membrane hydrothermal synthesis: 8 hours in zeolite molecular sieve synthesis solution at 90°C.

[0049] In this example, the geopolymer composition was prepared in the same manner as Comparative Example A. After mixing, the geopolymer mixture was cast into disc-shaped molds with a diameter of 25 mm and a thickness of 3 mm. The disc molds were sealed and cured at room temperature for 24 hours, then at 60°C for 1 hour before demoulding. XRD analysis shows that the carrier is a...

Embodiment 2

[0054] Membrane production is the same as in Example 1, except for the following: geopolymer solidification: 60°C for 24 hours; zeolite molecular sieve membrane hydrothermal synthesis: zeolite molecular sieve synthesis solution at 90°C for 6 hours.

[0055] In this example, a geopolymer carrier was fabricated in the same manner as in Example 1, except that geopolymer curing was performed at 60° C. for 24 hours. XRD analysis showed that the support was an amorphous geopolymer after solidification with some quartz impurity peaks, and faujasite molecular sieves appeared after hydrothermal treatment of the geopolymer in water at 90 °C for 24 hours. In this example, the production of the zeolite molecular sieve membrane on the geopolymer carrier is the same as in Example 1, except that the zeolite hydrothermal synthesis is carried out at 90° C. for 6 hours. The XRD analysis of the zeolite molecular sieve membrane supported on the geopolymer carrier showed that after the zeolite mol...

Embodiment 3

[0058] Membrane production is the same as in Example 2, except for the following: carrier masking before zeolite molecular sieve hydrothermal synthesis: none; zeolite molecular sieve membrane hydrothermal synthesis: 8 hours in zeolite molecular sieve synthesis solution at 90°C.

[0059]In this example, a geopolymer carrier was fabricated in the same manner as in Example 2. In this example, the manufacture of the zeolite molecular sieve membrane on the geopolymer carrier is the same as in Example 2, except that the geopolymer carrier is used directly without any surface masking and the hydrothermal synthesis of the zeolite molecular sieve is carried out at 90°C for 8 Hour.

[0060] Membrane dehydration performance evaluation was carried out in the same manner as in Example 1. The separation factor of the zeolite molecular sieve membrane manufactured in this example is greater than 10000 at 50°C in terms of separating 90% ethanol and 10% water, and the permeation flux is 2.2kg / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com