Nanofiltration membrane material with high surface roughness and preparation method thereof

A technology with roughness and high surface, applied in the field of membrane separation, can solve the problems of low permeation flux and unable to meet production needs, and achieve the effect of strong hydrophilicity, improved retention rate and permeability, and small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

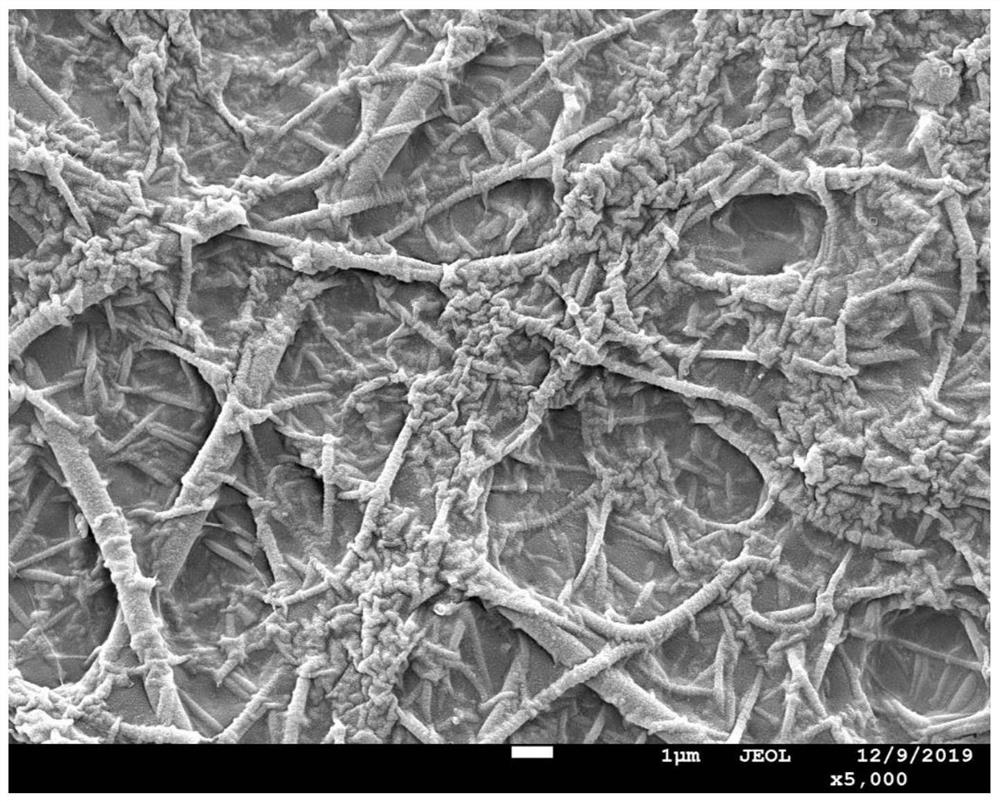

Image

Examples

Embodiment 1

[0028] This embodiment provides a nanofiltration membrane material with high surface roughness, which is composed of a nanofiber coating film with high surface roughness and a polypiperazine amide nanofiltration separation layer on its surface; The nanofiber coating membrane with surface roughness is composed of a polymer microfiber nonwoven material and a polymer nanofiber coating with high surface roughness coated on its surface, and the nanofiltration separation layer is passed through by the water phase and the oil phase Formed by in-situ interfacial polymerization, the surface layer nanofibers of the polymer nanofiber coating with high surface roughness are wrapped and covered by the polypiperazine amide nanofiltration separation layer.

[0029] The polymer microfiber nonwoven material is a spunbonded nonwoven material of polyester; the polymer nanofiber coating with high surface roughness is a dense coating composed of nanofibers with a diameter variation coefficient of 3...

Embodiment 2-5

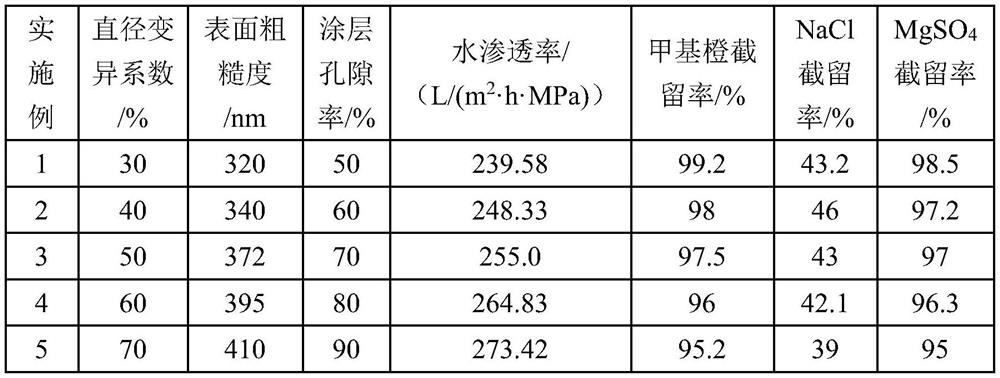

[0039] Embodiment 2-5 provides a kind of nanofiltration membrane material of high surface roughness, compared with embodiment 1, difference is: change the diameter variation coefficient of polymer nanofiber in described polymer nanofiber coating, the other It is the same as in Example 1, and will not be repeated here. The specific experimental conditions and measurement results are shown in the table below.

[0040]

[0041] As can be seen from the results in the table above, changing the coefficient of variation of the diameter of the ethylene-vinyl alcohol copolymer nanofibers will affect the surface roughness, porosity and water permeability of the nanofiltration membrane of the polymer nanofiber coating base film. With the increase of the diameter variation coefficient of ethylene-vinyl alcohol copolymer nanofibers, the surface roughness of the nanofiber coating base membrane increases, and at the same time, the nanofiltration The water permeability of the membrane is s...

Embodiment 6~8

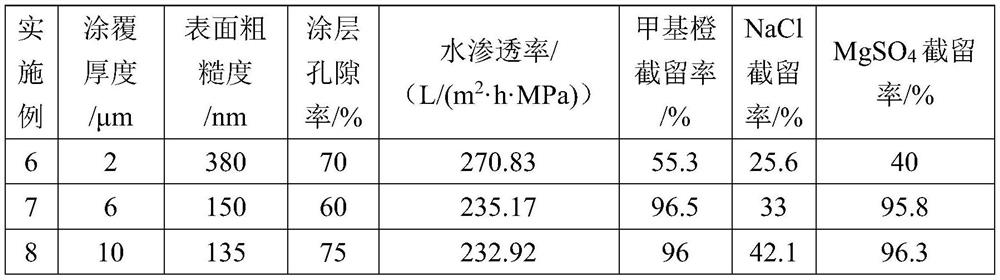

[0043] Embodiment 6~8 provide a kind of nanofiltration membrane material of high surface roughness, compared with embodiment 1, difference is: change the nanofiber coating thickness of described high surface roughness, all the other are the same as embodiment 1 Same, no more details here, specific experimental conditions and measurement results are shown in the table below.

[0044]

[0045] As can be seen from the results in the table above, under the condition that the coefficient of variation in diameter is 30%, changing the coating thickness of the polymer nanofiber dispersion on the surface of the nonwoven substrate will affect the surface roughness of the polymer nanofiber coating base film. , porosity, and the water permeability and retention performance of the prepared nanofiltration membrane have a significant impact. With the increase of the coating thickness of the nanofiber dispersion on the surface of the non-woven substrate, the surface of the nanofiber coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com