Preparation method of porous WO3/C nanosheet mesoporous composite photocatalyst

A technology of nanosheets and composite light, which is applied in the field of photocatalysis and photoelectrochemical materials, can solve the problems of insufficient photoelectric performance and low photocatalytic efficiency, and achieve the effect of good light absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of porous WO 3 The preparation method of / C nanosheet mesoporous composite photocatalyst comprises the following steps:

[0022] 0.1gWO 3 2H 2 O / n-propylamine inorganic / organic layered hybrids are added into the porcelain boat, and then the porcelain boat is put into the tube furnace and nitrogen gas is introduced. Set the heating rate to 10°C / min, the heating time to 40min, heat to 400°C, and the holding time to 2h. After the reaction, let it cool down to room temperature naturally, and take out the porous WO 3 / C nanosheet mesoporous composite photocatalyst material.

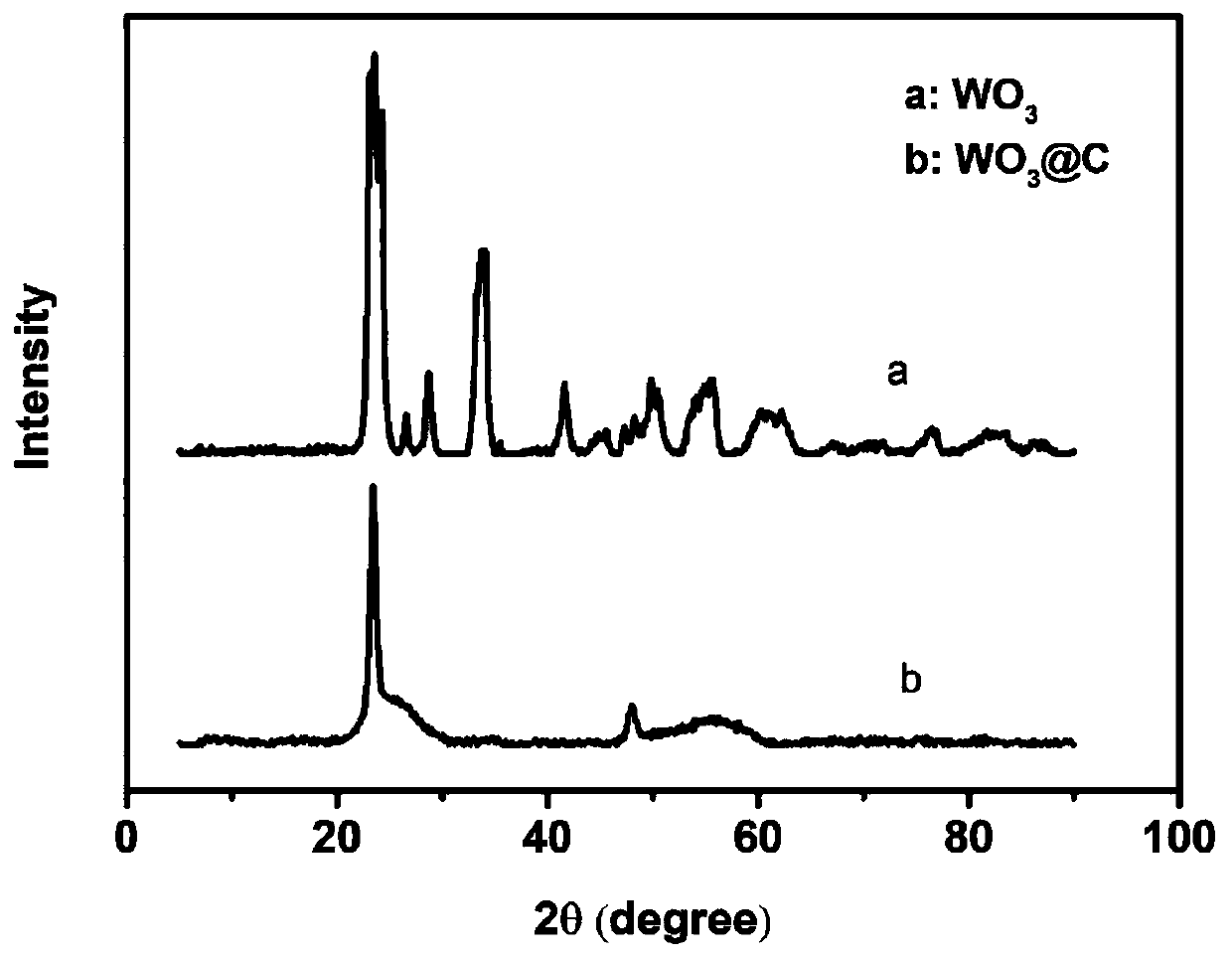

[0023] Porous WO in this embodiment 3 / C nanosheet mesoporous composite photocatalyst material XRD patterns, such as figure 1 Shown; Porous WO 3 / C nanosheet mesoporous composite photocatalyst material TEM images, such as figure 2 Shown; Porous WO 3 SEM images of / C nanosheet mesoporous composite photocatalyst materials at different magnifications, such as image 3 Shown, among them (a...

Embodiment 2

[0025] A kind of porous WO 3 The preparation method of / C nanosheet mesoporous composite photocatalyst comprises the following steps:

[0026] 0.5gWO 3 2H 2 O / n-butylamine inorganic / organic layered hybrids are added into the porcelain boat, and then the porcelain boat is put into the tube furnace and nitrogen gas is introduced. Set the heating rate to 25°C / min, the heating time to 40min, heat to 600°C, and the holding time to 4h. After the reaction, let it cool down to room temperature naturally, and take out the porous WO 3 / C nanosheet mesoporous composite photocatalyst material.

Embodiment 3

[0028] A kind of porous WO 3 The preparation method of / C nanosheet mesoporous composite photocatalyst comprises the following steps:

[0029] 0.2gWO 3 2H 2 O / n-octylamine inorganic / organic layered hybrids are added to the porcelain boat, and then the porcelain boat is put into the tube furnace and nitrogen gas is introduced. Set the heating rate to 15°C / min, the heating time to 40min, heat to 500°C, and the holding time to 3h. After the reaction, let it cool down to room temperature naturally, and take out the porous WO 3 / C nanosheet mesoporous composite photocatalyst material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com