Flotation coal slime collecting agent, preparation method and uses thereof

A collector and coal slime technology, applied in flotation, solid separation, etc., can solve the problems of unreasonable recovery and utilization of residual liquid, troublesome separation and recovery, and poor economic benefits, so as to broaden the source of raw materials and achieve high recovery rate , Improve the effect of sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

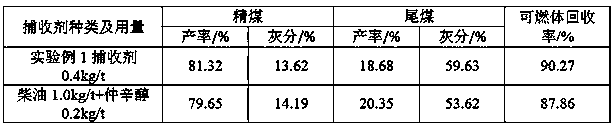

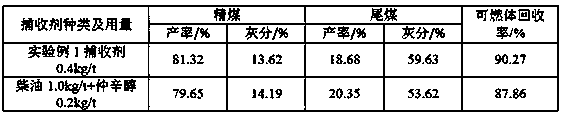

Examples

Embodiment 1

[0022] Embodiment 1, a kind of flotation coal slime collector: it is made by the raw material of following mass ratio, octene formylation residual liquid, C 1~6 Short-chain alcohol, catalyst=100:10:0.1; The catalyst is one of concentrated sulfuric acid, concentrated hydrochloric acid, phosphoric acid, p-toluenesulfonic acid or solid acid.

Embodiment 2

[0023] Embodiment 2, a kind of flotation coal slime collector: it is made by the raw material of following mass ratio, octene formylation residual liquid, C 1~6 Short-chain alcohol, catalyst = 100: 150: 5; The catalyst is a mixed acid of any two of concentrated sulfuric acid, concentrated hydrochloric acid, phosphoric acid, p-toluenesulfonic acid or solid acid, each accounting for 50%.

Embodiment 3

[0024] Embodiment 3, a kind of flotation coal slime collector: it is made by the raw material of following mass ratio, octene formylation residual liquid, C 1~6 Short chain alcohol, catalyst=100:50:0.5; The catalyst is concentrated sulfuric acid or concentrated hydrochloric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com