A kind of water-resistant sandpaper and preparation method thereof

A sandpaper and sand planting technology, applied in the field of sandpaper, can solve the problems of low grinding efficiency, insufficient water resistance, and high brittleness of coarse-grained sandpaper, achieving good cutting ability, reducing employee health and environmental hazards, and good flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

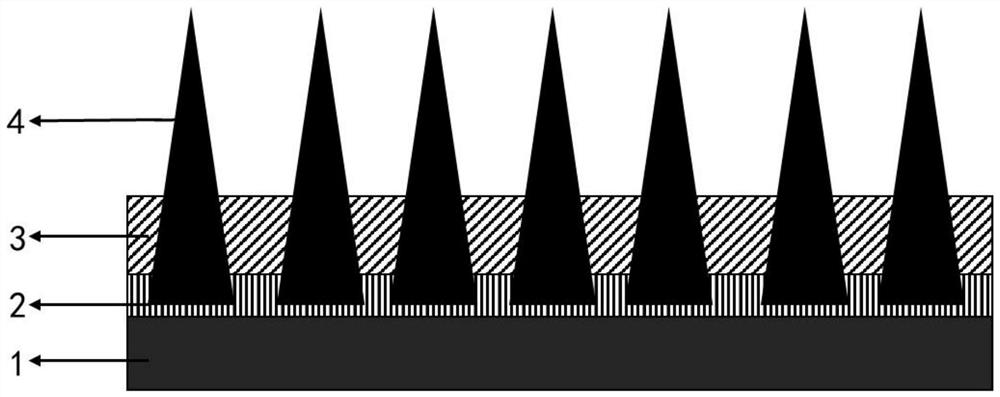

[0056] A kind of water-resistant sandpaper, comprising a base material and several abrasive materials 4 evenly planting sand on the base material, the base material includes a paper base layer 1, a primer layer 2 and a glue layer 3 arranged sequentially from bottom to top, the The lower part of the abrasive material 4 runs through the sizing layer 3 , the bottom end of the lower part of the abrasive material 4 is embedded in the primer layer 2 , and the upper part of the abrasive material 4 protrudes from the upper surface of the sizing layer 3 . That is, the lower part of the abrasive material 4 is embedded in the oversize layer 3 and the primer layer 2 , and the upper part of the abrasive material 4 protrudes from the oversize layer 3 and the undercoat layer 2 .

[0057] The abrasive material 4 is silicon carbide, the vertical section of the abrasive material 4 is an equiangular triangle, and the tip part of the upper part of the abrasive material 4 protrudes from the upper s...

Embodiment 2

[0080] The difference between this embodiment and above-mentioned embodiment 1 is:

[0081] Described compound glue layer 3 is made after being coated with compound glue, and described compound glue comprises the raw material of following weight portion:

[0082]

[0083] The coupling agent is 3-(2,3-glycidoxy)propyltrimethoxysilane; the wetting agent is polyoxyethylene fatty alcohol ether.

[0084] The defoamer is polyoxyethylene polyoxypropylene pentaerythritol ether; the solvent A is a mixture of absolute alcohol and water in a weight ratio of 1:1.8.

[0085] Described primer layer 2 is made after being coated with primer, and described primer comprises the raw material of following weight portion:

[0086] Epoxy resin E-51 52 parts

[0087] Polyamide resin 650 98 parts

[0088] 6 parts of solvent B.

[0089] The molecular weight of the polyamide resin 650 is 700, and the solvent B is a mixture of xylene, n-butanol and acetone in a weight ratio of 1:1:1.

[0090] The ...

Embodiment 3

[0102] The difference between this embodiment and above-mentioned embodiment 1 is:

[0103] Described compound glue layer 3 is made after being coated with compound glue, and described compound glue comprises the raw material of following weight portion:

[0104]

[0105] The coupling agent is 3-(2,3-glycidoxy)propyltrimethoxysilane; the wetting agent is Span-20.

[0106] The defoamer is a W090 type defoamer; the solvent A is a mixture of absolute alcohol and water in a weight ratio of 1:2.

[0107] Described primer layer 2 is made after being coated with primer, and described primer comprises the raw material of following weight portion:

[0108] Epoxy resin E-51 55 parts

[0109] Polyamide resin 650 100 parts

[0110] 8 parts of solvent B.

[0111] The molecular weight of the polyamide resin 650 is 800, and the solvent B is a mixture of xylene, n-butanol and acetone in a weight ratio of 1:1:1.

[0112] The silicon carbide is a modified silicon carbide that has been m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com