Modified recycled coarse aggregate, permeable water storage concrete and preparation method thereof

A technology of recycled coarse aggregate and concrete, which is applied in the field of permeable water-storage concrete and its preparation, and modified recycled coarse aggregate. It can solve the problems of permeable concrete that can only permeate water but not store water, and reduce its strength, so as to adjust the surrounding temperature and humidity. Good, increased early strength, permeable weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

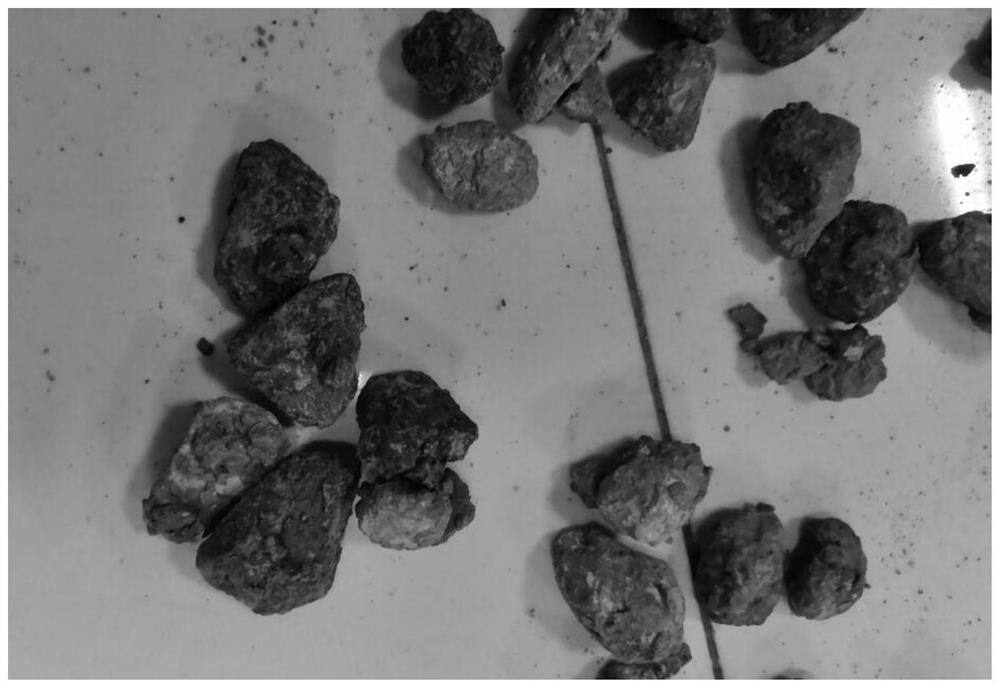

[0028] my country's construction waste has accounted for 30% to 40% of urban waste, and the annual discharge of construction waste has reached 400 million tons per year. At present, my country's construction waste is mostly disposed of in the form of open-air stacking. Harmful components in construction waste and small-sized gravel will seep into the nearby soil, causing pollution and damage to the soil structure. Therefore, the present invention adopts discarded bricks and cement blocks as coarse aggregate, and since the cylinder compressive strength of waste and old blocks is about 3MPa, it is modified by the method of the present invention, and the strength of the modified coarse aggregate can reach About 5MPa. The preparation method of modified recycled coarse aggregate of the present invention comprises the following processes:

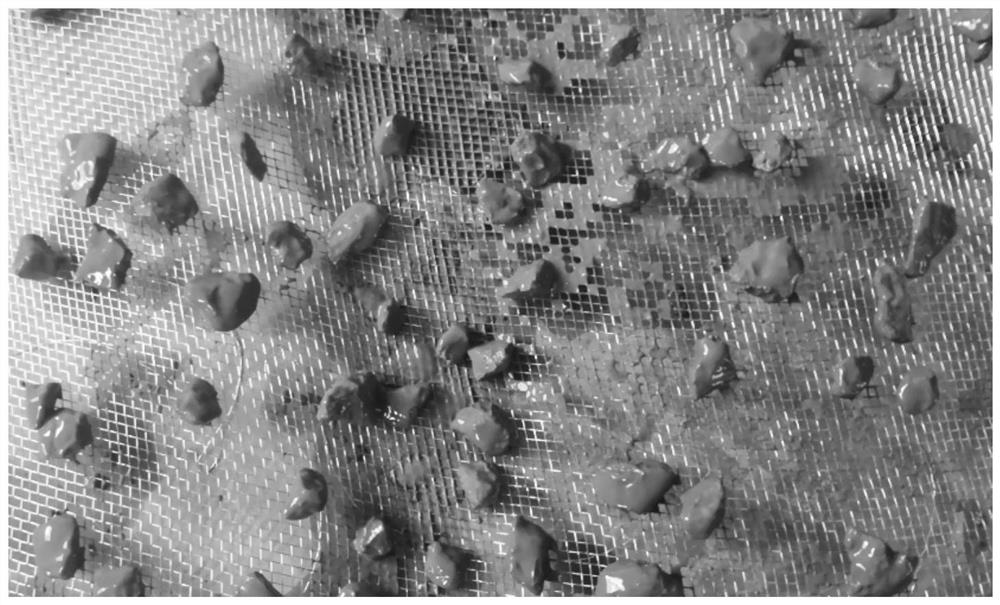

[0029] Step 1: Break waste and old blocks into granular shapes with a particle size of 4.5 to 16.0 mm, then saturate the granular blocks with w...

Embodiment 1

[0044] This example discloses a modified recycled aggregate and its preparation method, which is made by the following method:

[0045] Step 1: Use a crusher to break the bricks into bricks with two particle sizes of 4.5-9.5mm and 9.5-16.0mm; saturate the broken bricks with water, and then dry the bricks with a wet cloth;

[0046] Step 2: Weigh the quality of cement according to the mass ratio of dry bricks to cement, wherein the mass ratio of dry bricks to cement is 1.69:1; the water-cement ratio of cement is 0.27. Mix the saturated surface dry bricks with cement evenly (manual mixing), add water after mixing evenly, and manually mix for 15 minutes. Spread the mixed aggregates on the flat cement floor (thin layer), and after the cement sets and hardens (about 2 hours), separate the bonded aggregates and dry them in the air;

[0047] Step 3: After 24 hours, perform secondary wrapping according to the wrapping process of step 2. After wrapping for 24 hours, sieve the modified ...

Embodiment 2

[0059] This example discloses a permeable water-storage concrete and its preparation. The raw materials for the preparation of the permeable water-storage concrete include 20% modified recycled coarse aggregate, 47.77% waste concrete coarse aggregate, 26% cement, and 6.2% water , 0.03% of the water reducing agent, the sum of the mass percentages of raw materials is 100%.

[0060] The preparation process of permeable water storage concrete is as follows:

[0061] Put the waste concrete into the crusher for crushing, and sieve the crushed aggregate into two grades of 4.5-9.5mm and 9.5-16.0mm. Then, the modified recycled coarse aggregate with a particle size of 4.5-9.5mm obtained in Example 1 and the waste concrete coarse aggregate with a particle size of 4.5-9.5mm are uniformly mixed in a volume ratio of 3:2 to obtain a particle size The mixed coarse aggregate is 4.5-9.5mm; the same method is used to prepare the mixed coarse aggregate with a particle size of 9.5-16.0mm; it can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com