Continuous preparation method of high-content 2-chloroethanol

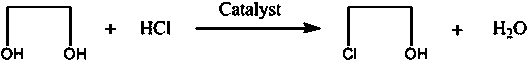

A technology with high content of chloroethanol, which is applied in the preparation of organic compounds, the preparation of halogens, and the preparation of hydroxyl compounds. It can solve the problems of obvious heat release, flammability, explosion, and toxicity, so as to improve the utilization rate and reduce the cost of raw materials. , the effect of high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

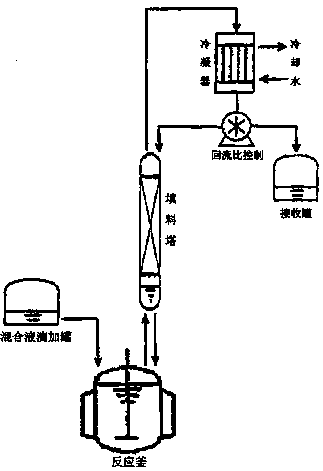

Method used

Image

Examples

Embodiment 1

[0029] Put 330g of ethylene glycol, 200g of hydrochloric acid (36%), 51g of water and 39g of adipic acid into the reaction kettle, stir and raise the temperature, until the temperature in the kettle reaches 110°C and reflux occurs, drop into the kettle at a rate of 150g / h Mixed solution (ethylene glycol: 36% hydrochloric acid: the weight ratio of water is 2.2: 3.6: 1). When the condensate just appears in the top condenser, turn on the reflux ratio control immediately, keep the reflux ratio 2:3 and the temperature in the kettle at 113±3°C to obtain the crude product of 2-chloroethanol, the content is 42%, and the acid value (calculated as HCl ) was 0.07%, and the yield of 2-chloroethanol (calculated as HCl) in the reaction stage reached 99.3%.

[0030] Put 800g of the above-mentioned crude product and 240g of water-carrying benzene into the rectification kettle, heat and keep the top temperature at 67-72°C, distill at atmospheric pressure, and remove the lower layer of water by...

Embodiment 2

[0033] Put 500g of ethylene glycol, 303g of hydrochloric acid (36%), 77g of water and 59g of adipic acid into the reaction kettle, stir and raise the temperature, until the temperature in the kettle reaches 110°C and reflux occurs, drop into the kettle at a rate of 180g / h Mixed solution (ethylene glycol: 36% hydrochloric acid: the weight ratio of water is 2.2: 3.6: 1). When the condensate just appeared in the top condenser, turn on the reflux ratio control immediately, keep the reflux ratio 2:3 and the temperature in the kettle at 115±3°C, and obtain the crude product of 2-chloroethanol, the content is 41.8%, the acid value (calculated by HCl ) was 0.07%, and the yield of 2-chloroethanol (calculated as HCl) in the reaction stage reached 99%.

[0034] Put 800g of the above-mentioned crude product and 240g of water-carrying agent benzene into the rectification kettle, and dehydrate at the top temperature of 67-72°C. Remove benzene at a kettle temperature of 110-130°C.

[0035]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com