Deep blind hole inner wall laser cladding device

A laser cladding and deep blind hole technology, applied in metal material coating process, coating and other directions, can solve the problems of cladding processing, the inner wall of the root of the deep blind hole cannot be used, and the efficiency of laser cladding is low, so as to improve the efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

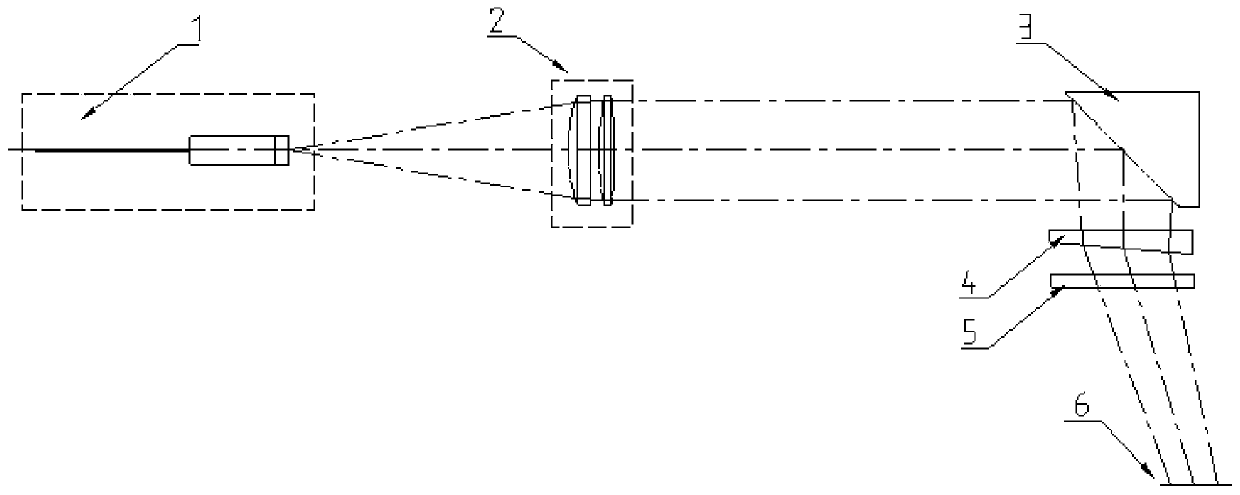

[0023] Such as figure 1 As shown, a laser cladding device for the inner wall of a deep blind hole includes a fiber laser 1 with a fiber interface and a laser beam outlet, a collimator group 2, an integrator 3, and an optical wedge arranged in sequence along the beam propagation direction of the fiber laser 1 4. Protective lens 5. The laser beam with a certain angle emitted by the laser is collimated into a parallel circular beam by the collimator lens group 2. The collimator lens group 2 can be composed of a lens or a group of lenses; The light beam is reflected by the integrating mirror 3, and the light spot at the melting pool becomes the required rectangular light spot after reflection, and after the light beam is reflected by the integrating mirror 3, the propagation direction of the light beam is deflected by 90°, and the whole light beam is deflected by a certain angle through the optical wedge 4, reaching The inner wall 6 (working surface) of the root of the processed d...

Embodiment 2

[0026] Such as figure 1 As shown, a laser cladding device for the inner wall of a deep blind hole includes a semiconductor laser with optical fiber output, a collimator lens group 2, an integrator mirror 3, an optical wedge 4, a protective lens 5, and a laser The emitted laser beam with a certain angle is collimated into a parallel circular beam by the collimator lens group 2, which can be composed of a lens or a group of lenses; the parallel circular beam is reflected by the integrator mirror 3, After reflection, the light spot at the molten pool becomes the required rectangular light spot, and after the integrator mirror 3 reflects the beam propagation direction and deflects 90°, the light beam is deflected by a certain angle through the optical wedge 4 to reach the processed deep blind hole. The inner wall 6 (working surface) of the root, so that the inner wall of the deep blind hole is completely clad, and the protective lens 5 is located below the optical wedge 4 (in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com