Gear suspension and gear drive load balancing pumping unit

A gear-driven, load-balancing technology, used in machines/engines, liquid-variable-capacity machinery, and mechanical equipment, etc., can solve problems such as limited space for improvement in machine mining efficiency and energy-saving potential, uneven load on up and down strokes, and inability to overcome congenital deficiencies. , to achieve the effect of small rotating force arm, small installed power and short transmission chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

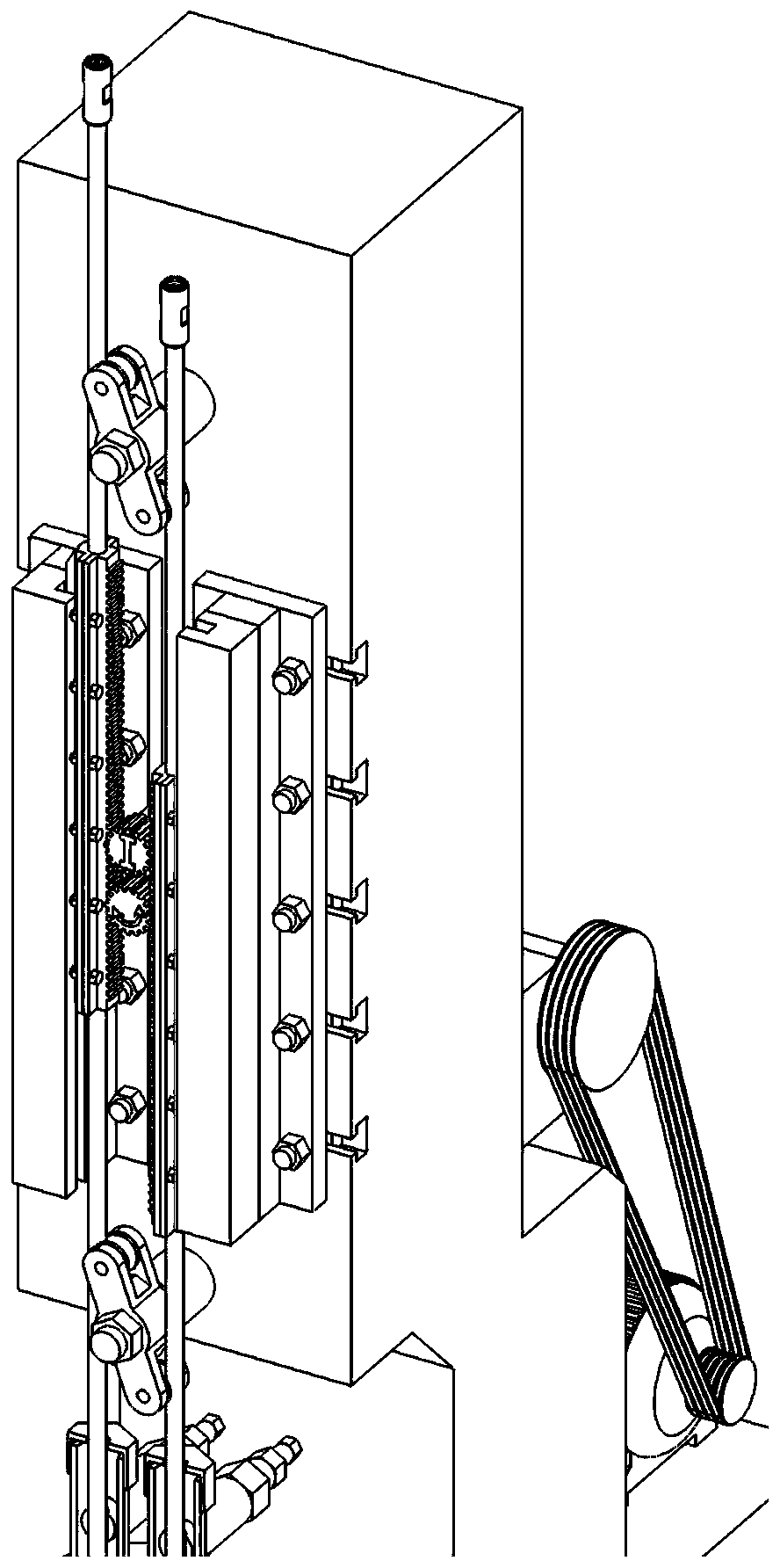

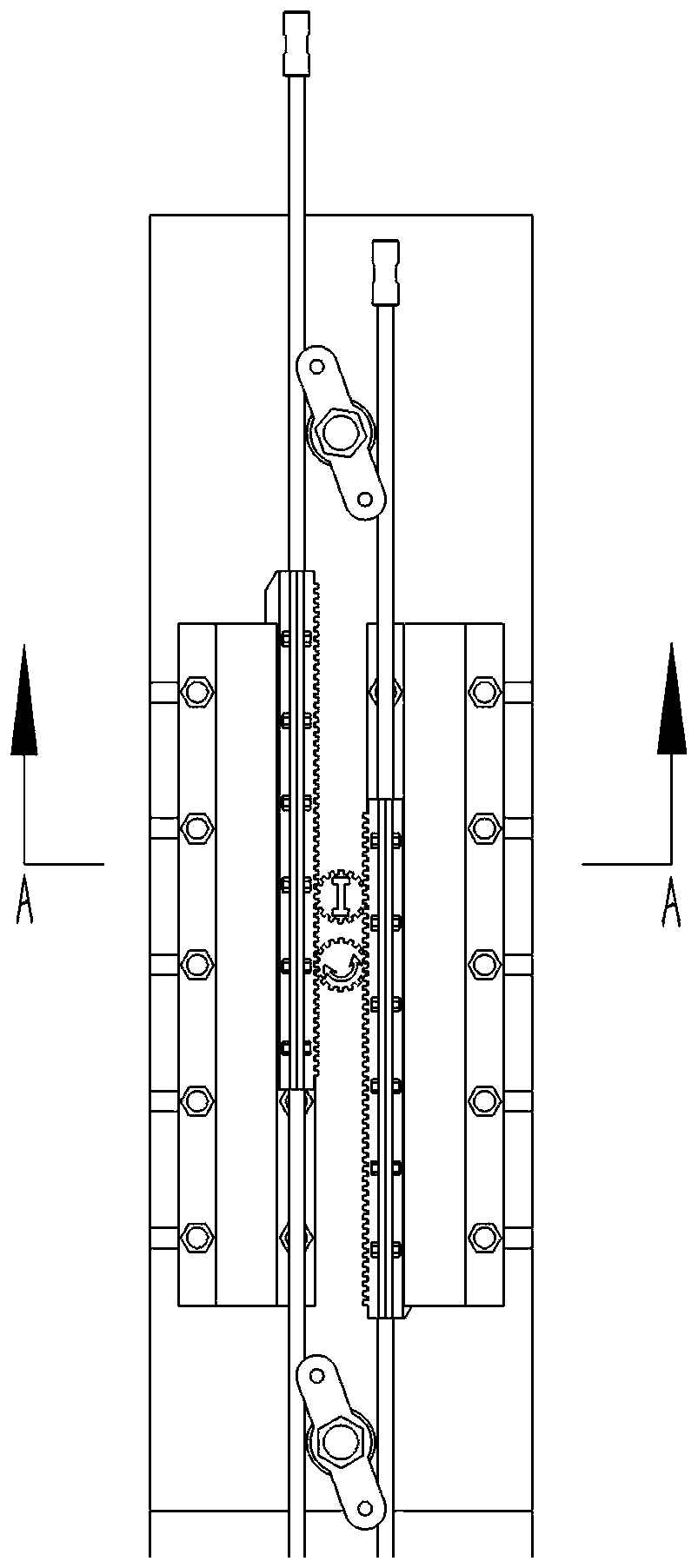

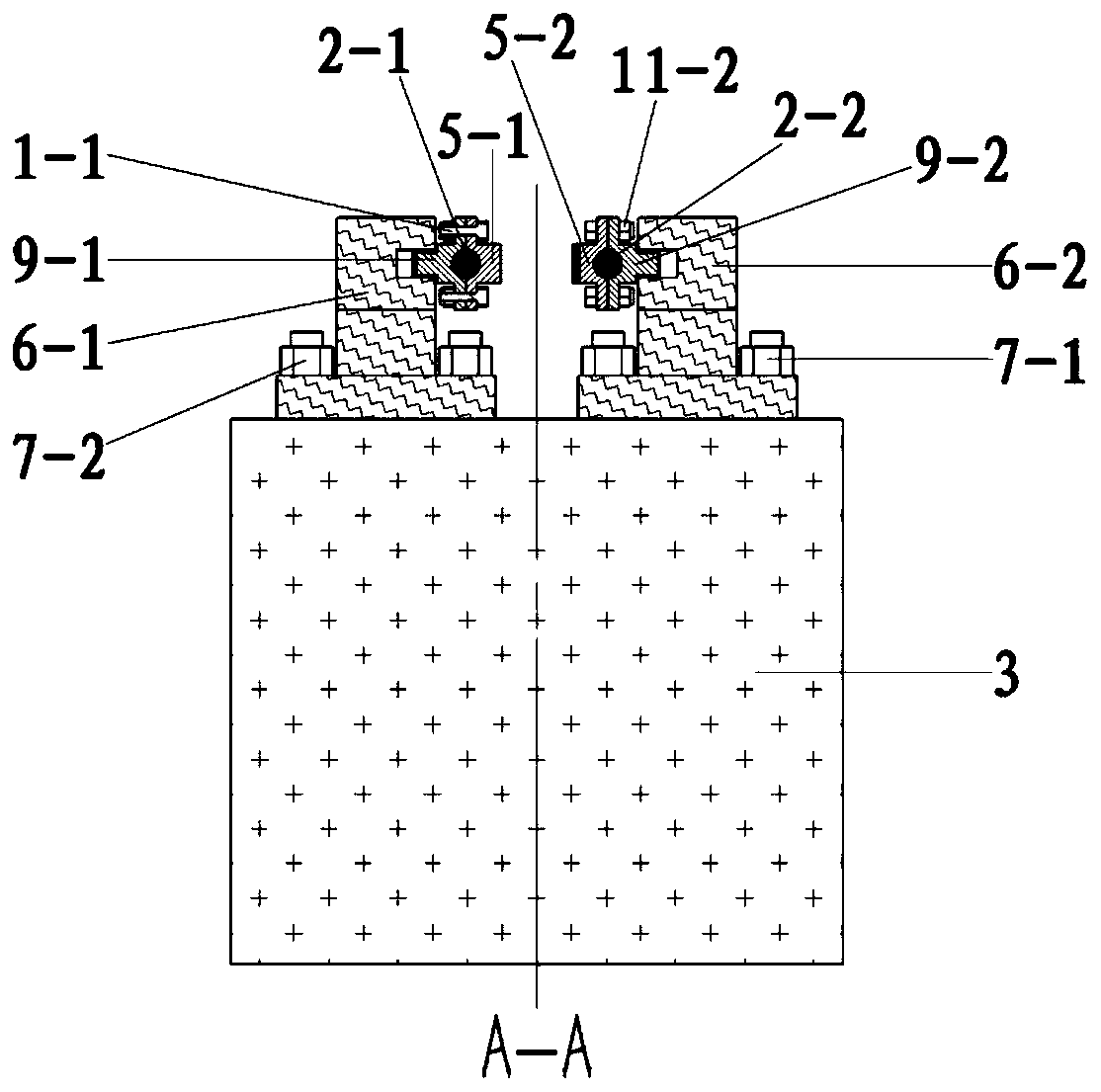

[0025] The gear suspension-gear drive mirrored double suspension pumping unit provided in this embodiment, the gear suspension gear drive load balance pumping unit includes a frame 3 and a double rack up and down drive device installed on the frame, the double The rack up and down driving device includes polished rod elevating racks (5-1, 5-2) respectively fixedly connected with a polished rod, polished rod elevating guide rails (9-1, 9-2) respectively fixedly connected with polished rod elevating racks, respectively The rack guide rail (6-1, 6-2) configured with the polished rod lifting guide rail, the drive gear 10 that meshes with the two lifting racks at the same time and drives the two lifting racks to move alternately up and down, the motor 42, the gearbox 39, the motor The output shaft of 42 links to each other with gearbox input shaft pulley 40 by belt 41. The two ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap