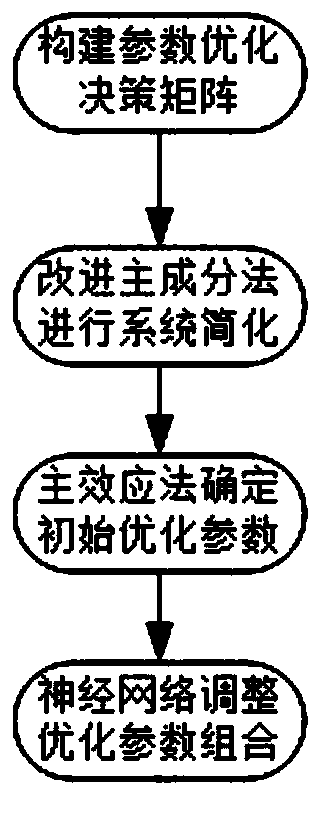

Parameter optimization method based on improved principal component method

An optimization method and principal component technology, applied in the direction of comprehensive factory control, instrumentation, and comprehensive factory control, etc., can solve the problems that affect the results of parameter optimization design, limit the range of parameter optimization optimization, and the parameter design results are not reliable enough. The effect of clear display, improved robustness and production cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

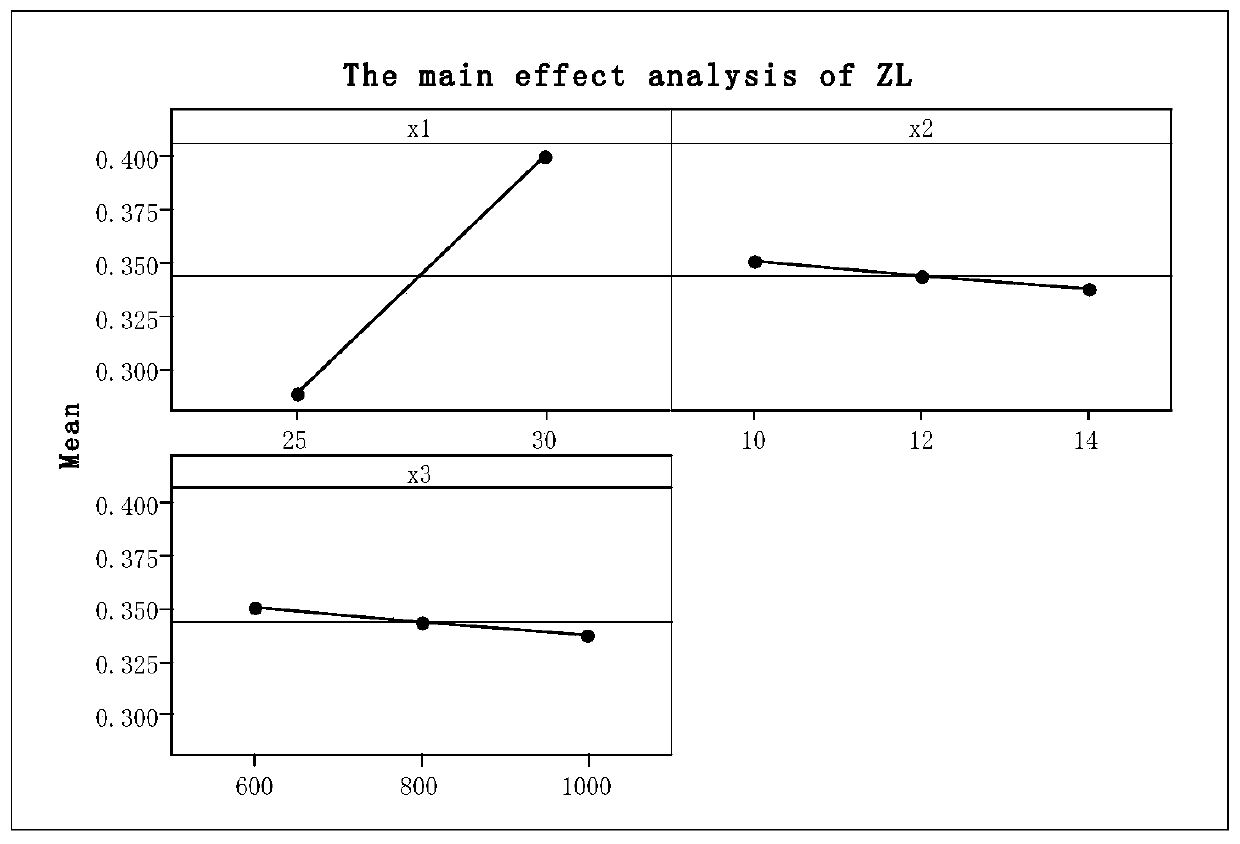

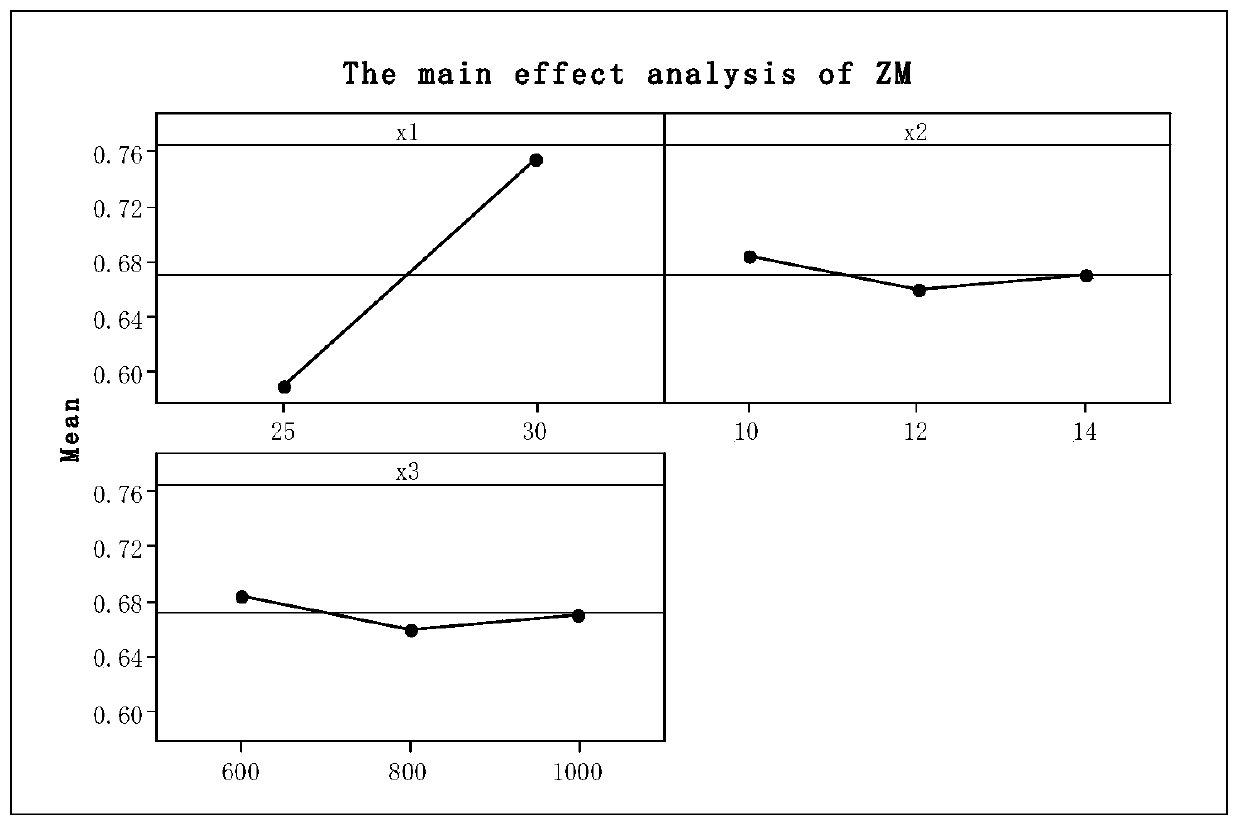

[0105] With the development and progress of intelligent production technology, in the automated manufacturing industry, the tool status not only affects the processing quality and production efficiency, but also has a certain early warning effect on the prevention of machine tool accidents for important personnel in production. Therefore, tool status monitoring is becoming more and more important. To ensure that the tool state can be stably maintained within a controllable range, in order to achieve the effect of improving the processing quality of the tool, it is usually necessary to optimize the design of the tool parameters. In the drilling production process, in order to improve the drilling quality, the helix angle (x 1 ), feed rate (x 2 ) and spindle speed (x 3 ) cutting parameters as control variables, the surface roughness (y 1 ), tool wear (y 2 ) and tool vibration (y 3 ) machining characteristics as the response variable, reflecting the machining efficiency of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com