Nanoparticle self-assembled transparent circuit board, and preparation method thereof and application thereof

A transparent circuit board and nanoparticle technology, applied in the field of microelectronics, can solve the problems of single production substrate, circuit structure control, cumbersome production steps, etc., and achieve the effect of simple production, low cost and good optical transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

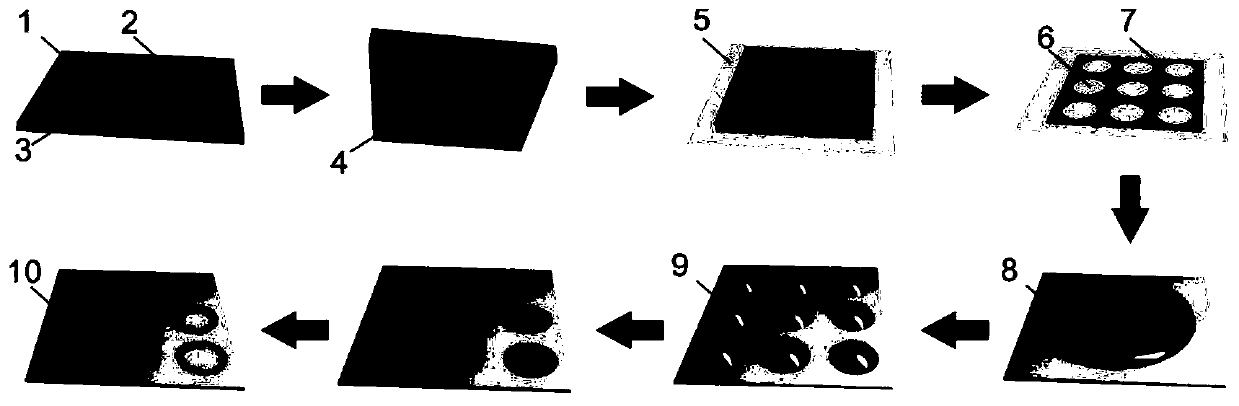

[0041] According to another aspect of the present invention, a method for preparing a nanoparticle self-assembled transparent circuit is provided, comprising the following steps:

[0042] (a) Fabrication of micropatterned PDMS stamps using standard photolithography and rapid imprinting;

[0043] (b) Sandwich the commercial parafilm between the tinfoil and the PDMS stamp obtained in step (a), and place the device with a sandwich structure (the PDMS stamp is on the top layer) on a hot plate and heat at 120°C for 30s;

[0044] (c) tear the PDMS stamp obtained in step (b) off the sealing film, and immediately place it on the target substrate, press the PDMS stamp with your fingers for about 30 seconds at room temperature, and then tear the PDMS stamp off the target substrate;

[0045] (d) adding the water-soluble solution containing nanoparticles to the target substrate obtained in step (c), and using a glass rod to guide the nanoparticle suspension to move over the surface of the t...

Embodiment 1

[0049] A transparent circuit board self-assembled by nanoparticles, the transparent circuit board includes a nanoparticle conductive structure self-assembled based on the coffee ring effect and a hydrophilic transparent substrate; the nanoparticle conductive structure is a hollow structure obtained by self-assembly by the coffee ring effect; The nano particle conductive structure is located on the surface of the hydrophilic transparent substrate; the nano particle conductive structure is distributed in an array.

[0050] The nanoparticles are gold nanoparticles.

[0051] The hydrophilic transparent base is a plastic petri dish; the boundary shape of the hollow structure is a circle.

[0052] The height of the nanoparticle conductive structure is 100 nm, and the boundary width is 1 μm.

[0053] Each conductive nanoparticle structure is located in a square area with a side length of 400 μm, and the distance between centers of gravity of adjacent conductive nanoparticle structur...

Embodiment 2

[0055] A transparent circuit board self-assembled by nanoparticles, the transparent circuit board includes a nanoparticle conductive structure self-assembled based on the coffee ring effect and a hydrophilic transparent substrate; the nanoparticle conductive structure is a hollow structure obtained by self-assembly by the coffee ring effect; The nano particle conductive structure is located on the surface of the hydrophilic transparent substrate; the nano particle conductive structure is distributed in an array.

[0056] The nanoparticles are gold nanoparticles.

[0057] The hydrophilic transparent substrate is glass; the boundary shape of the hollow structure is square.

[0058] The height of the nanoparticle conductive structure is 300 nm, and the boundary width is 3 μm.

[0059] Each of the nanoparticle conductive structures is located in a square area with a side length of 500 μm, and the distance between the centers of gravity of adjacent nanoparticle conductive structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com