Preparation process of composite vegetable-oil sunscreen cream

A preparation process and sunscreen technology, which is applied in the field of compound vegetable oil sunscreen preparation process, can solve the problems of skin anti-inflammation and pain relief, sunscreen's weak ability to absorb ultraviolet rays, etc., and achieve the effect of improving the mixing effect, improving the mixing efficiency and avoiding the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

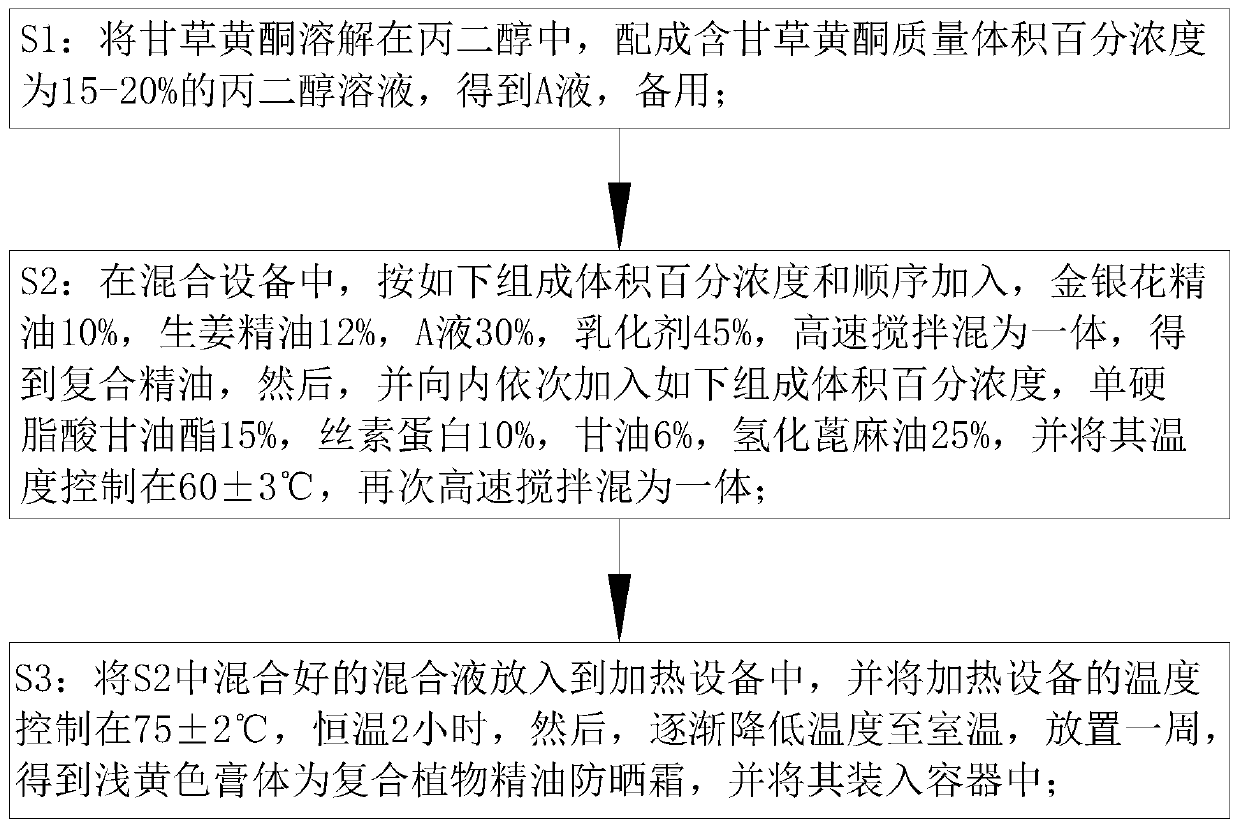

Method used

Image

Examples

Embodiment approach

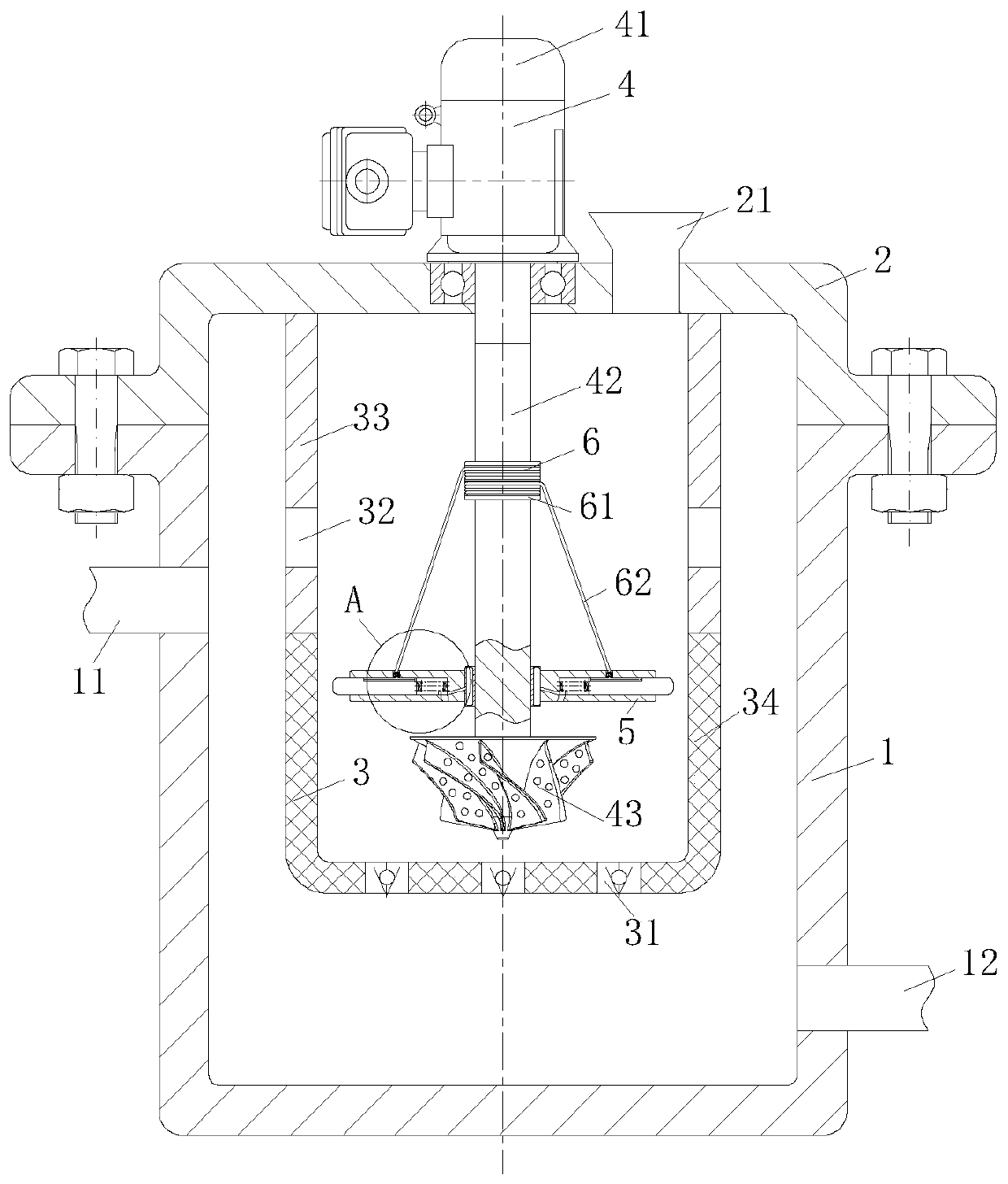

[0033] As a specific embodiment of the present invention, the first rod 52 is composed of the second rod 521 and the third rod 522, and both the second rod 521 and the third rod 522 are located in the elastic cylinder 34; the second rod One end of 521 is fixedly connected on the mounting plate 51, and the other end is provided with a groove, and a side surface of the second rod 521 is provided with a groove; the third rod 522 is fixedly connected on the inner wall of the groove by a spring; The No. 1 slot is provided with an adjustment unit 6, and the adjustment unit 6 is used to adjust the movement of No. 3 rod 522 in the groove; by setting No. 1 rod 52 to be composed of No. 2 rod 521 and No. 3 rod 522, by The adjustment of the adjustment unit 6 realizes the expansion and contraction of the third rod 522; when the third rod 522 moves to the side close to the elastic cylinder 34, the inner wall of the elastic cylinder 34 expands outward, and accelerates the shaking of the elast...

specific Embodiment approach

[0036] As a specific embodiment of the present invention, the No. 3 hole 523 is arranged obliquely, and the inclination angle of the No. 3 hole 523 is gradually inclined to the side close to the No. 1 shaft 42 from top to bottom; TiO 2 All converge toward the middle of the inner cylinder 3 to achieve the fastest reaction in the middle, and then, using the mutual cooperation between the turbine 43, the mounting plate 51 and the No. 1 rod 52, diffuse from the inside to the outside to realize the mixed liquid, propolis and ice cubes The full contact between them improves the mixing efficiency, thereby improving the efficiency of using mixing equipment to manufacture sunscreen.

[0037]During use, at first, put propolis and ice cubes into the inner cylinder 3 from the feed pipe 21, at the same time, the controller controls the forward and reverse motor 41 to rotate in the reverse direction, and the turbine 43 also rotates in the reverse direction. At this time, the turbine 43 cann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com