Basic aluminum sulfate regeneration desulfurization process based on retarded oxidation and multi-field synergistic desorption

A technology for inhibiting oxidation and aluminum sulfate, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problem of increasing the supplementary cost of basic aluminum sulfate, increasing the supplementary cost of basic aluminum sulfate, and reducing the cyclic desulfurization-desorption performance. and other problems, to achieve the effect of realizing the economical supply of aluminum sulfate, promoting the physical gas-liquid mass transfer ability, and enhancing the chemical dissociation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

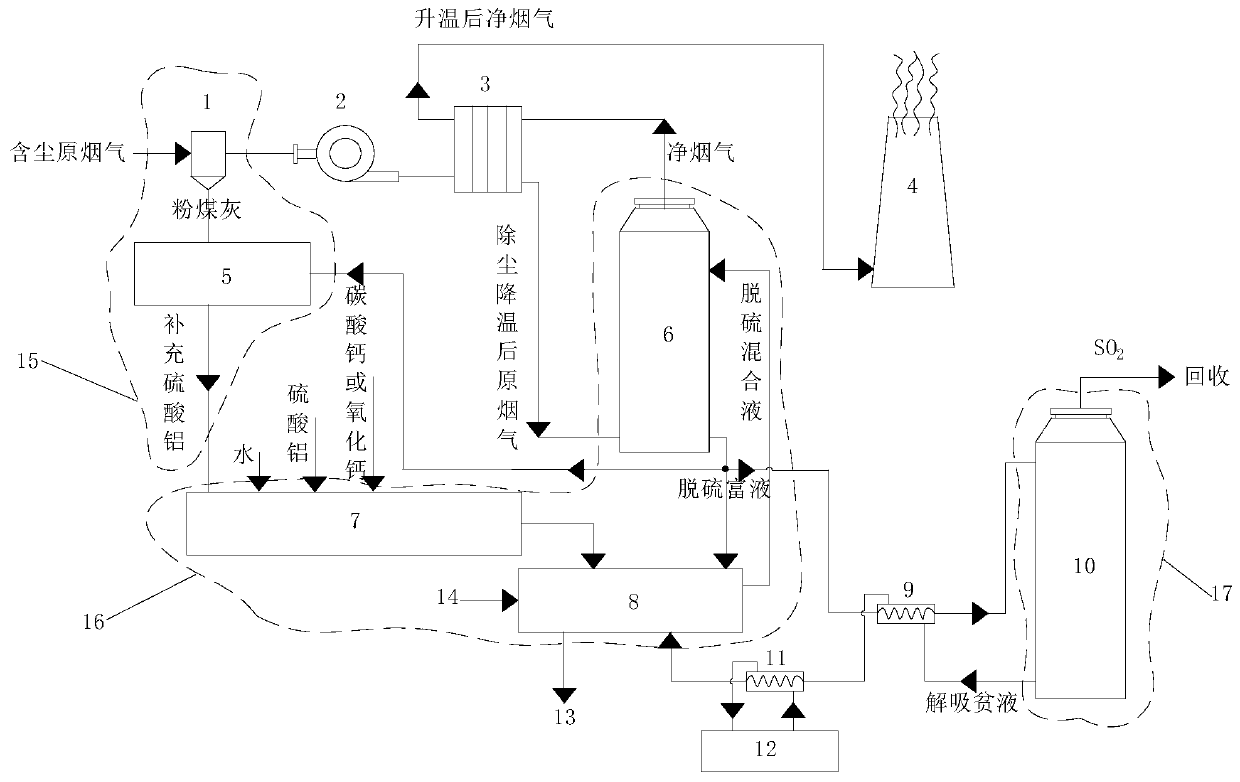

[0044] Based on the basic aluminum sulfate regenerative desulfurization method based on oxidation inhibition and multi-field synergistic desorption, dust-containing raw flue gas is desulfurized through a device including an aluminum loss economic supply module 15, a desulfurization inhibition oxidation module 16, and a multi-field synergistic enhanced desorption module 17;

[0045] The aluminum loss economic replenishment module 15 includes a dust collector 1 and a fly ash soaking pool 5, and the desulfurization suppression oxidation module 16 includes a desulfurization device 6, a basic aluminum sulfate preparation pool 7 and a desulfurization mixed liquid circulation pool 8, and the multi-field synergy The enhanced desorption module 17 includes a desorption device 10;

[0046] The desulfurization process of the dust-containing raw flue gas is as follows: after the dust-containing raw flue gas enters the dust collector 1 for filtering dust, the dust-removed raw flue gas and fl...

Embodiment 2

[0051] Based on the basic aluminum sulfate regenerative desulfurization method based on oxidation inhibition and multi-field synergistic desorption, dust-containing raw flue gas is desulfurized through a device including an aluminum loss economic supply module 15, a desulfurization inhibition oxidation module 16, and a multi-field synergistic enhanced desorption module 17;

[0052] The aluminum loss economic replenishment module 15 includes a dust collector 1 and a fly ash soaking pool 5, and the desulfurization suppression oxidation module 16 includes a desulfurization device 6, a basic aluminum sulfate preparation pool 7 and a desulfurization mixed liquid circulation pool 8, and the multi-field synergy The enhanced desorption module 17 includes a desorption device 10;

[0053] The desulfurization process of the dust-containing raw flue gas is as follows: after the dust-containing raw flue gas enters the dust collector 1 for filtering dust, the dust-removed raw flue gas and fl...

Embodiment 3

[0058] Based on the basic aluminum sulfate regenerative desulfurization method based on oxidation inhibition and multi-field synergistic desorption, dust-containing raw flue gas is desulfurized through a device including an aluminum loss economic supply module 15, a desulfurization inhibition oxidation module 16, and a multi-field synergistic enhanced desorption module 17;

[0059] The aluminum loss economic replenishment module 15 includes a dust collector 1 and a fly ash soaking pool 5, and the desulfurization suppression oxidation module 16 includes a desulfurization device 6, a basic aluminum sulfate preparation pool 7 and a desulfurization mixed liquid circulation pool 8, and the multi-field synergy The enhanced desorption module 17 includes a desorption device 10;

[0060] The desulfurization process of the dust-containing raw flue gas is as follows: after the dust-containing raw flue gas enters the dust collector 1 for filtering dust, the dust-removed raw flue gas and fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com