Mixed refrigerant recovery storage and component adjustment device for FLNG (floating liquefied natural gas)

A technology of mixing refrigerant and adjusting device, applied in refrigeration components, refrigerators, refrigeration and liquefaction, etc., can solve the problems of increased operating cost, loss of mixed refrigerant, incomplete recovery of mixed refrigerant, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

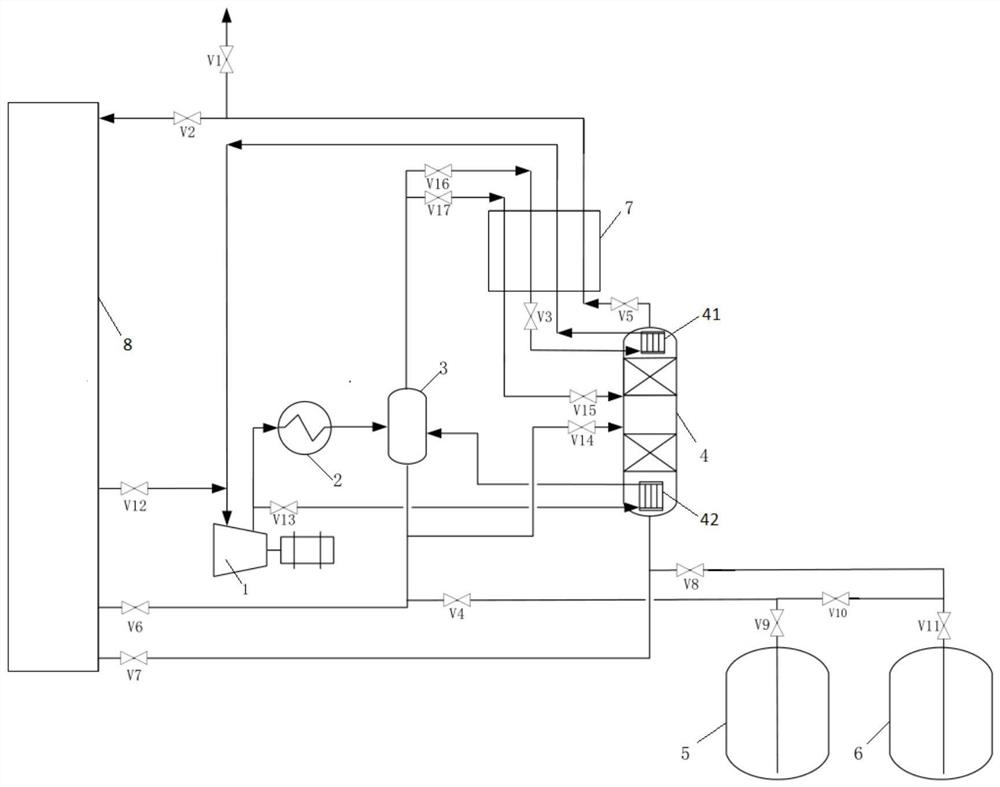

[0021] see figure 1 , a mixed refrigerant recovery storage and component adjustment device, including a compressor 1, the inlet of the compressor is connected to the first mixed refrigerant separation tank in the mixed refrigerant circulation system 8 through a pipeline equipped with a twelfth valve V12, The outlet of the compressor is connected to the cooler 2 through a pipeline, and the cooler 2 is connected to the gas-liquid separator 3 through a pipeline.

[0022] The liquid phase port of the gas-liquid separator is connected to the first storage tank 5 through a pipeline equipped with a fourth valve V4 and a ninth valve V9; the liquid phase port of the gas-liquid separator is connected to the first storage tank 5 through a pipeline equipped with a sixth valve V6 The pipeline is connected to the second mixed refrigerant separation tank in the mixed refrigerant system 8; the liquid phase port of the gas-liquid separator is connected to the feed port in the middle of the sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com