Titanium-based composite catalyst gauze capable of high-effectively degrading formaldehyde and preparation method thereof

A composite catalytic net and catalytic net technology, applied in chemical instruments and methods, separation methods, physical/chemical process catalysts, etc., can solve the problems of low degradation efficiency, low absorption efficiency, difficult formaldehyde degradation, etc., and achieve good mechanical properties, The effect of prolonging the single use time and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

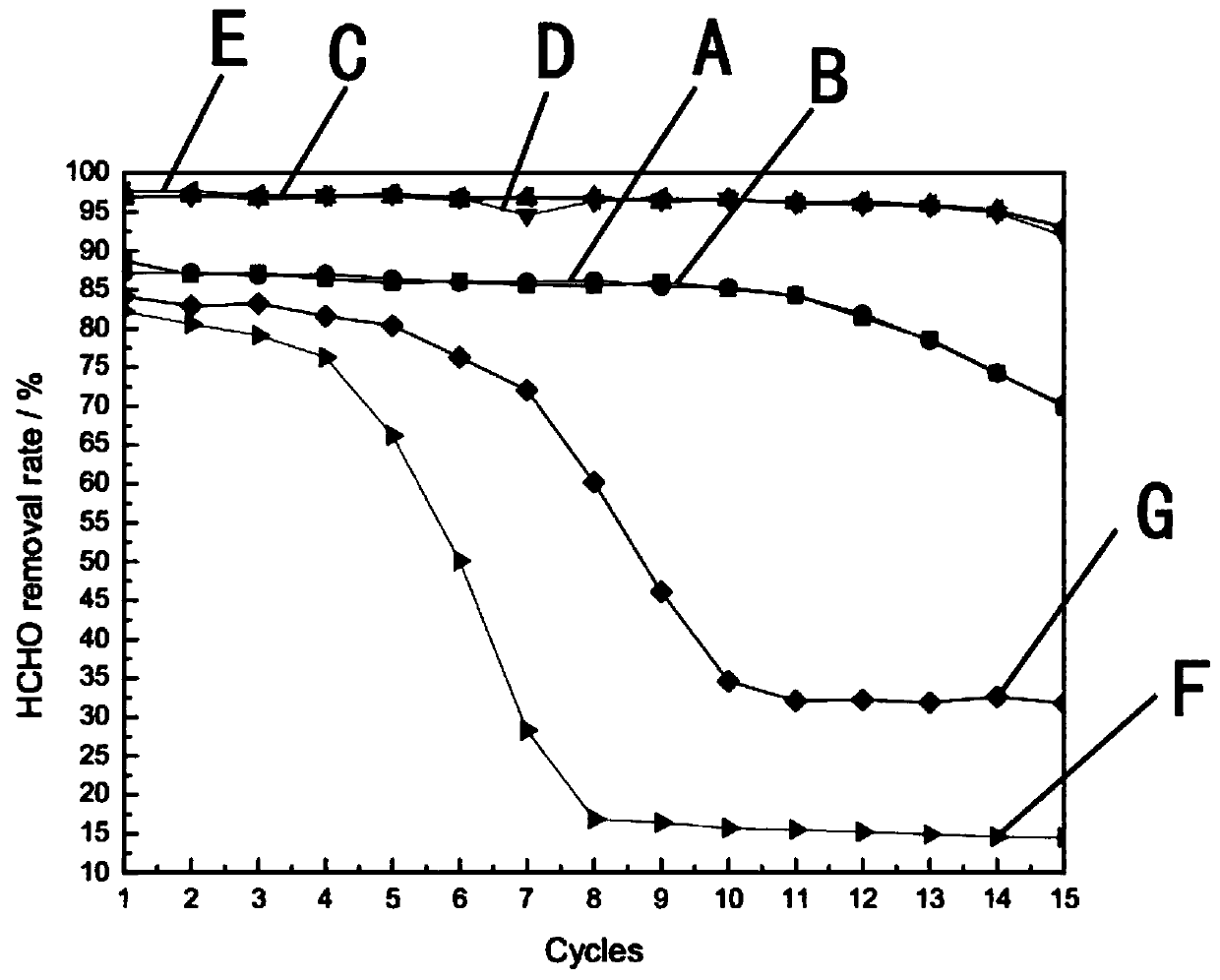

Examples

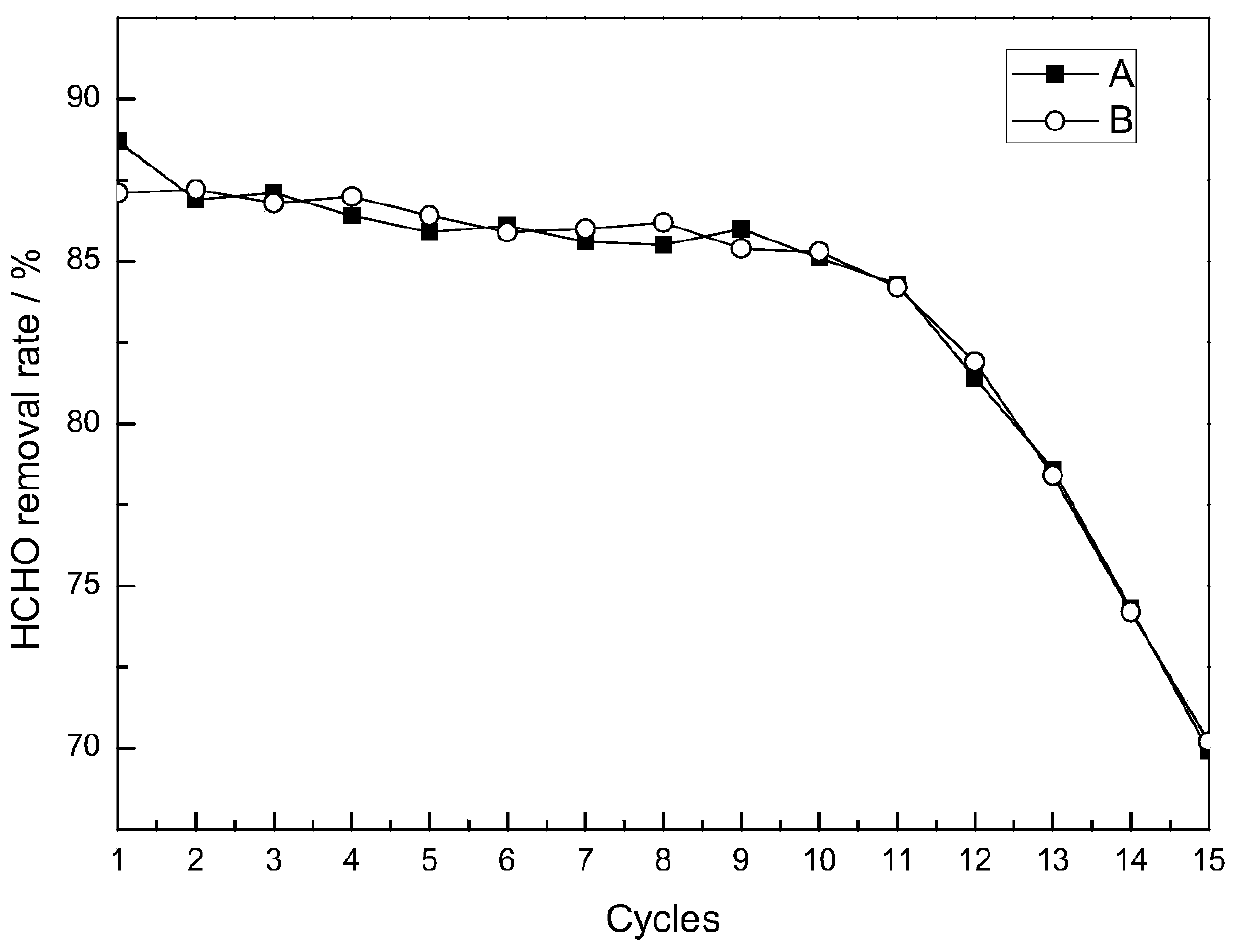

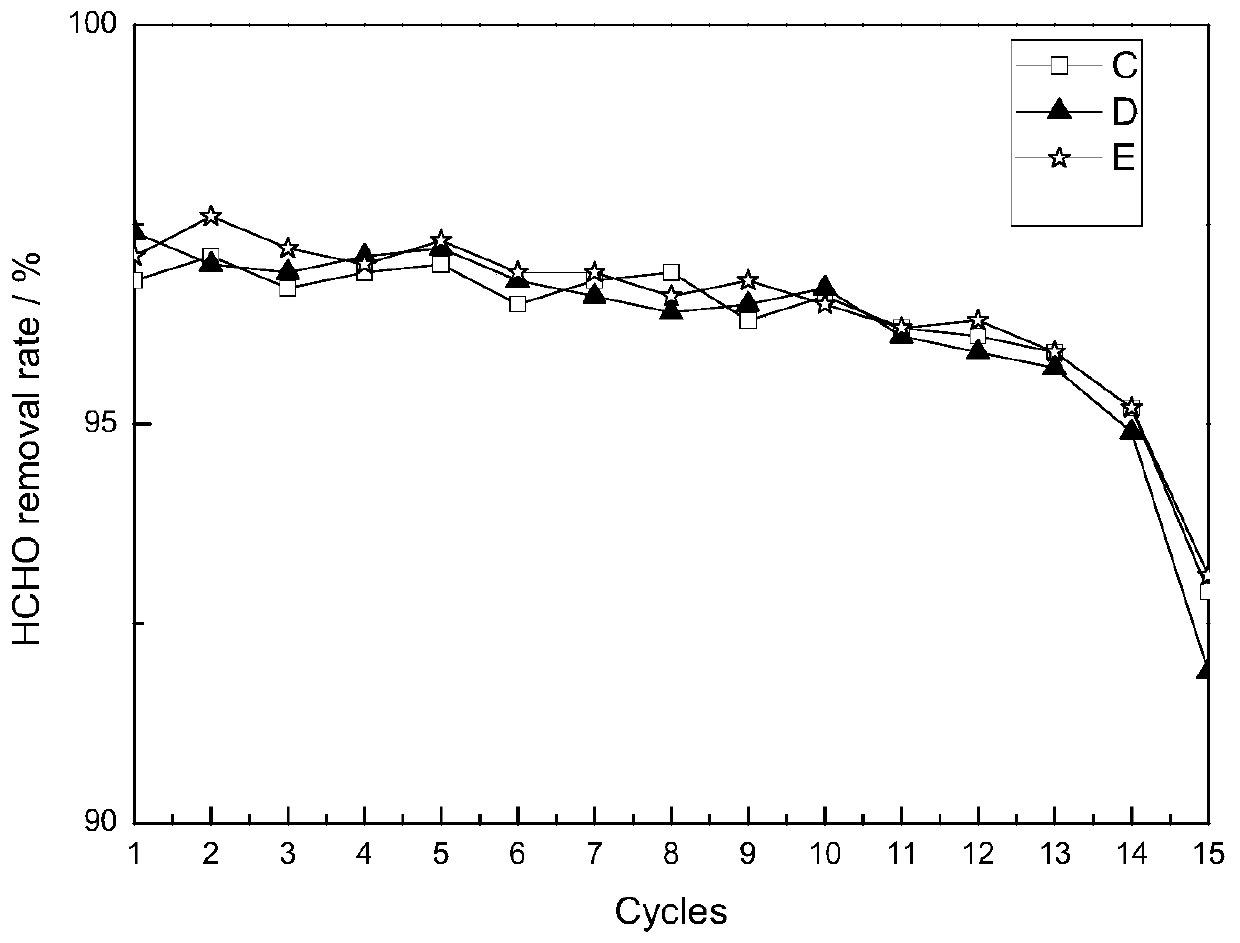

Embodiment 1

[0062] A preparation method of a titanium-based composite catalytic net for efficiently degrading formaldehyde, the method comprising the following steps:

[0063] 1) Use 300-mesh titanium mesh as the substrate for pretreatment, sequentially use mixed acid containing 0.2wt% hydrofluoric acid and 15wt% nitric acid, acetone, ethanol and water to ultrasonically clean the titanium mesh for 5 minutes, and use it as an anode after pretreatment, and place In 0.5wt% hydrofluoric acid aqueous solution, with graphite as the cathode, the titanium mesh was anodized, the anodizing voltage was 20V, the anodizing temperature was 60°C, the anodizing time was 60min, and titanium dioxide nanotubes were grown on the surface of the titanium mesh array, forming a carrier;

[0064] 2) Prepare a pre-solution by dissolving sodium lauryl sulfate in water, adjust the pH of the pre-solution to 3 with glacial acetic acid, preheat to 60°C and keep it for 20 minutes, then add potassium permanganate to prep...

Embodiment 2

[0067] A preparation method of a titanium-based composite catalytic net for efficiently degrading formaldehyde, the method comprising the following steps:

[0068] 1) Use 400-mesh titanium mesh as the substrate for pretreatment, sequentially use mixed acid containing 0.3wt% hydrofluoric acid and 22wt% nitric acid, acetone, ethanol and water to ultrasonically clean the titanium mesh for 5 minutes, and use it as an anode after pretreatment, and place In 1.0wt% hydrofluoric acid aqueous solution, with graphite as the cathode, the titanium mesh was anodized, the anodizing voltage was 60V, the anodizing temperature was 25°C, and the anodizing time was 30min, and titanium dioxide nanotubes were grown on the surface of the titanium mesh array, forming a carrier;

[0069] 2) Dissolve ammonium lauryl sulfate and potassium lauryl sulfate at a molar ratio of 1:1 in water to prepare a pre-solution, and use sulfuric acid to adjust the pH of the pre-solution to 1, preheat to 90°C and keep i...

Embodiment 3

[0072] A preparation method of a titanium-based composite catalytic net for efficiently degrading formaldehyde, the method comprising the following steps:

[0073] 1) Use 300-mesh titanium mesh as the substrate for pretreatment, sequentially use mixed acid containing 0.3wt% hydrofluoric acid and 20wt% nitric acid, acetone, ethanol and water to ultrasonically clean the titanium mesh for 5 minutes, and use it as an anode after pretreatment In a 1.0wt% hydrofluoric acid ethanol solution, graphite is used as a cathode, and the titanium mesh is anodized. The anodizing voltage is 25V, the anodizing temperature is 30°C, and the anodizing time is 180min. Titanium dioxide nanometers are grown on the surface of the titanium mesh. an array of tubes, forming a carrier;

[0074] 2) Prepare a pre-solution by dissolving sodium lauryl sulfate in water, adjust the pH of the pre-solution to 3 with glacial acetic acid, preheat to 65°C and keep it for 15 minutes, then add sodium permanganate and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com