Aluminum-steel composite fastening disc

A securing, aluminum-steel technology, used in non-electric welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of low strength, easy breakage, low density and corrosion resistance, and achieve convenient and fast welding. , Combined with the effect of tight interface and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing an aluminum-steel composite fastening disc, comprising the steps of:

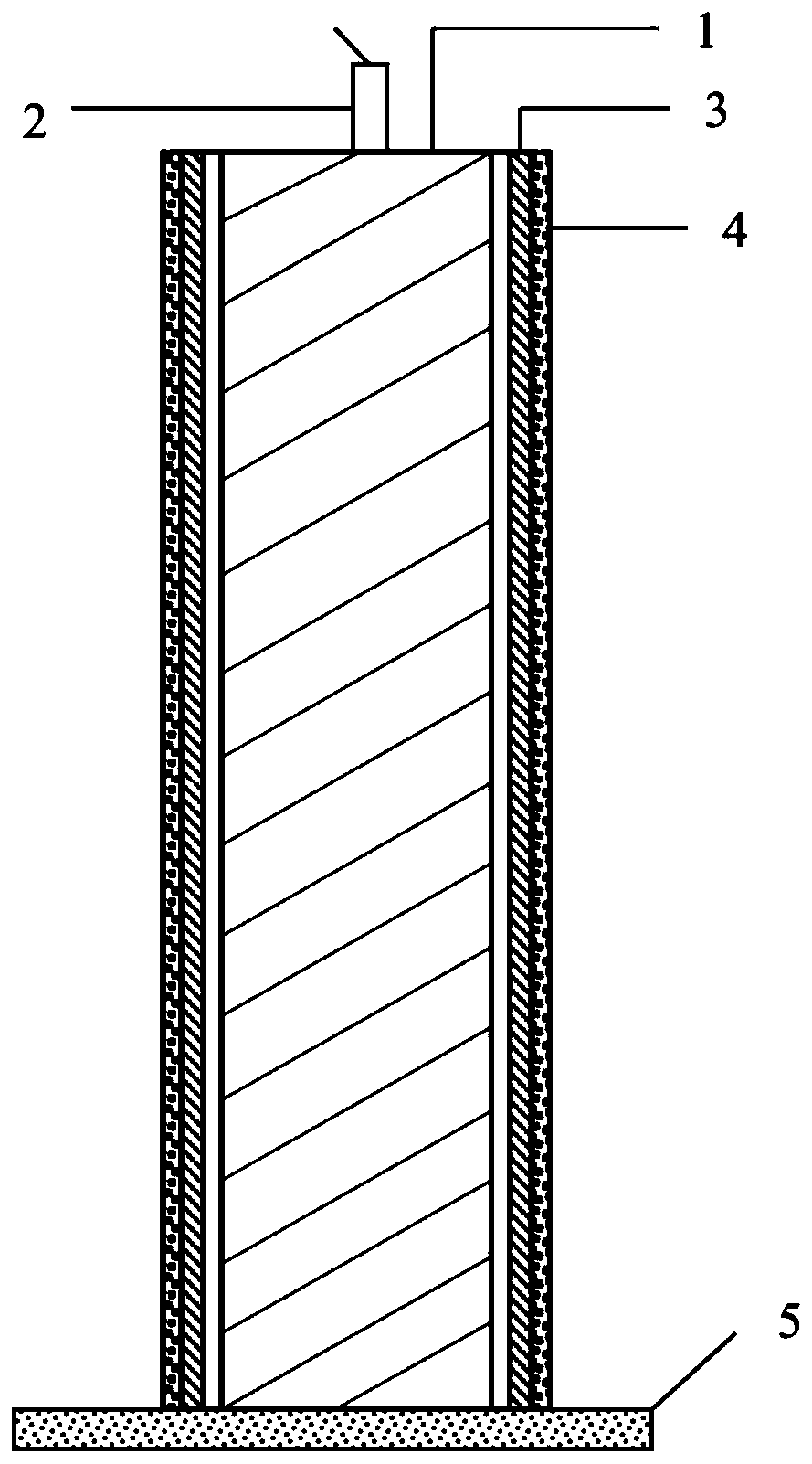

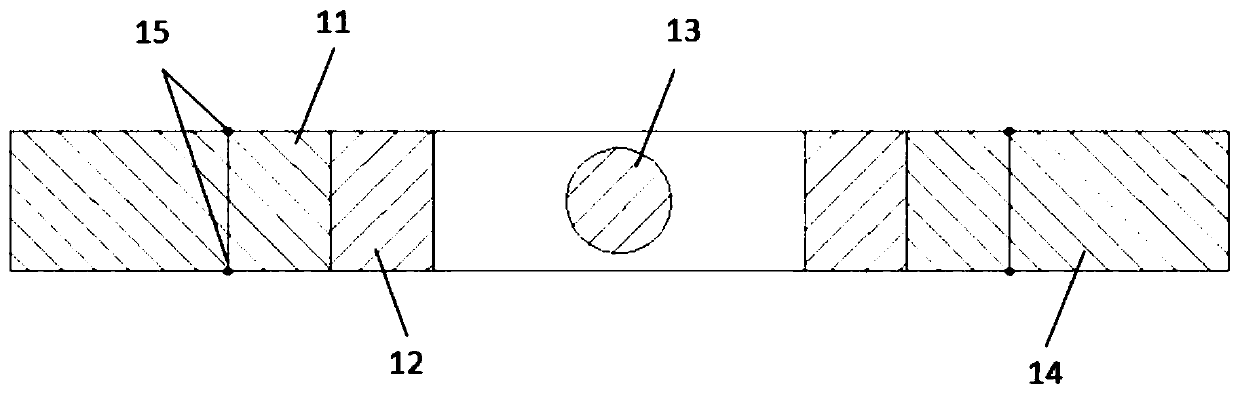

[0041] Choose a stainless steel rod 1 with a length of 1000mm and an outer diameter of 200mm, and brush the outer periphery of the steel rod to remove the oxide layer;

[0042] Select an aluminum tube 3 with a length of 1000 mm and a diameter of 310 mm, and brush the inner wall of the aluminum tube to remove the oxide layer;

[0043] Use industrial alcohol to clean the stainless steel rod 1 and the aluminum tube 3, and after drying, put the aluminum tube 3 on the outside of the stainless steel rod 1, keep the radial distance between the aluminum tube and the stainless steel rod at 5 mm, and place it on the welding platform 5;

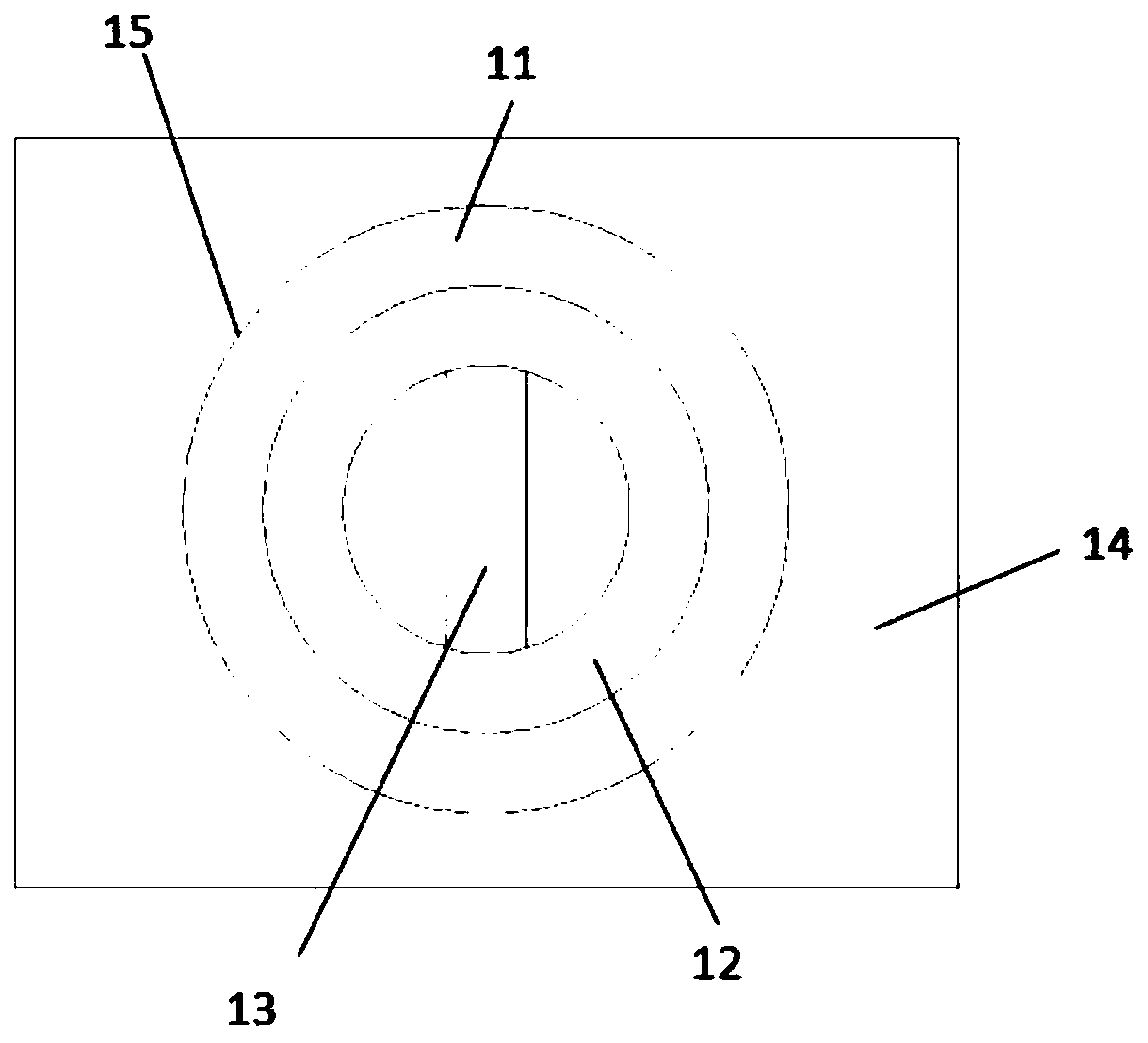

[0044] Place the expanded ammonium nitrate explosives in the PVC explosive frame 4, arrange the explosive frame 4 evenly on the outer surface of the aluminum tube, and the central charge is 50.0mg / mm 2 , gradually decreasing from the center to both side...

Embodiment 2

[0049] A method for preparing an aluminum-steel composite fastening disc, comprising the following steps:

[0050] Choose a stainless steel rod 1 with a length of 1000mm and an outer diameter of 200mm, and brush the outer periphery of the steel rod to remove the oxide layer;

[0051] Choose an aluminum tube 3 with a length of 1000mm and a diameter of 308mm, and brush the inner wall of the aluminum tube to remove the oxide layer;

[0052] Use industrial alcohol to clean the stainless steel rod 1 and the aluminum tube 3, and after drying, put the aluminum tube 3 on the outside of the stainless steel rod 1, keep the radial distance between the aluminum tube and the stainless steel rod at 4 mm, and place it on the welding platform 5;

[0053] Place the expanded ammonium nitrate explosives in the PVC explosive frame 4, arrange the explosive frame 4 evenly on the outer surface of the aluminum tube, and the central charge is 40.0mg / mm 2 , gradually decreasing from the center to both...

Embodiment 3

[0058] A method for preparing an aluminum-steel composite fastening disc, comprising the following steps:

[0059] Choose a stainless steel rod 1 with a length of 1000mm and an outer diameter of 200mm, and brush the outer periphery of the steel rod to remove the oxide layer;

[0060] Choose an aluminum tube 3 with a length of 1000mm and a diameter of 306mm, and brush the inner wall of the aluminum tube to remove the oxide layer;

[0061] Use industrial alcohol to clean the stainless steel rod 1 and the aluminum tube 3, and after drying, put the aluminum tube 3 on the outside of the stainless steel rod 1, keep the radial distance between the aluminum tube and the stainless steel rod at 3 mm, and place it on the welding platform 5;

[0062] Place the expanded ammonium nitrate explosives in the PVC explosive frame 4, arrange the explosive frame 4 evenly on the outer surface of the aluminum tube, and the central charge is 30.0mg / mm 2 , gradually decreasing from the center to both...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com