Biological peptide solid state fermentation method and solid fermentation device for animal feed

A technology of solid fermentation device and animal feed, which is applied in the direction of animal feed, animal feed, bioreactor/fermenter for specific purposes, etc. Can not provide organic trace elements and other problems, to achieve the effect of protecting intestinal health, conducive to processing and production, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

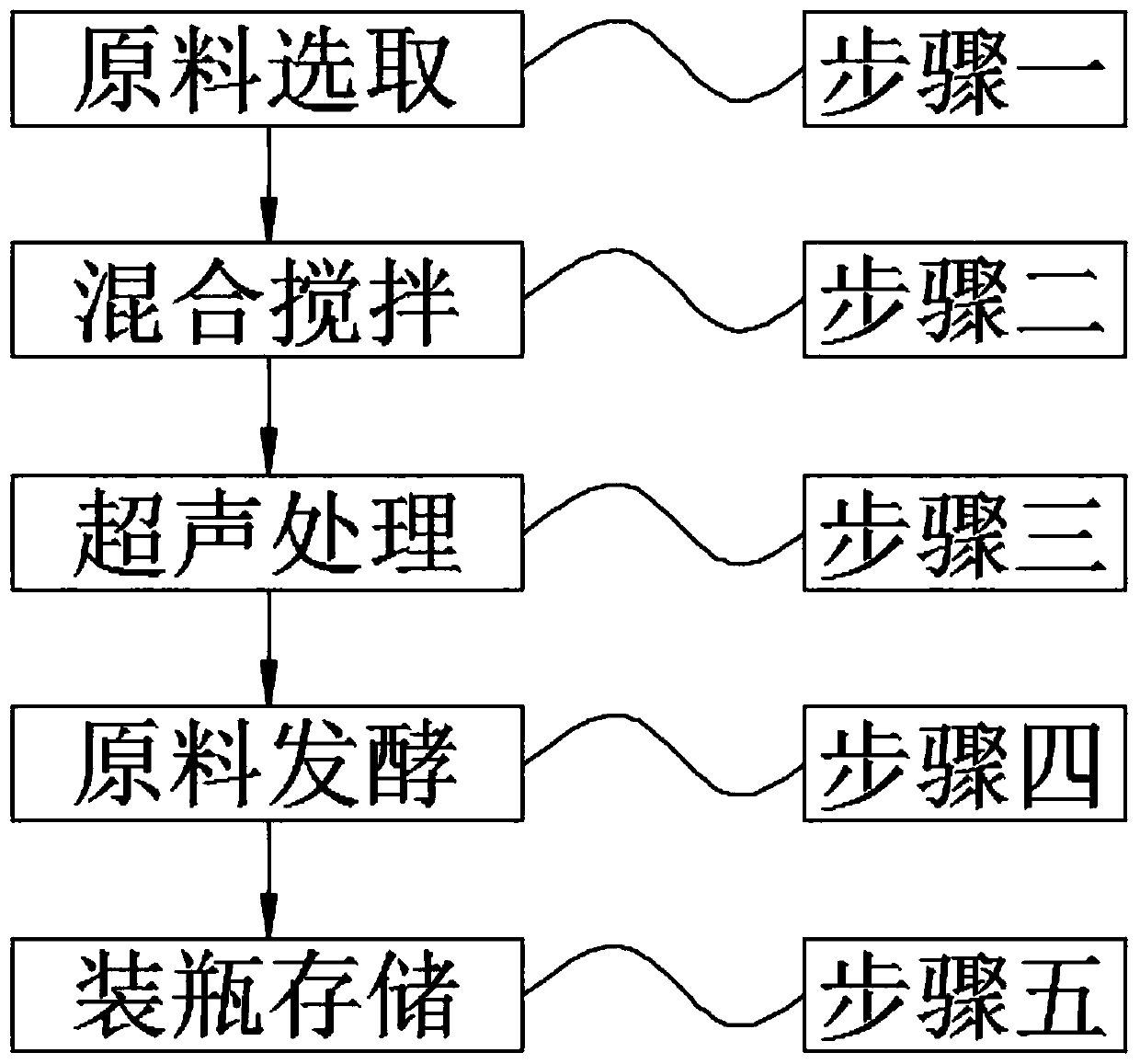

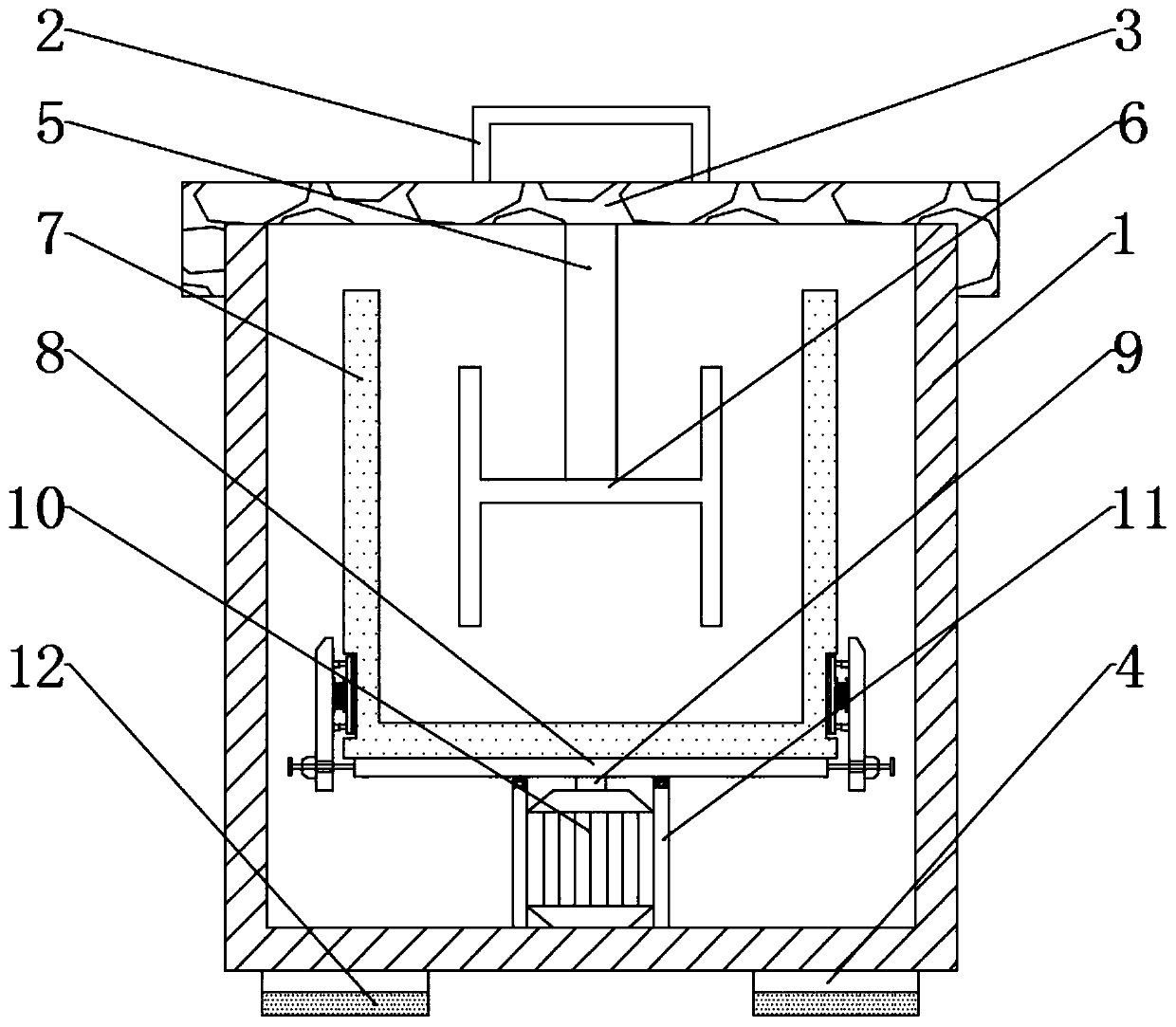

[0038] see Figure 1-5 , the solid-state fermentation method of biological peptides for animal feed provided by the embodiment of the present invention includes the following steps: S1, weighing raw materials; S2, mixing and stirring; S3, ultrasonic treatment; S4, raw material fermentation; S5, bottling and storing;

[0039] The raw materials were weighed according to the following ratios by mass: 16 parts of amino acids, 25 parts of agar, 20 parts of glucose, 10 parts of antioxidants, 4 parts of yeast extract, 10 parts of active protein, 3 parts of seafood, 10 parts of probiotics, 1 part of digestive enzymes and 1 part of polysaccharides;

[0040] Wherein in above-mentioned S2, mixing and stirring comprises the following steps:

[0041] 1) Clean the fermenter, add amino acid and agar, and stir slowly for 1-2 hours;

[0042] 2) Add antioxidants, glucose and yeast extract, raise the temperature to 30-40°C, and stir slowly;

[0043] 3) Crush the seafood, stir evenly, blend in...

Embodiment 2

[0056] Embodiment 2: The biological peptide solid-state fermentation method and device for animal feed provided by the embodiment of the present invention are basically the same as in Embodiment 1, except that:

[0057] S1: Weighing raw materials, according to the following mass ratio: 15 parts of amino acids, 20 parts of agar, 15 parts of glucose, 10 parts of antioxidants, 2 parts of yeast extract, 10 parts of active protein, 1 part of seafood, 5 parts of probiotics, 0.5 parts of digestive enzymes and 0.5 parts of polysaccharides;

Embodiment 3

[0058] Embodiment 3: The biological peptide solid-state fermentation method and device for animal feed provided by the embodiment of the present invention are basically the same as those in Embodiments 1 and 2, except that:

[0059] S1: Weighing of raw materials, according to the following mass ratio: 25 parts of amino acids, 30 parts of agar, 25 parts of glucose, 20 parts of antioxidants, 4 parts of yeast extract, 20 parts of active protein, 2.5 parts of seafood, 7.5 parts of probiotics, 0.8 parts of digestive enzymes and 0.8 parts of polysaccharides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com