Method for accelerating polyvinyl alcohol soluble microneedle forming and instant administration and prepared microneedle

A polyvinyl alcohol and soluble technology, applied in the field of medicine, can solve problems such as restricting the industrialization development of polyvinyl alcohol soluble microneedles, and achieve the effects of easy mass production, simple method and accelerated molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

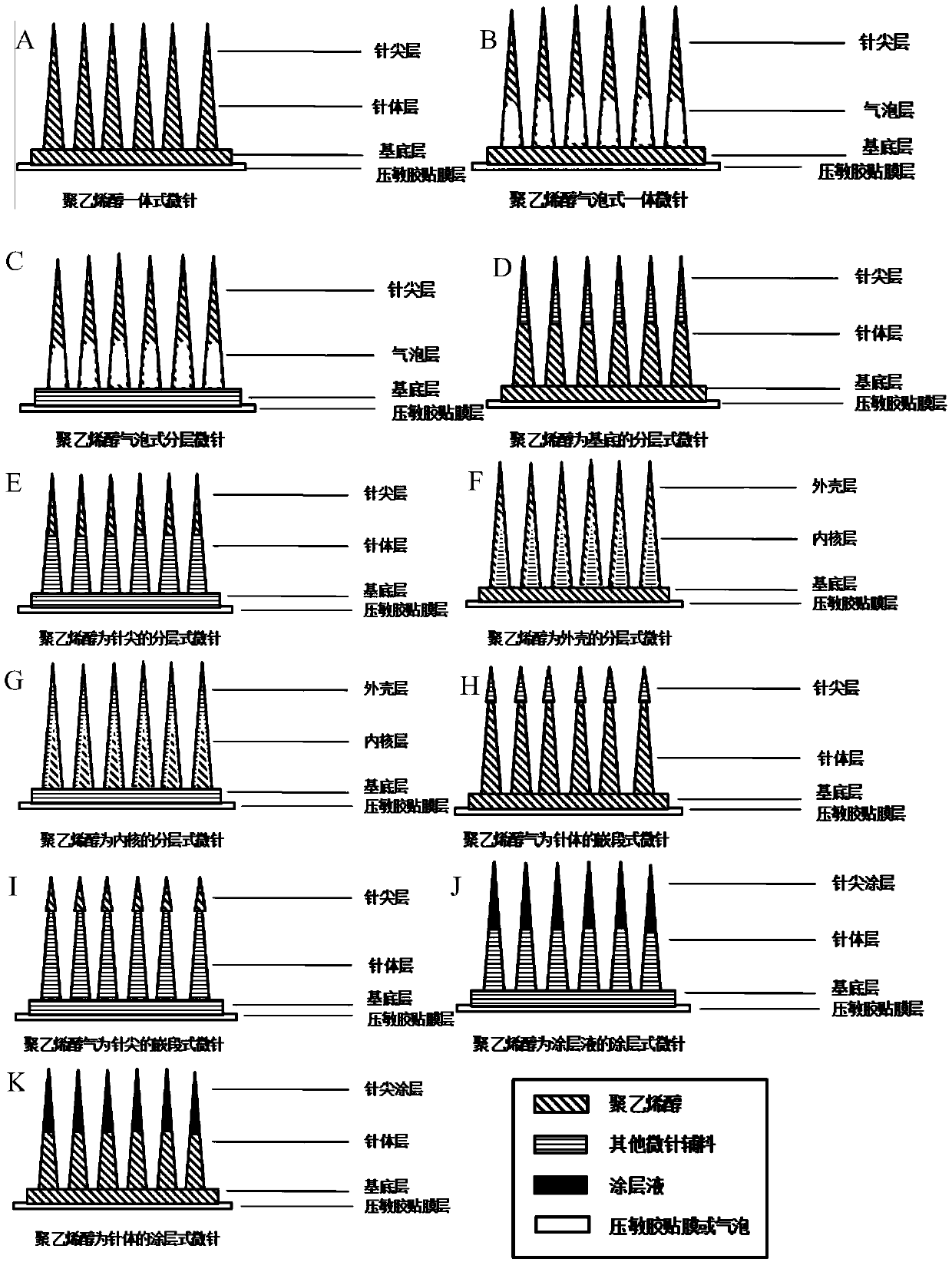

Image

Examples

Embodiment 1

[0051] Example 1 Preparation of polyvinyl alcohol-soluble microneedles containing magnesium chloride

[0052] 1. Use a pipette gun to pipette 6.92mL of ultrapure water into a 50mL centrifuge tube, use an electronic balance to accurately weigh 0.08g of magnesium chloride hexahydrate and add it to the centrifuge tube to dissolve, then weigh 3g of polyvinyl alcohol into the centrifuge tube, and stir Afterwards, heating and dissolving under the condition of 80° C., and removing air bubbles in the solution by centrifugation to obtain a microneedle preparation solution.

[0053] 2. Use a continuous sampling gun to draw 20 microliters of the microneedle solution prepared in step 1 and add it to each unit of the PDMS mold to make it evenly distributed. After adding the sample, vacuumize the solution to fill the microneedles under negative pressure conditions For pinholes, turn on the blowing equipment of the ultra-clean bench to dry the microneedles on the PDMS mold.

[0054] 3. Afte...

Embodiment 4-6

[0065] Example 4-6 Preparation of polyvinyl alcohol-soluble microneedles containing sodium alginate

[0066] According to the preparation method of Example 1, the polyvinyl alcohol soluble microneedles containing sodium alginate in Examples 4-6 were respectively prepared with reference to the corresponding prescriptions in Table 2, and the flatness, ductility, and drying time of the microneedles were evaluated. The results are shown in the table 2.

[0067] Table 2 Example 4-6 Polyvinyl Alcohol Soluble Microneedle Prescription and Acupuncture Effect

[0068]

Embodiment 7-15

[0069] Example 7-15 Preparation of polyvinyl alcohol integrated microneedles containing magnesium chloride, zinc chloride, and calcium chloride

[0070] According to the preparation method of Example 1, with reference to the corresponding prescriptions in Table 3, the polyvinyl alcohol integrated microneedles of Examples 7-15 containing magnesium chloride, zinc chloride, and calcium chloride were respectively prepared, and the flatness, ductility, and drying time of the microneedles were evaluated. For evaluation, the results are shown in Table 3.

[0071] Table 3 Example 7-15 Polyvinyl Alcohol Soluble Microneedle Prescription and Acupuncture Effect

[0072]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com