High-corrosion-resistance submicron composite material and applications thereof

A composite material, sub-micron technology, applied in the field of building materials, can solve the problems of large water demand, easy agglomeration, expensive nano materials, etc., to achieve the effect of small water demand, low compressive strength loss rate, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Preparation of high-corrosion submicron composite materials:

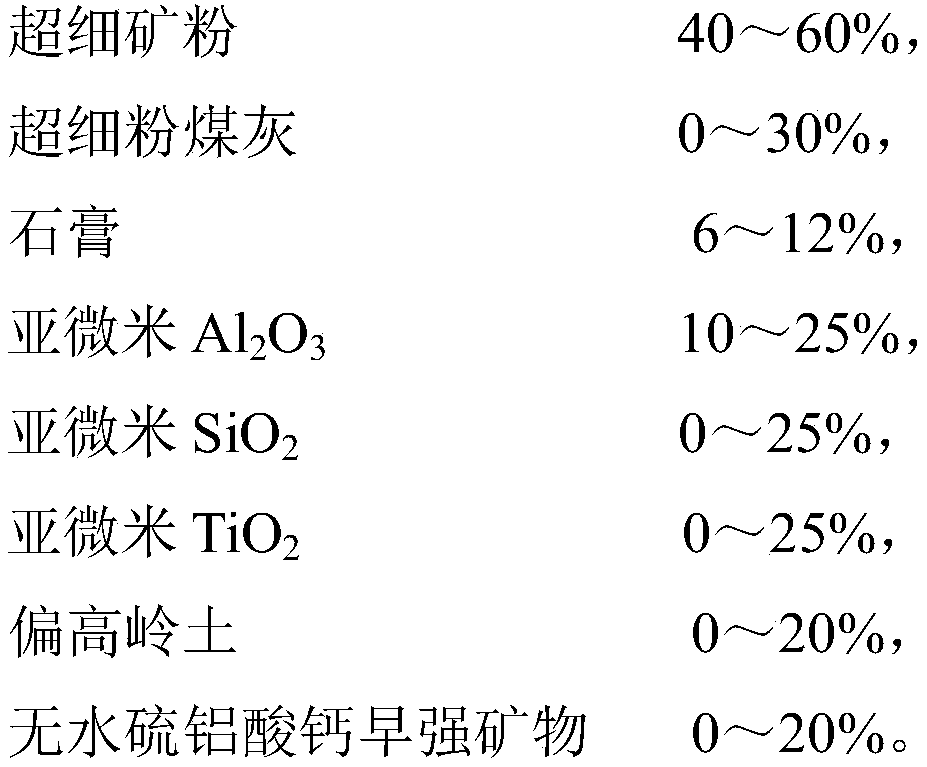

[0040] Weigh the raw materials according to the following mass percentages and components, and fully mix them; the raw material components and quantities are as follows:

[0041] 40 parts of ultrafine mineral powder, 10 parts of ultrafine fly ash, 10 parts of gypsum, 500nm Al 2 o 3 20 parts, metakaolin 10 parts, anhydrous calcium sulfoaluminate early strength mineral 10 parts.

[0042] 2. Cement sample preparation:

[0043] Take the high-corrosion-resistant submicron composite material prepared in step 1, mix it into marine POP32.5 cement at a cement mass percentage of 3%, and mix thoroughly to make an improved cement sample.

[0044] 3. Physical performance test of cement:

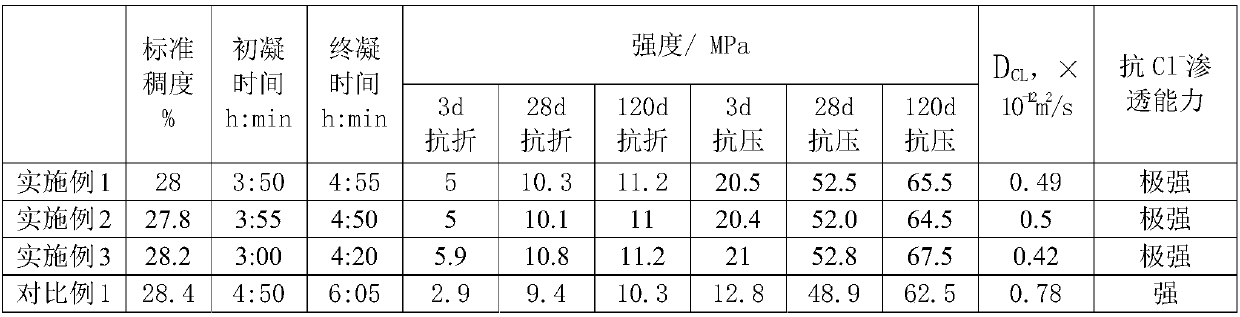

[0045] The cement samples prepared by the above method are tested according to GB / T 17671 "Cement Mortar Strength Test Method (ISO Method)" and GB / T 1346 "Cement Standard Consistency Water Consumption, Setting Time and Stability...

Embodiment 2

[0051] The same as in Example 1, the change is: when preparing the cement sample, the amount of the high-corrosion-resistant submicron composite material is adjusted to 2% by mass.

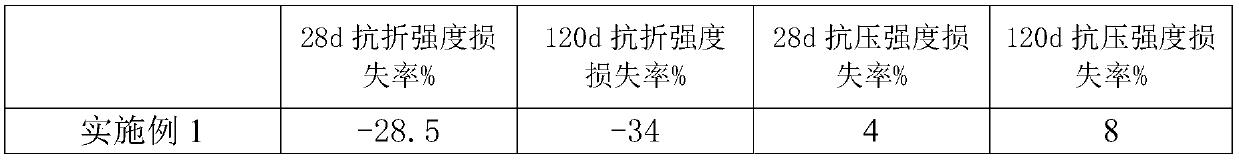

[0052] The performance test results are shown in Table 1-6.

Embodiment 3

[0054] Same as in Example 1, the change is: when preparing the cement sample, the amount of the high-corrosion-resistant submicron composite material is adjusted to 5% by mass.

[0055] The performance test results are shown in Table 1-6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com