Urea formaldehyde-ammonium nitrate liquid fertilizer as well as preparation method and application thereof

A technology of liquid fertilizer and urea-formaldehyde, applied in ammonium nitrate fertilizer, application, liquid fertilizer, etc., can solve the problems of high soil requirements and cost, short fertilizer effect, easy crystallization, etc., to extend the fertilizer effect cycle, improve utilization rate, and meet nutritional needs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

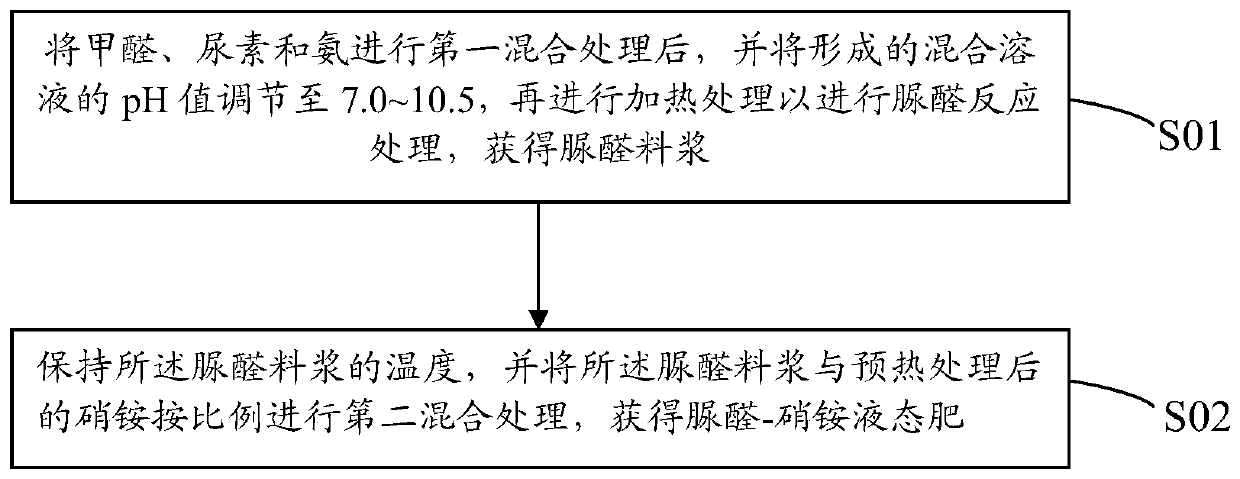

[0029] On the other hand, on the basis of the urea-formaldehyde-ammonium nitrate liquid fertilizer described above, the embodiment of the present invention also provides a preparation method of the urea-formaldehyde-ammonium nitrate liquid fertilizer. The preparation method technology of described urea-formaldehyde-ammonium nitrate liquid fertilizer is as figure 1 As shown, it includes the following steps:

[0030] S01: After the first mixing treatment of formaldehyde, urea and ammonia, the pH value of the formed mixed solution is adjusted to 7.0-10.5, and then heat treatment is performed to perform urea-formaldehyde reaction treatment to obtain urea-formaldehyde slurry;

[0031] S02: maintaining the temperature of the urea-formaldehyde slurry, and performing a second mixing treatment on the urea-formaldehyde slurry and the preheated ammonium nitrate in proportion to obtain a urea-formaldehyde-ammonium nitrate liquid fertilizer.

[0032] Wherein, the formaldehyde, urea and am...

Embodiment 1

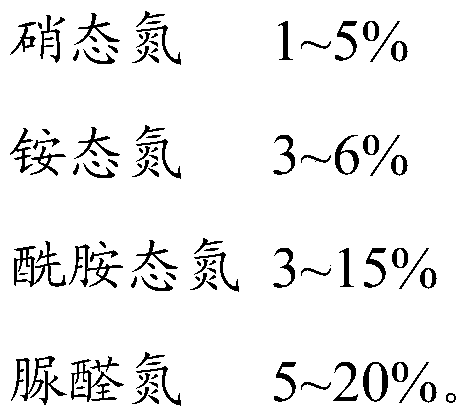

[0054] The embodiment of the present invention provides a urea-formaldehyde-ammonium nitrate liquid fertilizer and a preparation method thereof. Described urea formaldehyde-ammonium nitrate liquid fertilizer comprises water, with described urea formaldehyde-ammonium nitrate liquid fertilizer total mass concentration being 100%, it also comprises the composition of following mass percentage:

[0055]

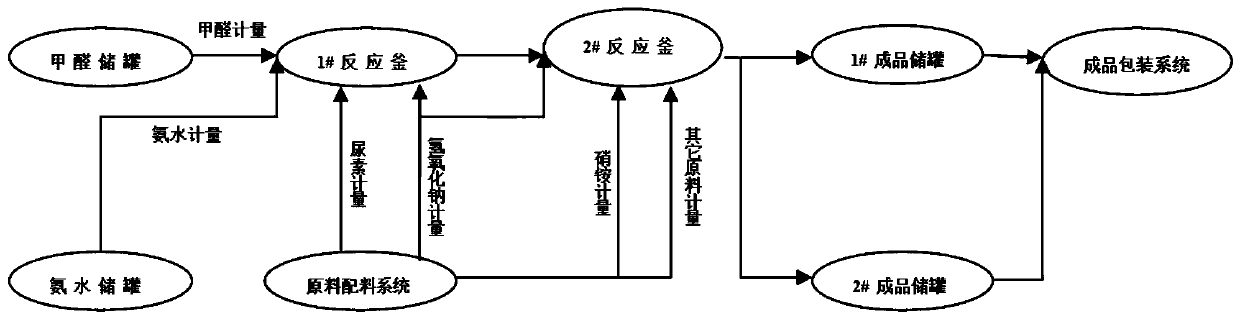

[0056] The preparation method of described urea formaldehyde-ammonium nitrate liquid fertilizer is as figure 1 with figure 2 As shown, it specifically includes the following steps:

[0057] S11: Add formaldehyde solution, small granule urea, and liquid ammonia to the 1# reactor at a molar ratio of 1:0.5~5:0.1~1, adjust the pH value to 7.0~10.5 with an appropriate amount of NaOH, and adjust the heating and heat preservation device of the reactor Keep the temperature of the 1# reactor at 60-95°C, and continue to react for 60 minutes under the constant stirring of the agitator...

Embodiment 2

[0063] The embodiment of the present invention provides a urea-formaldehyde-ammonium nitrate liquid fertilizer and a preparation method thereof. Described urea-formaldehyde-ammonium nitrate liquid fertilizer comprises water, and with described urea-formaldehyde-ammonium nitrate liquid fertilizer total concentration being 100%, it also comprises the composition of following percentage:

[0064]

[0065] The preparation method of described urea formaldehyde-ammonium nitrate liquid fertilizer is as figure 1 with figure 2 As shown, it specifically includes the following steps:

[0066] S11: Add formaldehyde solution, small granule urea, and liquid ammonia to the 1# reactor at a molar ratio of 1:0.5~5:0.1~1, adjust the pH value to 7.0~10.5 with an appropriate amount of NaOH, and adjust the heating and heat preservation device of the reactor Keep the temperature of the 1# reactor at 60-95°C, and continue to react for 50 minutes under the constant stirring of the agitator;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com