Electrostatic chuck of non-sintered aluminum nitride

An electrostatic chuck and aluminum nitride technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as difficult sintering and poor performance of dielectric layer materials, and achieve low porosity, anti-oxidation, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

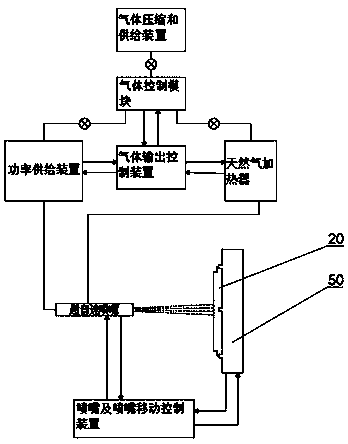

[0023] Hereinafter, the non-sintered aluminum nitride electrostatic chuck of the present invention will be described in detail with reference to the drawings.

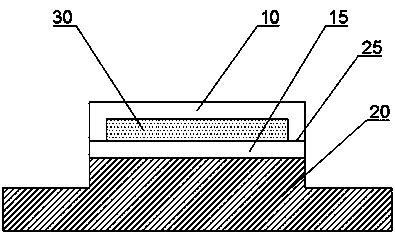

[0024] As a preferred embodiment of the present invention, the non-sintered aluminum nitride (AlN) electrostatic chuck of the present invention includes a substrate 20 , an insulator 15 , an electrode 30 and a dielectric 10 from bottom to top.

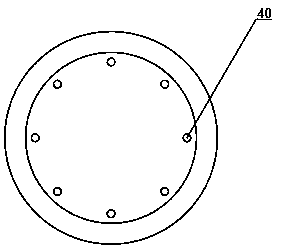

[0025] figure 1 with figure 2 They are respectively a cross-sectional view and a plan view of an implementation example of the non-sintered aluminum nitride (AlN) electrostatic chuck of the present invention.

[0026] In the sinterless aluminum nitride (AlN) electrostatic chuck of the present invention, the coating of aluminum nitride can be formed by various coating methods.

[0027] In particular, the coating of the present invention can be formed by any method such as vapor deposition, hot spray or low-temperature high-speed spray. That is to say, the above-mentioned coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com