High-performance OLED light emitting device

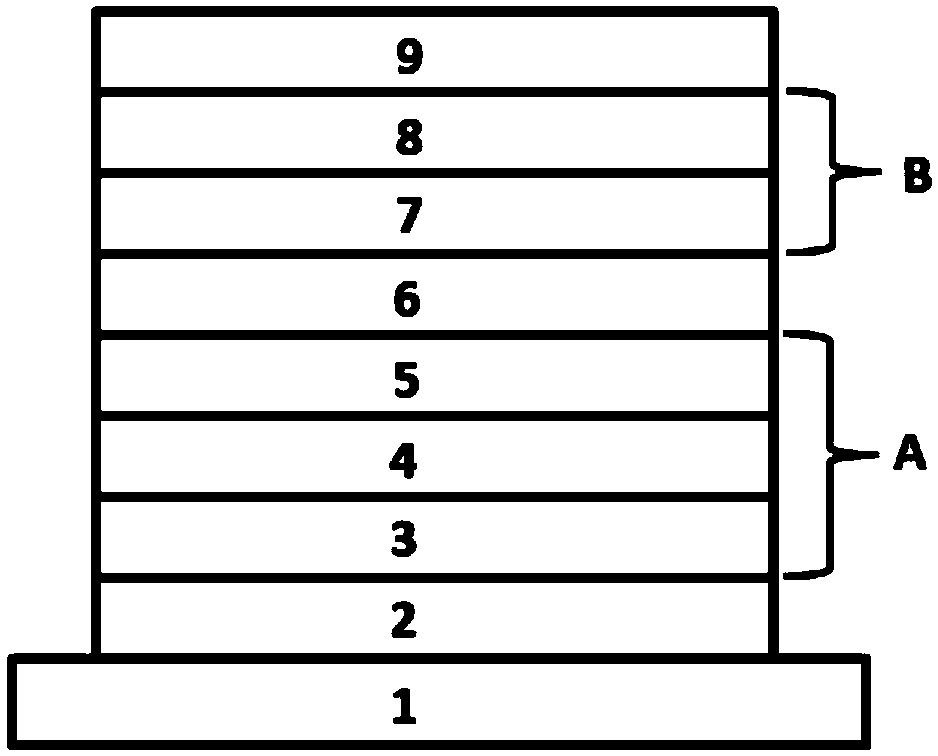

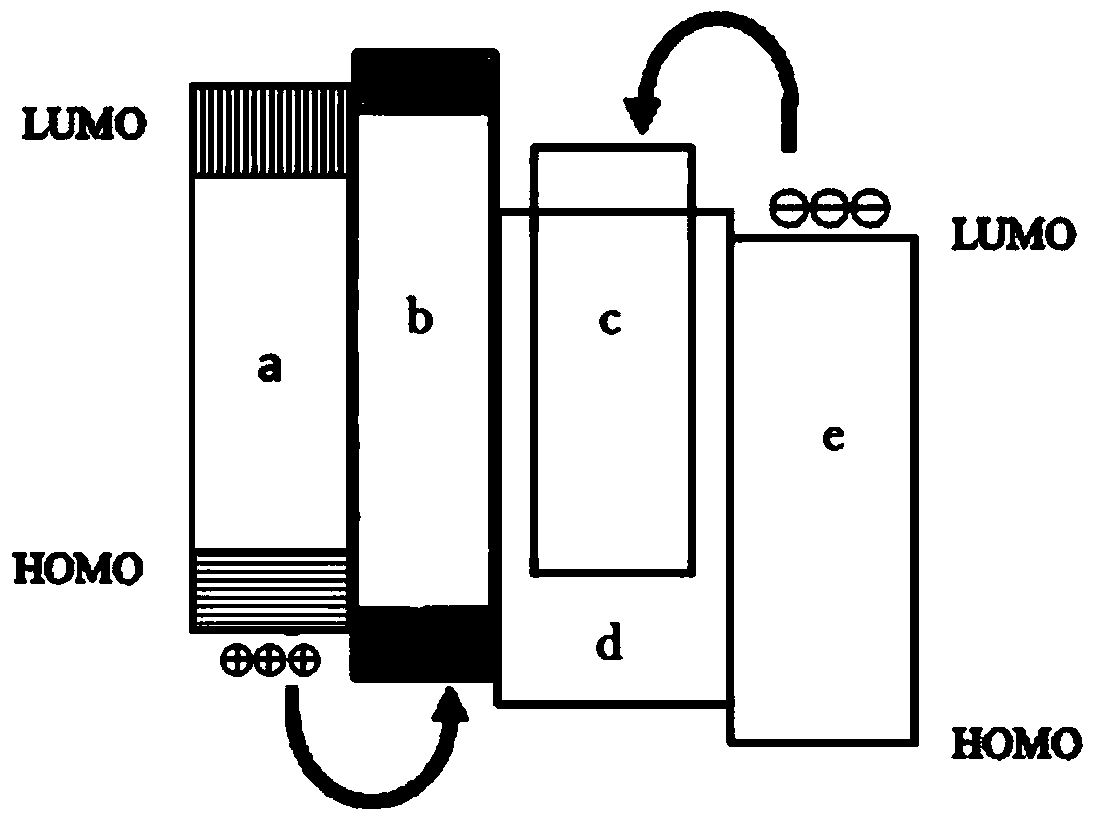

A technology of electroluminescent devices and light-emitting layers, which is applied in the field of OLED light-emitting devices, and can solve problems such as affecting the life of OLED devices, large HOMO energy level difference, and hindering effective hole injection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

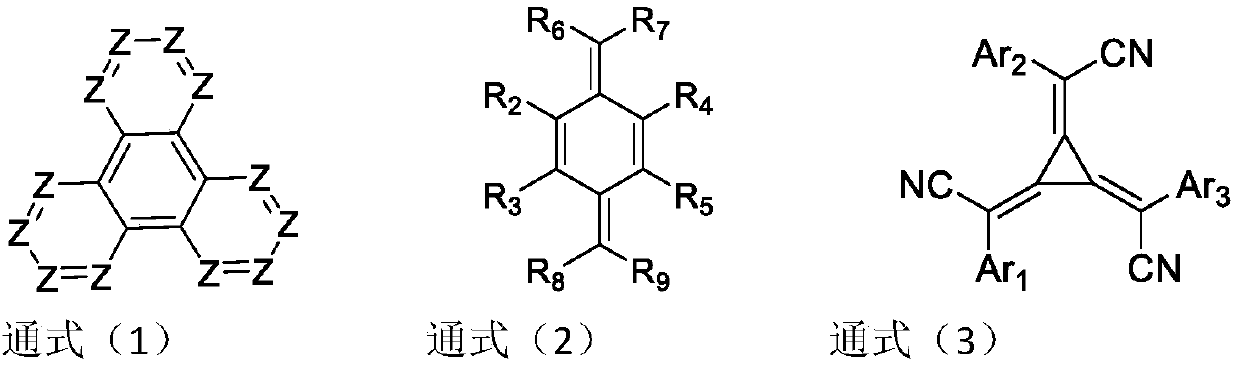

Method used

Image

Examples

Embodiment 1

[0075] Embodiment 1 prepares compound HI-3

[0076]

[0077] Under nitrogen atmosphere, add 0.01mol raw material A1, 0.012mol raw material B1, 0.02mol sodium tert-butoxide, 1×10 -4 mol Pd 2 (dba) 3 and 1×10 -4 mol of tri-tert-butylphosphine, then add 150ml of toluene to dissolve it, heat to 100°C, reflux for 24 hours, observe the reaction by TLC until the reaction is complete. Naturally cooled to room temperature, filtered, and the filtrate was rotary evaporated until there was no fraction. The obtained substance was purified by a silica gel column (the volume ratio of petroleum ether and dichloromethane was 2:1 as eluent) to obtain the target product with a purity of 99.0% and a yield of 66.2%.

[0078] Elemental analysis structure (molecular formula C 54 h 37 N): theoretical value, C, 92.67; H, 5.33; N, 2.00; test value: C, 92.66; H, 5.35; N, 2.01. ESI-MS(m / z)(M + ): The theoretical value is 699.29, and the measured value is 699.50.

Embodiment 2

[0079] Embodiment 2 prepares compound HI-8

[0080]

[0081] According to the synthetic method of compound HI-3, the difference is that raw material A1 is replaced by raw material A2, raw material B1 is replaced by raw material B2, the purity of the obtained target product is 99.91%, and the yield is 73.7%.

[0082] Elemental analysis structure (molecular formula C 48 h 12 D. 21 N): theoretical value, C, 89.39; H, 8.43; N, 2.17; tested value: C, 89.37; H, 8.45; N, 2.19. ESI-MS(m / z)(M + ): The theoretical value is 644.39, and the measured value is 644.59.

Embodiment 3

[0083] Embodiment 3 prepares compound HI-16

[0084]

[0085] It was prepared according to the synthetic method of compound HI-3, except that raw material A3 was used instead of raw material A1, and raw material B3 was used instead of raw material B1. The purity of the obtained target product was 99.84%, and the yield was 70.1%.

[0086] Elemental analysis structure (molecular formula C 60 h 42 N 2 ): theoretical value, C, 91.11; H, 5.35; N, 3.54; test value: C, 91.13; H, 5.36; N, 3.54. ESI-MS(m / z)(M + ): The theoretical value is 790.33, and the measured value is 790.57.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com