Preparation method of flexible low-voltage composite polymer heating film

A composite polymer and low-voltage technology, applied in the direction of electric heating devices, ohmic resistance heating, ohmic resistance heating parts, etc., can solve the unfavorable safety and portability requirements of heating film, uneven heating density, dry skin and other problems. Achieve the effect of easy to carry out, reasonable size and pattern, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

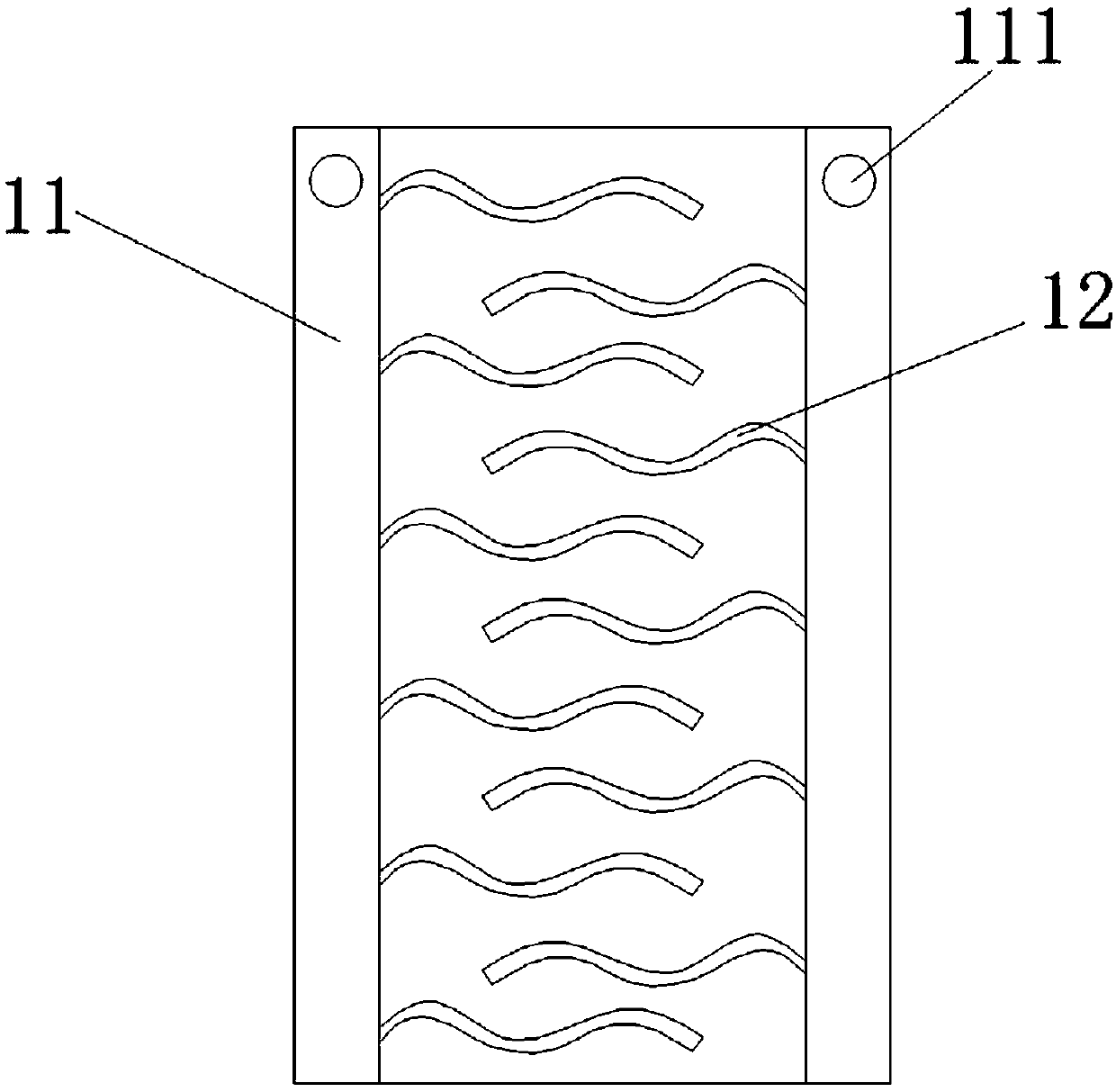

Image

Examples

Embodiment 1

[0027] A method for preparing a flexible low-voltage composite polymer heating film, comprising: adjusting the temperature of an open mill to 160° C., adjusting the roller distance of the open mill to 0.5 mm, and masticating a thermoplastic elastomer on the open mill to a transparent state. Adjust the temperature of the internal mixer to 160°C, mix the masticated thermoplastic elastomer, half of the uniformly mixed solid powder, high flow agent and anti-aging agent through the internal mixer, and add the other half after 5 minutes and mix well The solid powder and base oil banburying for 10min. Solid powders include conductive carbon black, graphene and natural graphite. The mixed materials are pulverized by internal mixer, put into extruder and extruded. Solid powders include conductive carbon black, graphene and natural graphite. The above reaction components include by weight percentage: 65% thermoplastic elastomer, 10% conductive carbon black, 10% graphene, 6% natural gr...

Embodiment 2

[0030]A method for preparing a flexible low-voltage composite polymer heating film, comprising: adjusting the temperature of an open mill to 160° C., adjusting the roller distance of the open mill to 0.5 mm, and masticating a thermoplastic elastomer on the open mill to a transparent state. Adjust the temperature of the internal mixer to 180°C, mix the masticated thermoplastic elastomer, half of the uniformly mixed solid powder, high flow agent and anti-aging agent through the internal mixer, and add the other half after 5 minutes and mix well The solid powder and base oil banburying for 10min. The mixed materials are pulverized by internal mixer, put into extruder and extruded. Solid powders include conductive carbon black, graphene and natural graphite. The above reaction components include by weight percentage: 65% thermoplastic elastomer, 15% conductive carbon black, 6% graphene, 8% natural graphite, 3% anti-aging agent, 3% base oil, and 3% high flow agent. In this embod...

Embodiment 3

[0033] A method for preparing a flexible low-voltage composite polymer heating film, comprising: adjusting the temperature of an open mill to 160° C., adjusting the roller distance of the open mill to 0.5 mm, and masticating a thermoplastic elastomer on the open mill to a transparent state. Adjust the temperature of the internal mixer to 170°C, mix the masticated thermoplastic elastomer, half of the uniformly mixed solid powder, high flow agent and anti-aging agent through the internal mixer, and add the other half after 5 minutes and mix well The solid powder and base oil banburying for 10min. The mixed materials are pulverized by internal mixer, put into extruder and extruded. Solid powders include conductive carbon black, graphene and natural graphite. The above reaction components include by weight percentage: 65% thermoplastic elastomer, 12% conductive carbon black, 8% graphene, 5% natural graphite, 3% anti-aging agent, 3% base oil, and 3% high flow agent. In this embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com