Extractant functionalized magnetic nano adsorption material as well as preparation method and application thereof

A technology of magnetic nanometers and adsorption materials, applied in chemical instruments and methods, selective adsorption, inorganic chemistry, etc., can solve the problems of difficult reactions and side reactions, and overcome the difficulties of surface modification, less side reactions, and produce high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

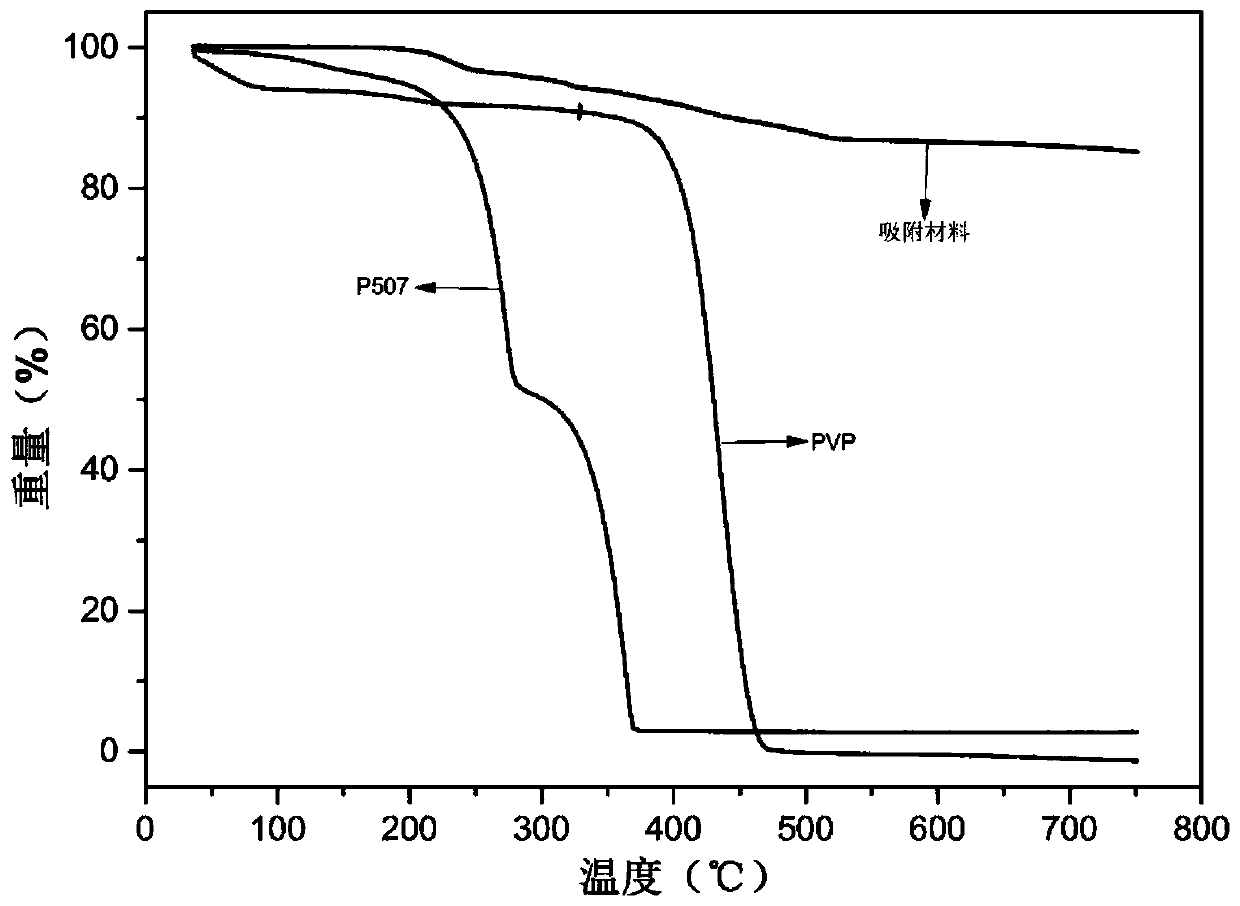

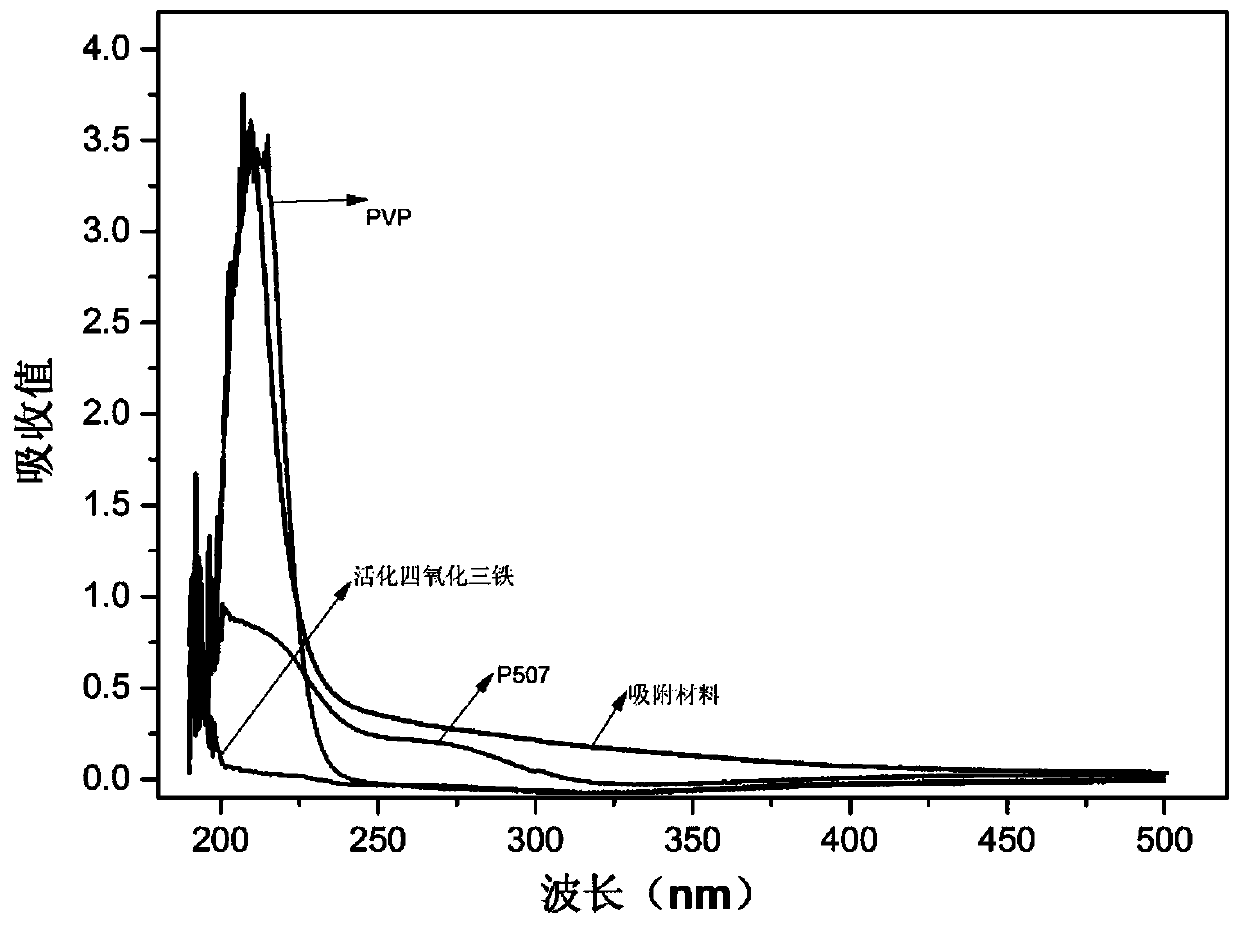

[0038] This specific embodiment is to prepare the extractant functionalized magnetic nano-adsorption material, and the specific process is:

[0039] (1) Accurately weigh 5g of nano-iron ferric oxide, place it in 50ml of hydrochloric acid solution with pH=4, stir ultrasonically for 10 minutes, discard the supernatant after standing for 15 minutes, and dry at 105°C to obtain activated nano-ferric oxide. Ferric oxide.

[0040] (2) Accurately weigh 0.3g of polyvinylpyrrolidone (PVP) and dissolve it in 4ml of ethanol solution, then add 0.2g of 2-ethylhexylphosphonic acid mono(2-ethylhexyl) ester (P507), 0.5 g of the above-mentioned activated ferric iron tetroxide was stirred thoroughly and ultrasonically treated to obtain a mixed system.

[0041] (3) The mixing system in (2) above was placed in a polytetrafluoroethylene-lined reactor, and reacted at a constant temperature of 180° C. for 300 minutes.

[0042] (4) Put the mixed system in (3) above into a beaker, dry it at 85° C., was...

Embodiment 2

[0046] This specific embodiment is also for preparing extractant functionalized magnetic nano-adsorption material, and the specific process is:

[0047] (1) Accurately weigh 5g of nano-iron ferric oxide, place it in 50ml of nitric acid solution with pH=5, stir it ultrasonically for 10 minutes, discard the supernatant after standing for 15 minutes, and dry at 105°C to obtain activated nano-ferric oxide. Ferric oxide.

[0048] (2) Accurately weigh 0.3g of polyvinylpyrrolidone (PVP) and dissolve it in 4ml of ethanol solution, then add 0.1g of 2-ethylhexylphosphonic acid mono(2-ethylhexyl) ester (P507), 0.1 g of bis(2,4,4'-trimethylpentyl) phosphonate (C272), 0.5 g of the above-mentioned activated ferric oxide.

[0049] (3) The mixing system in (2) above was placed in a polytetrafluoroethylene-lined reactor, and reacted at a constant temperature of 120°C for 250 minutes.

[0050] (4) Put the mixed system in (3) above into a beaker, dry it at 105° C., wash it several times with d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com