Cutting machining robot static error compensation and dynamic stiffness model correction method

A static error and cutting processing technology, which is applied in the direction of manipulators, manufacturing tools, program control manipulators, etc., can solve the problems of low repeat positioning accuracy, poor stiffness, cumbersome error analysis and control, etc., to reduce the difficulty of implementation, improve precision, and solve the problem of machining The effect of poor precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

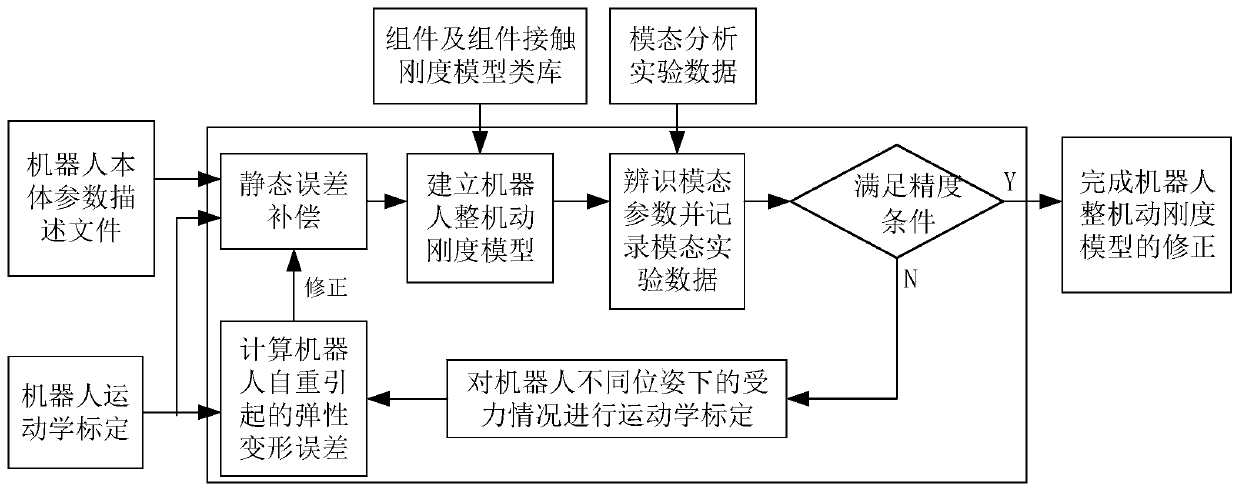

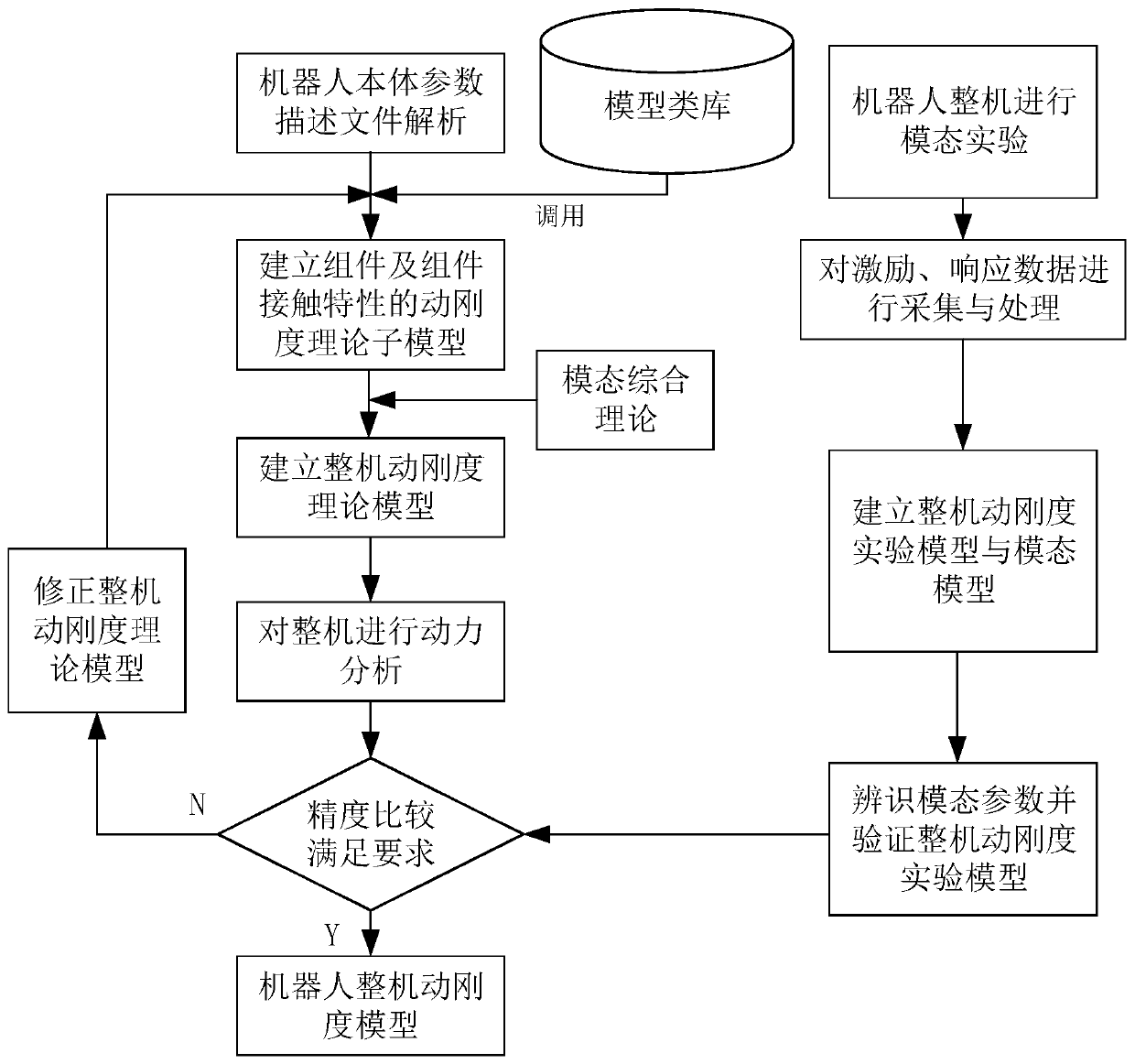

[0069] combined with figure 1 , this embodiment proposes a method for static error compensation and dynamic stiffness model correction of a cutting robot. The implementation process of this method includes:

[0070] Step S100 , perform kinematic calibration on the robot according to the description file of the robot body parameters, identify the structural parameters of the robot, perform static error compensation, and record measurement and calculation data during the calibration process.

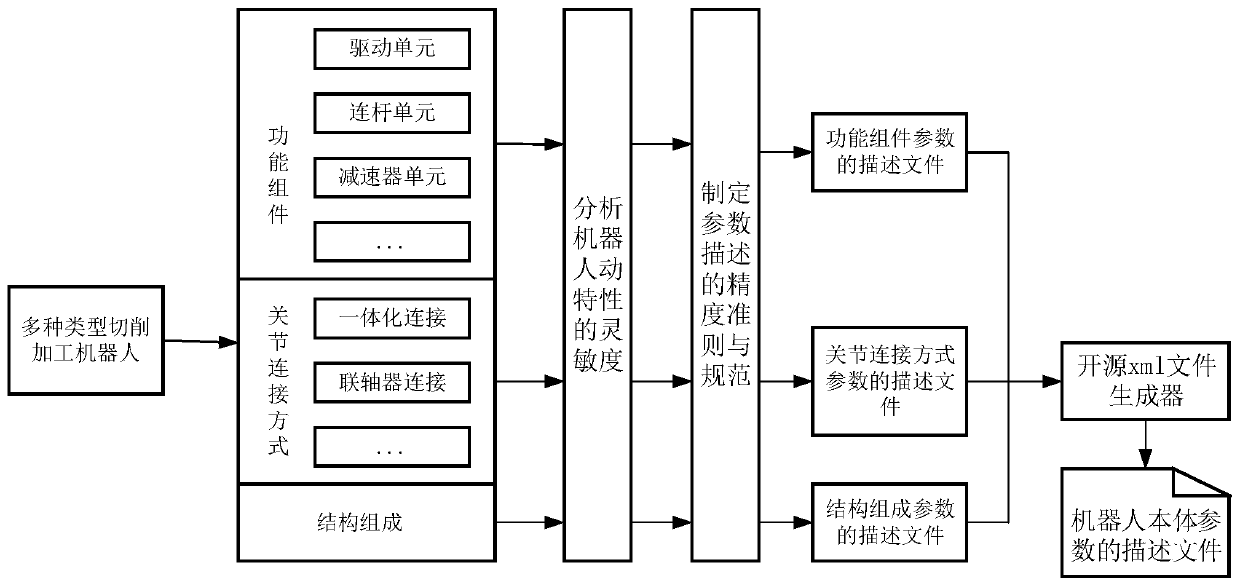

[0071] combined with figure 2 , in step S100, the description file of the robot body parameters involved is a normative file that can completely describe the robot body parameters, and the generation process of the description file includes:

[0072] S101. Analyze the sensitivity of the dynamic characteristics of the robot according to the structural parameters of the robot. The structural parameters include three types: functional components, joint connection methods, and structural com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com