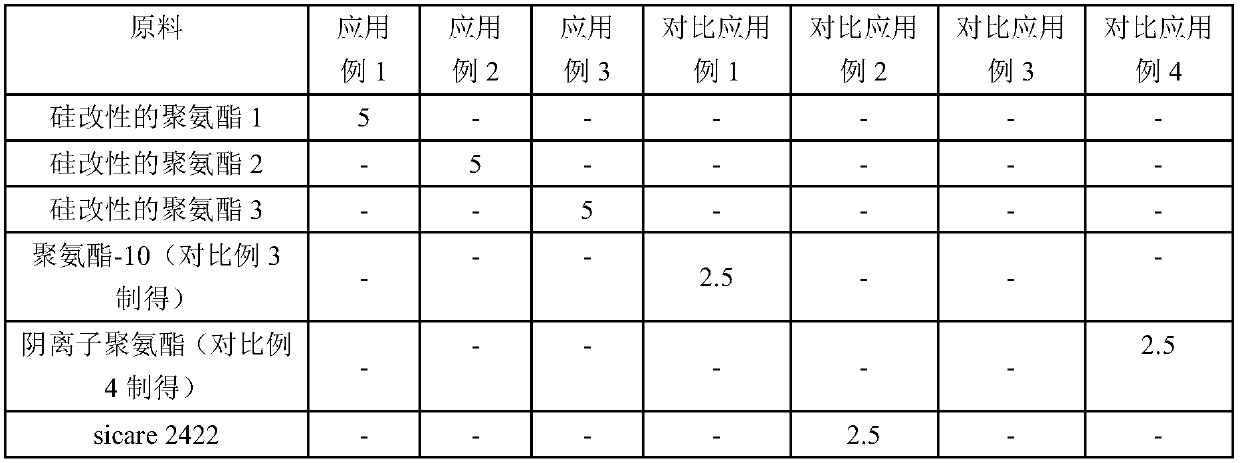

Non-ionic silicon-containing waterborne polyurethane dispersion and preparation thereof, and application of non-ionic silicon-containing waterborne polyurethane dispersion in hair cleaning

A water-based polyurethane, non-ionic technology, used in hair care, cosmetic preparations, cosmetic preparations, etc., can solve the problems of non-smoothness, excessive deposition of active ingredients in the hair, hair frizz, etc., and achieve the effect of increasing the spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

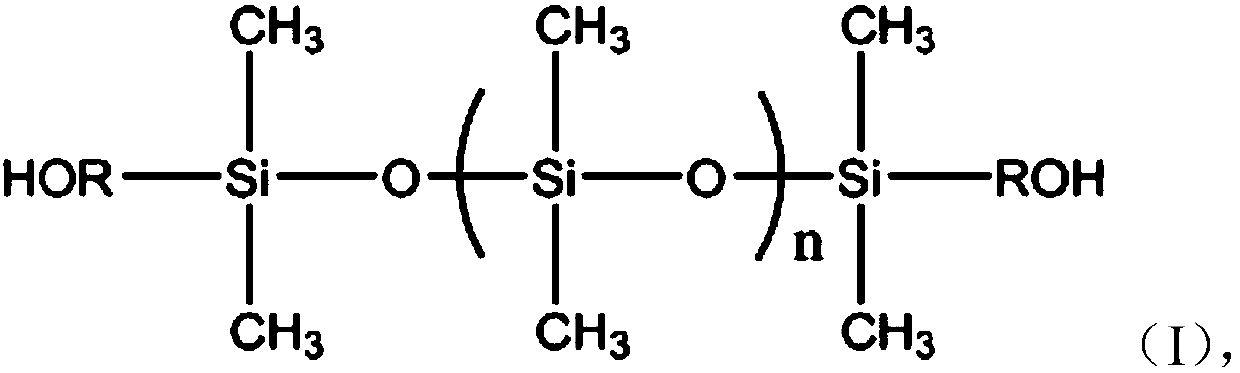

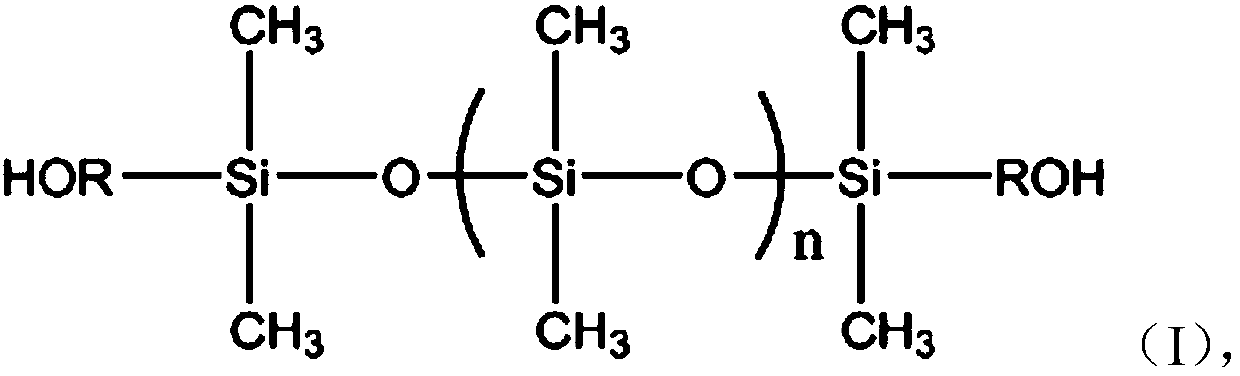

[0077] Example 1: Silicon-modified polyurethane 1

[0078] Add 48 grams of PPG1000, 9 grams of CHDM, 71 grams of N120, and 73 grams of KF6001 into a four-necked flask with a condenser and a stirrer, then add 65 grams of IPDI, 0.05 grams of organic bismuth 8108, and 26.6 grams of acetone at 75 ℃ for 1.5 hours, the NCO value is 1.97% (theoretical value is 2.07%);

[0079] After cooling down to 20°C, add 266 grams of acetone and 100 grams of sicare 2422;

[0080] Add 726 grams of water under high-speed (1400 rpm) shear dispersion, and stir for 5 minutes to obtain a coarse emulsion; then add a mixed solution of 3.2 grams of EDA and 13 grams of deionized water, stir and react for 10 minutes, and the reaction temperature is 35 ° C;

[0081] Afterwards, the solvent acetone was removed from the crude emulsion at 45° C. and 0.01 MPa vacuum condition to obtain a water-based polyurethane emulsion with a particle size (average particle size) d=40 nm and a solid content of 30 wt%.

Embodiment 2

[0082] Example 2: Silicon-modified polyurethane 2

[0083] Add 2 grams of PPG2000, 45 grams of CHDM, 109 grams of N120, and 154 grams of KF6002 into a four-necked flask with a condenser and a stirrer, then add 167 grams of HMDI, 0.07 grams of organic bismuth 8108, and 38.6 grams of acetone at 75 ℃ for 1.5 hours, the NCO value is 2.60% (theoretical value is 2.67%);

[0084] After cooling down to 20°C, add 243 grams of acetone and 140 grams of sicare 2422;

[0085] Add 1036 grams of water under high-speed (1500 rpm) shear dispersion, stir for 5 minutes to obtain a coarse emulsion, then add a mixed solution of 8 grams of EDA and 40 grams of deionized water, continue stirring for 10 minutes, and the reaction temperature is 40 ° C;

[0086] The coarse emulsion was desolventized with acetone at 45° C. and 0.01 MPa vacuum conditions to obtain a water-based polyurethane emulsion with a particle size (average particle size) d=60 nm and a solid content of 30 wt%.

Embodiment 3

[0087] Example 3: Silicon-modified polyurethane 3

[0088] Add 1 gram of PPG1000, 39.1 grams of CHDM, 5 grams of 1,4-butanedithiol, 109 grams of N120, and 90 grams of KF6001 into a four-necked flask with a condenser and a stirrer, and then add 141 grams of IPDI, 0.07 Gram organic bismuth 8108, 38.6 grams of acetone, reacted at 75°C for 1.5 hours, the NCO value was 3.15% (theoretical value was 3.26%);

[0089] After cooling down to 20°C, add 386 grams of acetone and 140 grams of sicare 2422;

[0090] Add 1036 grams of water under shear dispersion at 1500 rpm, stir for 5 minutes to obtain a coarse emulsion, then add a mixed solution of 8 grams of EDA and 40 grams of deionized water, continue stirring for 10 minutes, and the reaction temperature is 40 ° C;

[0091] The coarse emulsion was desolventized with acetone at 45° C. and 0.01 MPa vacuum conditions to obtain an aqueous polyurethane emulsion with an average particle diameter of d=60 nm and a solid content of 30 wt %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com