Glass-like polyurethane elastomer based on tertiary carbamate exchange, preparation method and application thereof

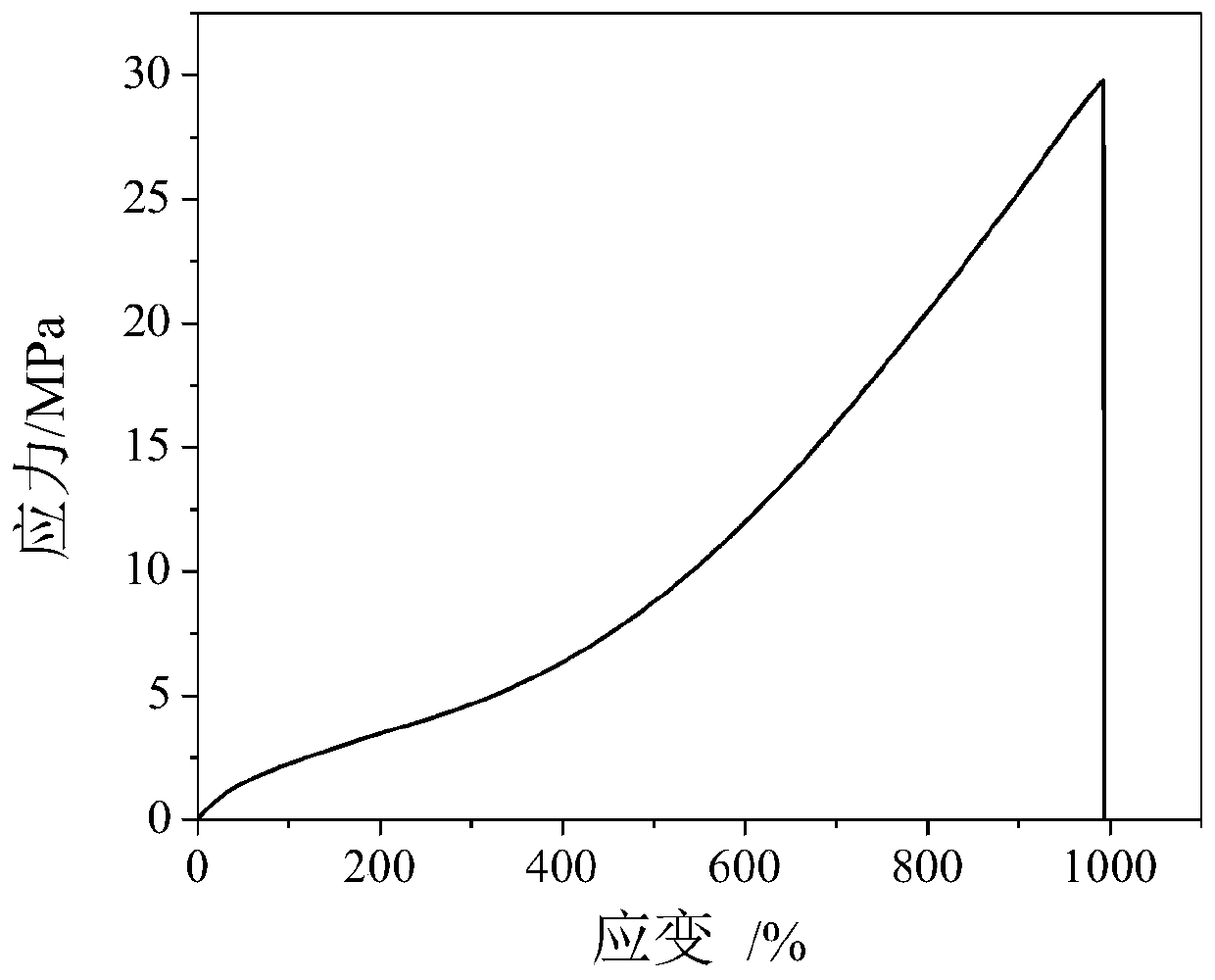

A polyurethane elastomer and carbamic acid technology, applied in the field of elastomers, can solve the problems of glass-like polyurethane elastomers that have not been seen, and achieve the effect of less reaction steps and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

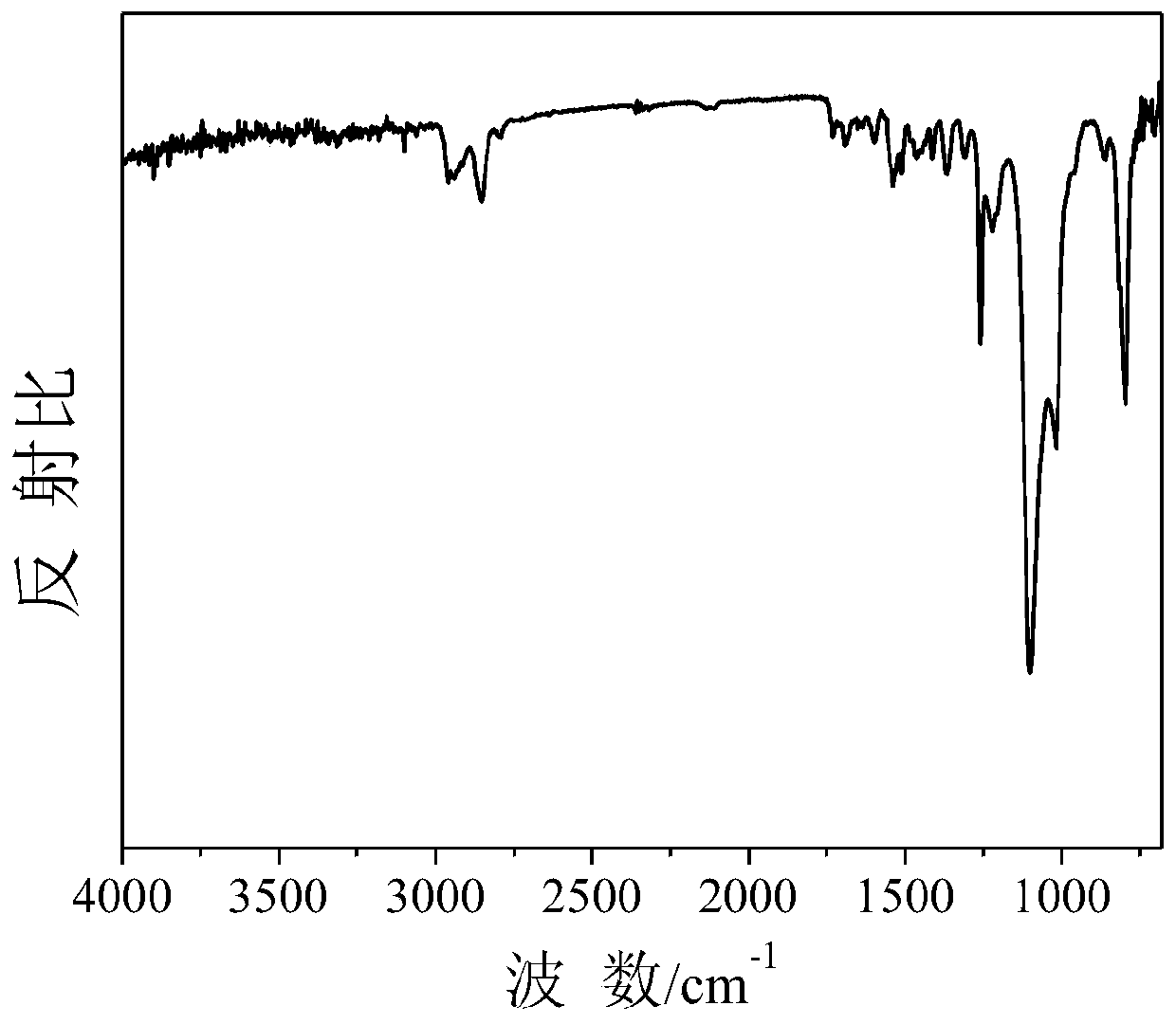

[0035] A glass-like polyurethane elastomer based on carbamic acid tertiary alcohol transesterification and a preparation method thereof. The preparation method described in this embodiment is:

[0036] Dehydrating 54-60 parts by mass of polymer diol at 100°C, and then reacting with 15-20 parts by mass of diisocyanate at 50°C to obtain an isocyanate-terminated prepolymer;

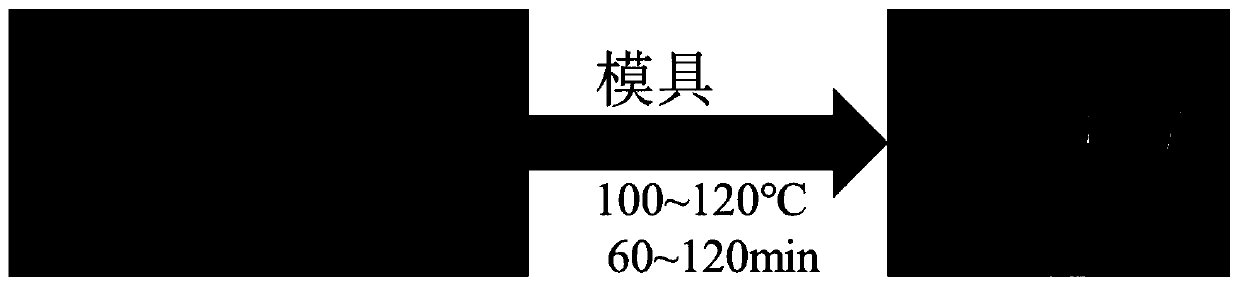

[0037] The prepolymer obtained in the steps is defoamed at 50°C, then mixed with 6-12 parts by mass of polyisocyanate and 8-16 parts by mass of dibasic tertiary alcohol chain extender in a solvent, and then defoamed at 20°C. foaming, pouring, and vulcanization at a certain temperature for a certain period of time to obtain the glass-like polyurethane elastomer based on tertiary alcohol carbamate.

[0038] The polymer diol is polytetrahydrofuran ether diol, and the number average molecular weight of the polymer diol is 1000.

[0039] The diisocyanate is diphenylmethane diisocyanate.

[0040] The polyisocya...

Embodiment 2

[0049] A glass-like polyurethane elastomer based on carbamic acid tertiary alcohol transesterification and a preparation method thereof. The preparation method described in this embodiment is:

[0050] Dehydrating 49-55 parts by mass of polymer diol at 110°C, and then reacting with 20-25 parts by mass of diisocyanate at 60°C to obtain an isocyanate-terminated prepolymer;

[0051] The prepolymer obtained in the steps is defoamed at 60°C, then mixed evenly with 4 to 8 parts by mass of polyisocyanate and 12 to 18 parts by mass of dihydric tertiary alcohol chain extender in a solvent, and defoamed at 30°C. foaming, pouring, and vulcanization at a certain temperature for a certain period of time to obtain the glass-like polyurethane elastomer based on tertiary alcohol carbamate.

[0052] The polymer diol is polytetrahydrofuran ether diol, and the number average molecular weight of the polymer diol is 3000.

[0053] The diisocyanate is diphenylmethane diisocyanate.

[0054] The p...

Embodiment 3

[0063] A glass-like polyurethane elastomer based on carbamic acid tertiary alcohol transesterification and a preparation method thereof. The preparation method described in this embodiment is:

[0064] Dehydrating 45-51 parts by mass of polymer diol at 120°C, and then reacting with 20-25 parts by mass of diisocyanate at 75°C to obtain an isocyanate-terminated prepolymer;

[0065] The prepolymer obtained in the steps is defoamed at 75°C, then mixed with 6-12 mass parts of polyisocyanate and 14-20 mass parts of dibasic tertiary alcohol chain extender in a solvent, and degassed at 40°C. foaming, pouring, and vulcanization at a certain temperature for a certain period of time to obtain the glass-like polyurethane elastomer based on tertiary alcohol carbamate.

[0066] The polymer diol is polyethylene glycol, and the number average molecular weight of the polymer diol is 2000.

[0067] The diisocyanate is hexamethylene diisocyanate.

[0068] The polyisocyanate crosslinking agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com