Stepwise yarn sizing pulp and sizing method

A step-by-step, sizing technology, which is applied in the field of textile sizing, can solve the problems of expensive sizing, failure to achieve both warp strength and wear resistance, and increased sizing costs, so as to facilitate industrial production and increase the rate of wear resistance. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

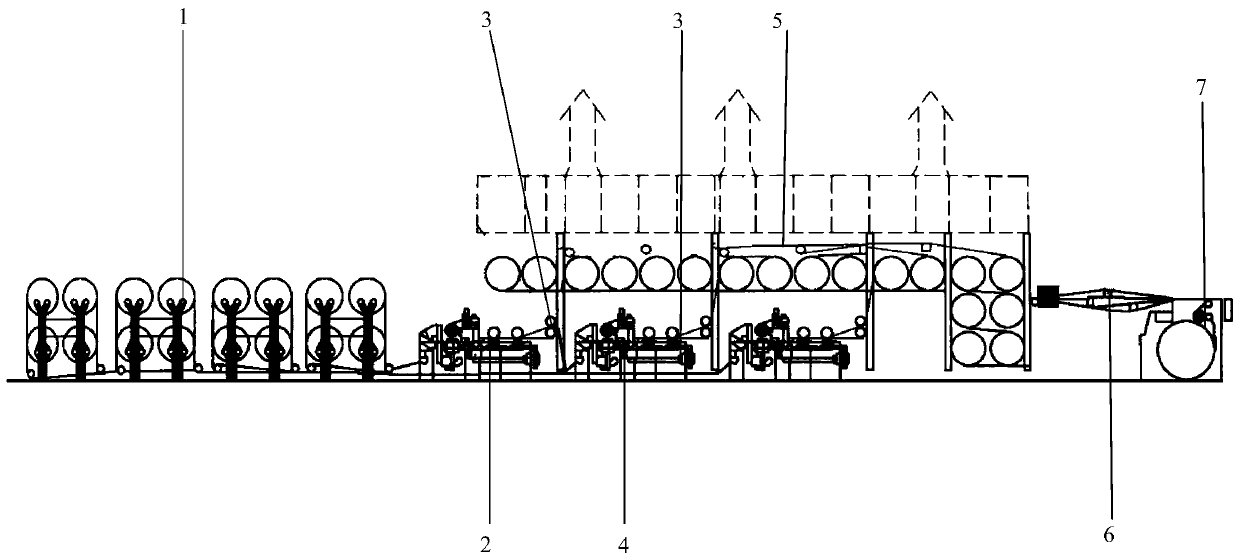

Method used

Image

Examples

Embodiment 1

[0050] The step-by-step sizing size of the yarn in the present invention is composed of an inner soaking size and an outer coating size, the inner soaking size is a mixture of starch, propylene and water, and the outer coating size is a polyester A mixture of vinyl alcohol and water.

[0051] The compound mass ratio of starch and acrylic acid is 3.2:1.

[0052] Starch is a mixture of high-performance modified starch, phosphate starch and corn starch.

[0053] Acrylics are a mixture of propylene and acrylates.

[0054] The mass concentration of the internal soaking slurry was 7%.

[0055] The mass concentration of the outer coating slurry is 3%.

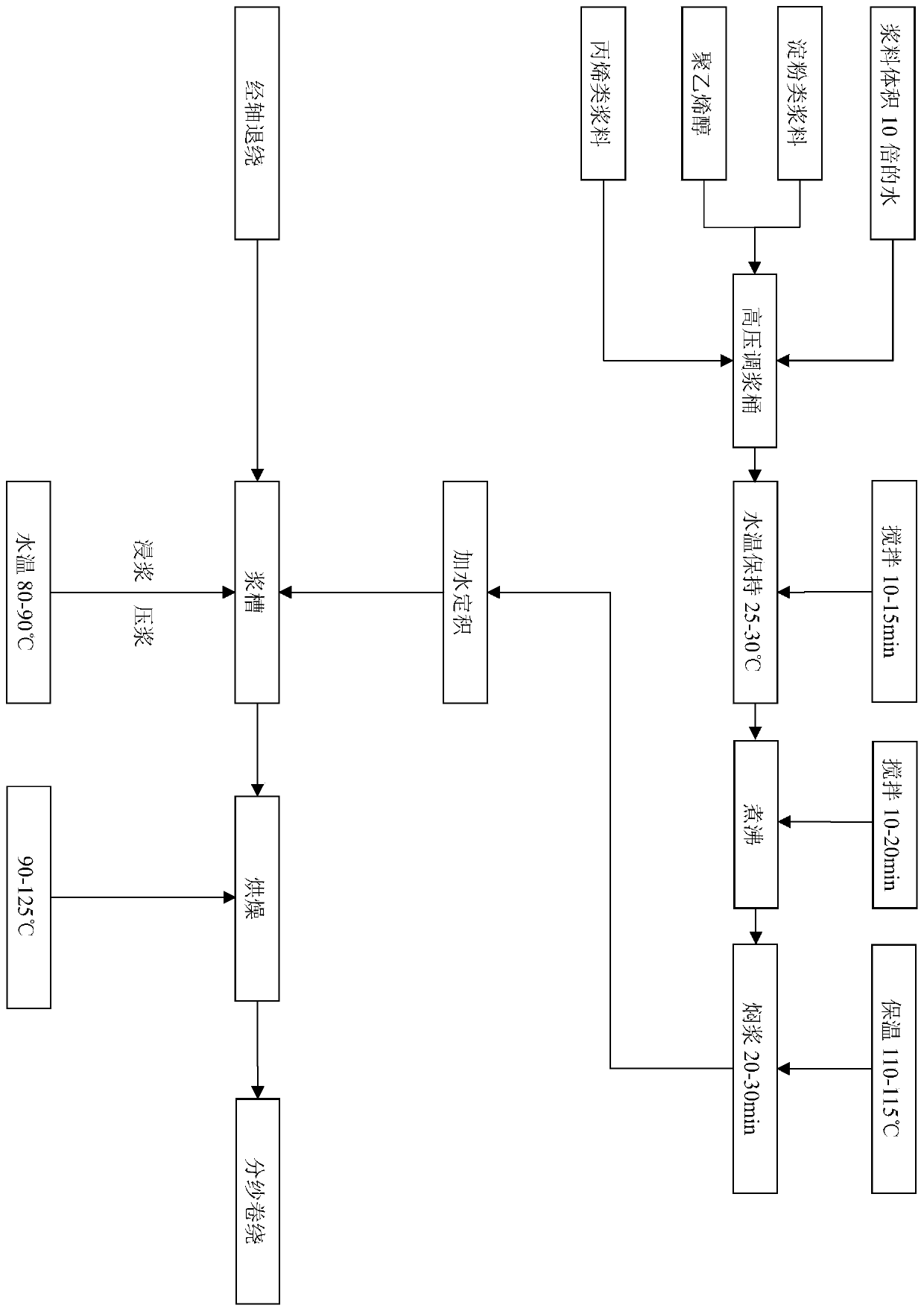

[0056] Implementation kind is worsted 14.57tex pure cotton yarn fabric, and the sizing method of step-by-step sizing size of yarn of the present invention comprises the following steps:

[0057] (1) Preparation of internal impregnation slurry

[0058] Put 25Kg of high-performance modified starch, 50Kg of phosphate starch, 25Kg of c...

Embodiment 2

[0075] The step-by-step sizing size of the yarn in the present invention is composed of an inner soaking size and an outer coating size, the inner soaking size is a mixture of starch, propylene and water, and the outer coating size is a polyester A mixture of vinyl alcohol and water.

[0076] The compound mass ratio of starch and acrylic acid is 3.5:1.

[0077] Starch is a mixture of high-performance modified starch, phosphate starch and corn starch.

[0078] Acrylics are a mixture of propylene and acrylates.

[0079] The mass concentration of the internal soaking slurry was 9%.

[0080] The mass concentration of the outer coating slurry is 4%.

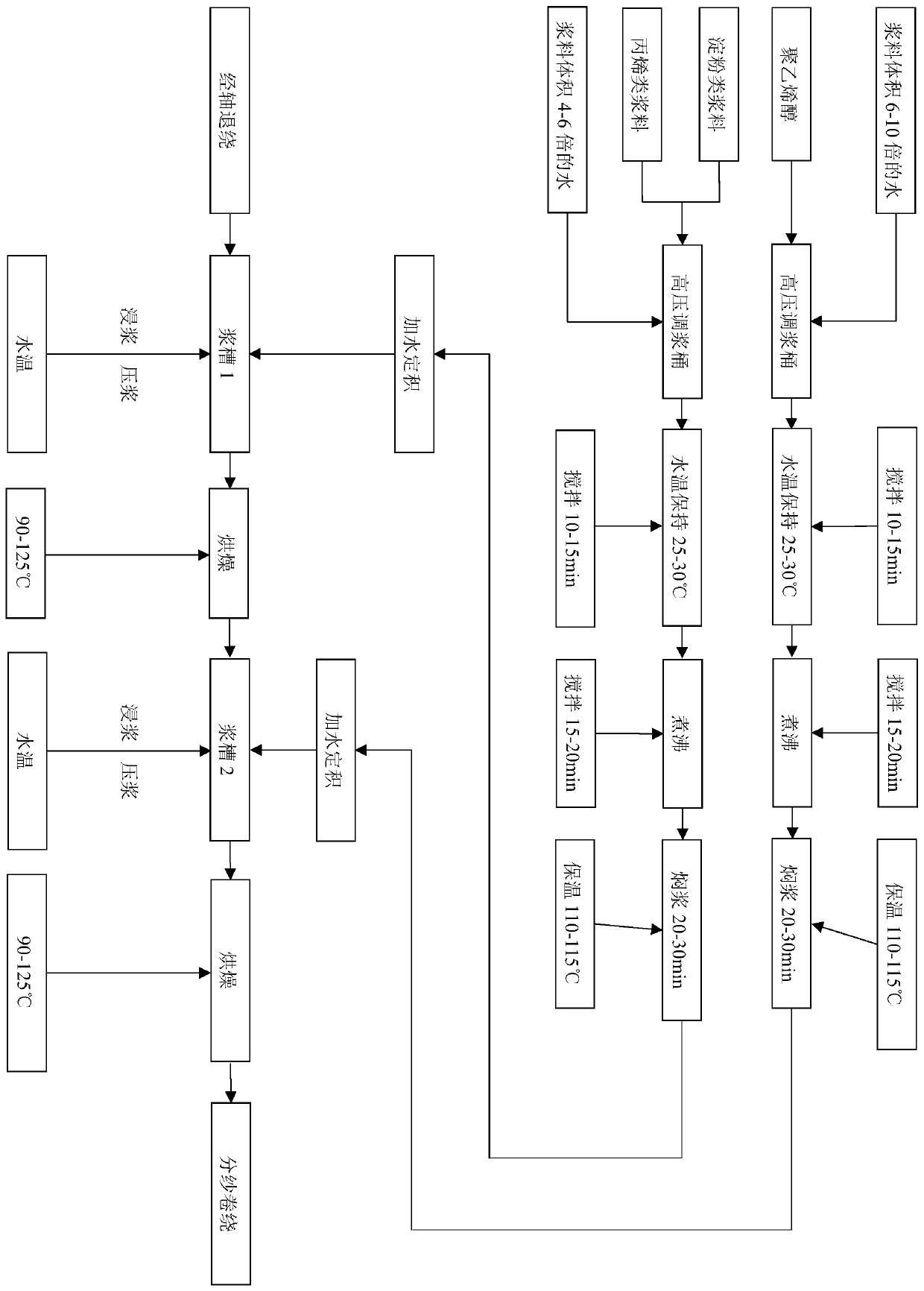

[0081] Implementation kind is worsted 11.67tex pure cotton yarn fabric, and the sizing method of step-by-step sizing size of yarn of the present invention comprises the following steps:

[0082] (1) Preparation of internal impregnation slurry

[0083] Put 60Kg of high-performance modified starch, 25Kg of phosphate starch, 25Kg of...

Embodiment 3

[0100] The step-by-step sizing size of the yarn in the present invention is composed of an inner soaking size and an outer coating size, the inner soaking size is a mixture of starch, propylene and water, and the outer coating size is a polyester A mixture of vinyl alcohol and water.

[0101] The compounding mass ratio of starch and acrylic acid is 4:1.

[0102] Starch is a mixture of high-performance modified starch and corn starch.

[0103] Acrylics are a mixture of propylene and acrylates.

[0104] The mass concentration of the internal soaking slurry was 11%.

[0105] The mass concentration of the outer coating slurry is 5%.

[0106] Implementation kind is worsted 8.33tex pure cotton yarn fabric, and the sizing method of step-by-step sizing of yarn of the present invention comprises the following steps:

[0107] (1) Preparation of internal impregnation slurry

[0108]Put 75Kg of high-performance modified starch, 25Kg of cornstarch, 25Kg of solid propylene, 30Kg of acr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com