Fungus grinding and uniform stirring equipment for fungus milk processing

A technology of grinding and fungus, applied in the direction of application, mixer with rotating stirring device, mixer, etc., can solve the problems of insufficient grinding, affecting quality, etc., and achieve the effect of improving the overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

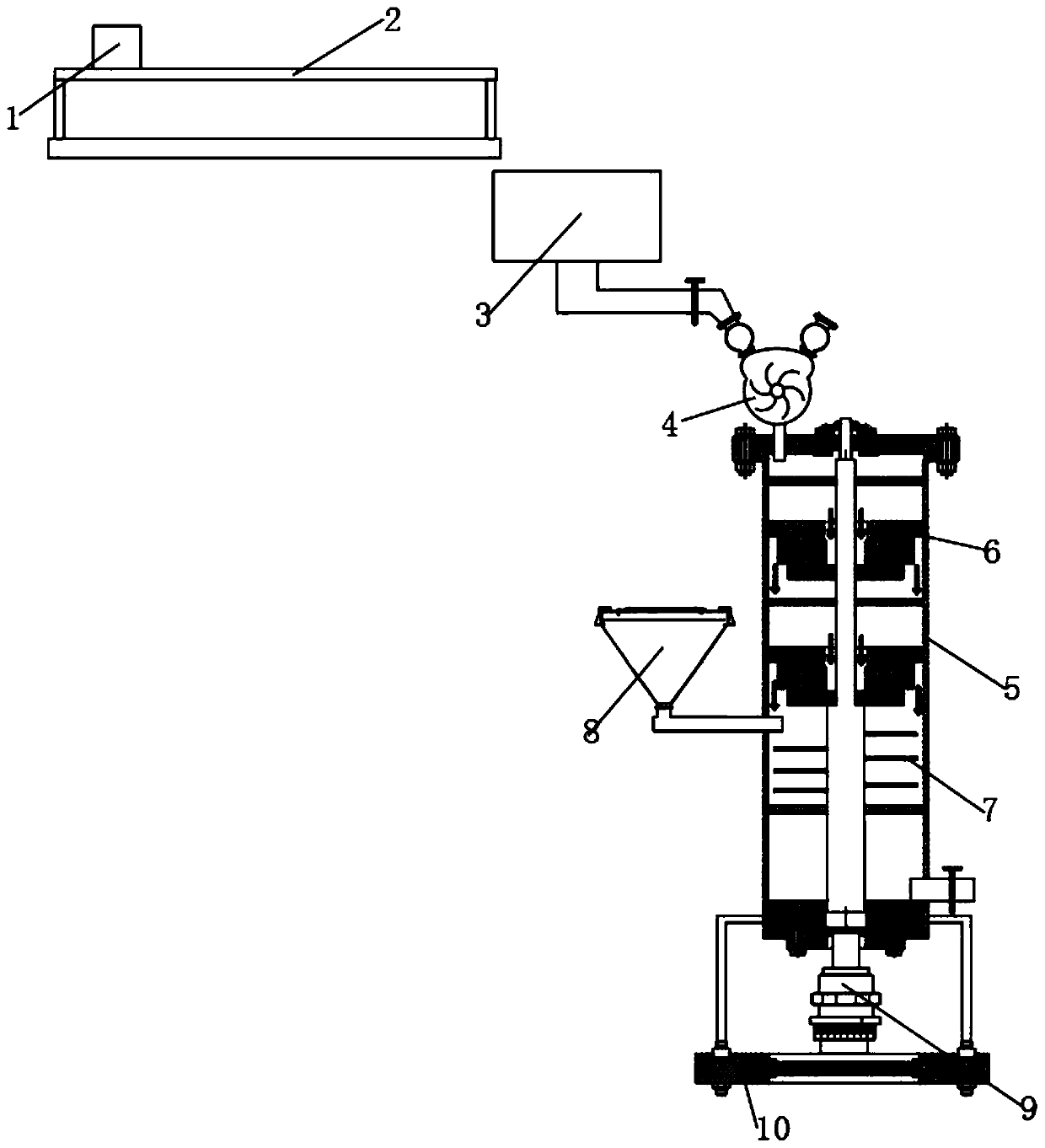

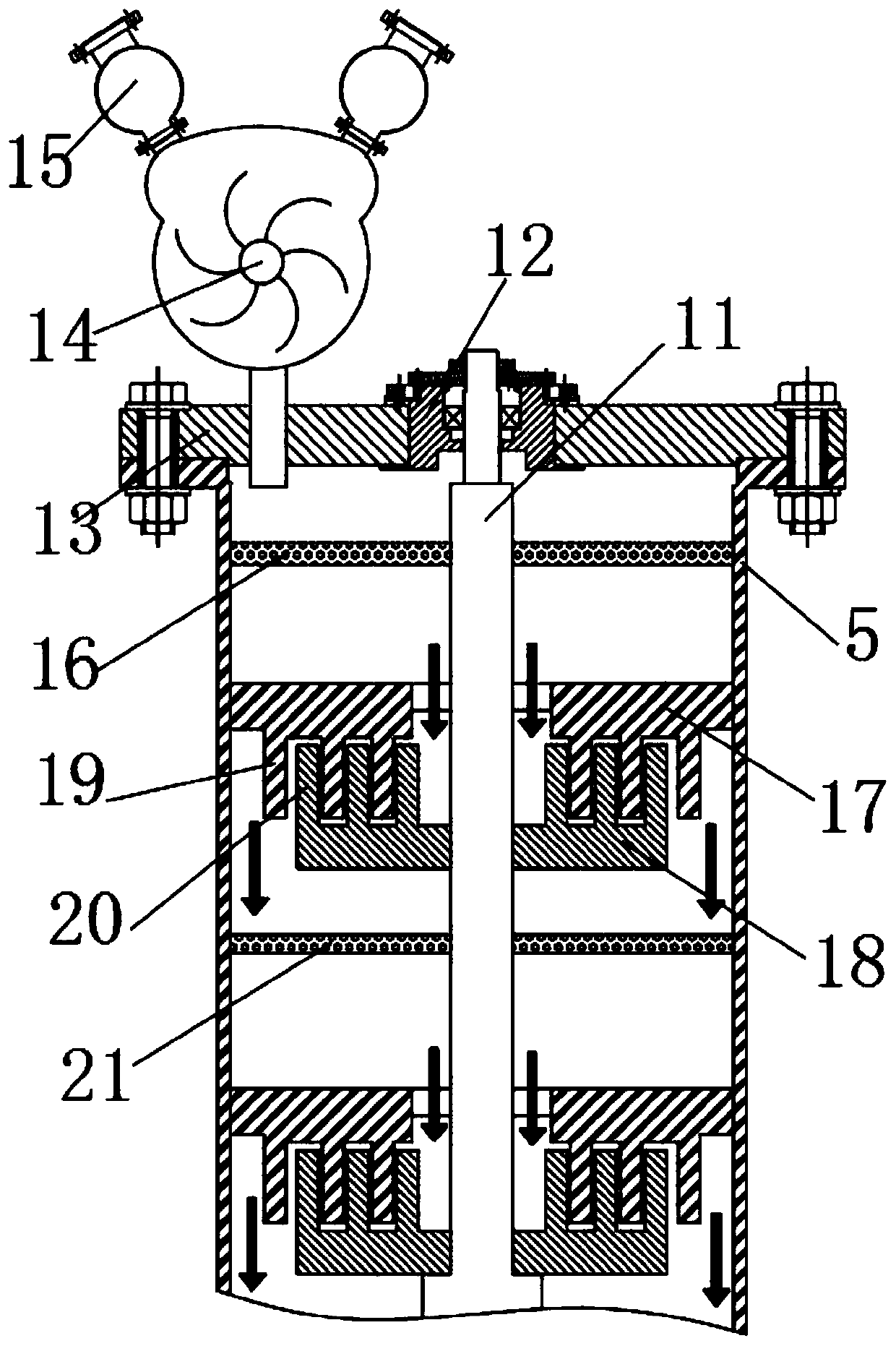

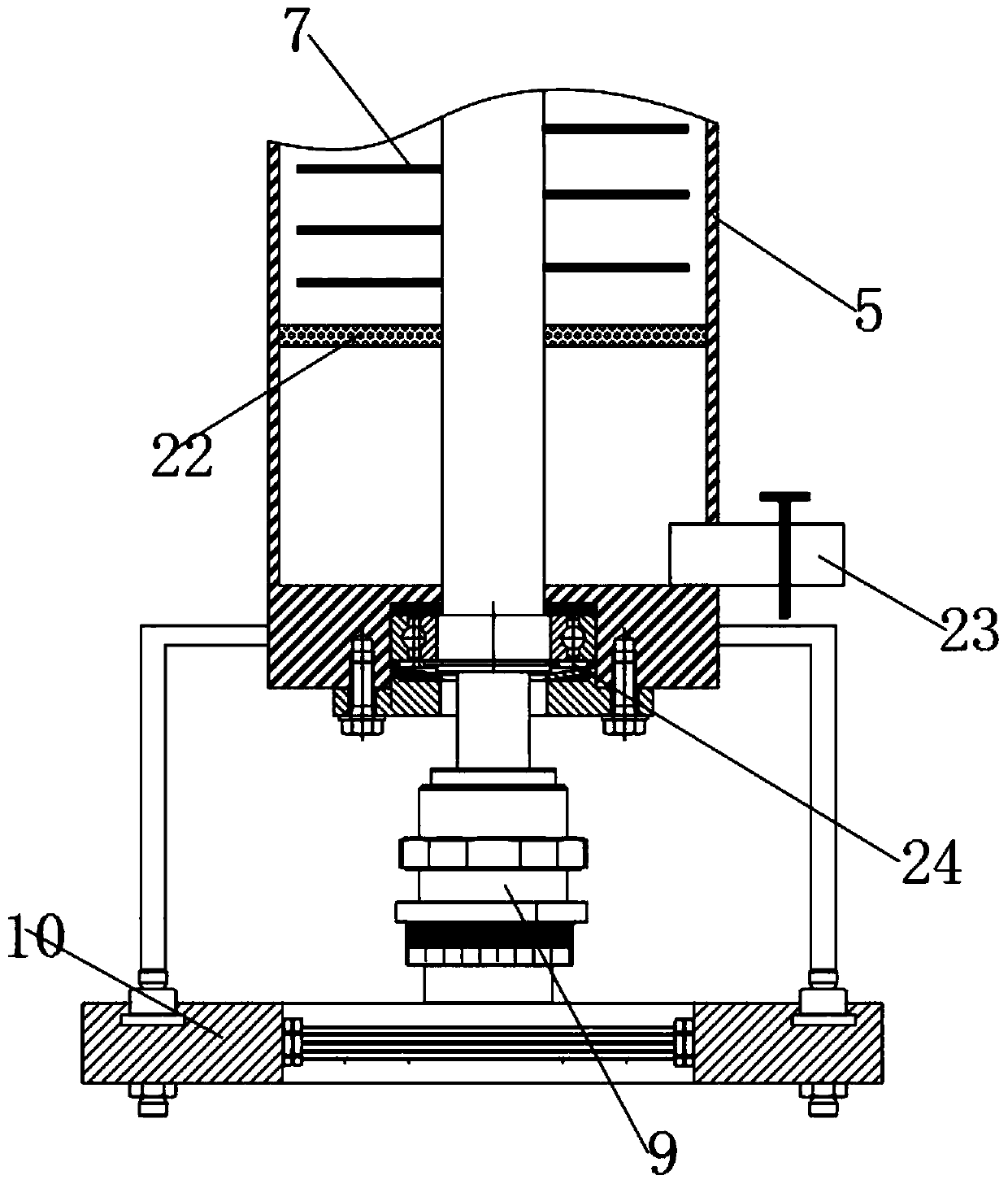

[0022] Example: see Figure 1-4 , the present invention provides a technical solution: a fungus grinding and mixing equipment for bacterial milk processing, which includes a drying component, a mixing component, a grinding component and a feeding and mixing component, and the drying component is sleeved on The outside of the slide plate 2 is used to dry the fungus in the collection bin 1, and the dried fungus enters the temporary storage tank 3 and is mixed with the added product by the mixing component to form a mixture. The homogenizing components are all arranged in the tank body 5, and the supplementary mixing component is arranged under the grinding component, and the mixed product is processed by the grinding component and the supplementary mixing component in turn to form a primary product.

[0023] Wherein, the collection bin 1 is slidably arranged on the slide plate 2 and moves from the left end of the slide plate 2 to the right end of the slide plate 2 through the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com