A kind of aluminum foil-based aluminum-fumaric acid mof adsorbent coating and its mixed solvent in-situ synthesis method and application

A technology of in-situ synthesis and mixed solvent, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve the problem of low water adsorption, achieve good mass transfer performance, not easy to drop powder and fall off, load high volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

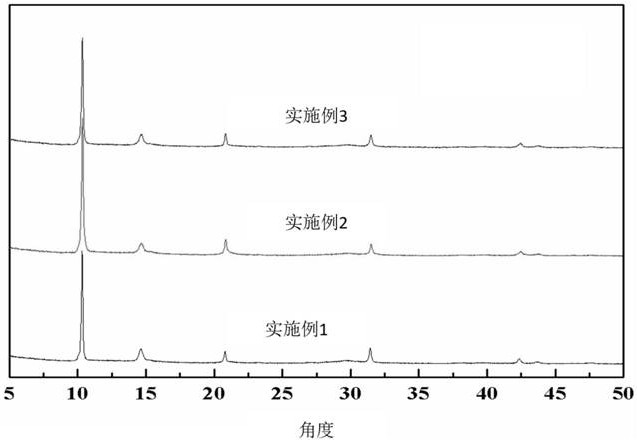

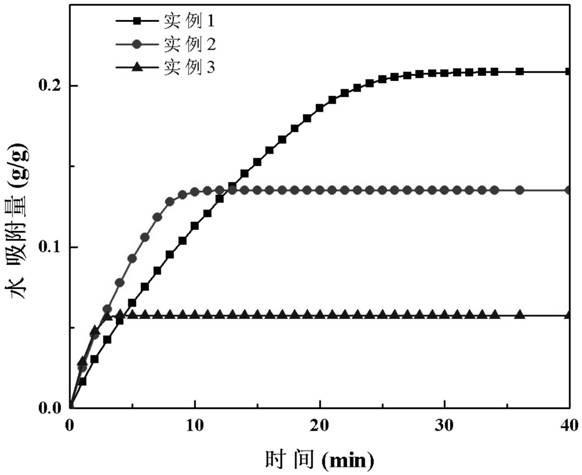

Embodiment 1

[0046] A mixed solvent in-situ synthesis method for an aluminum foil-based aluminum-fumaric acid MOF adsorbent coating, comprising the following steps:

[0047] (1) In a 100mL beaker, add 0.4872g (4.2mmol) of fumaric acid to 10ml of nitrogen, nitrogen-dimethylformamide (DMF), and mix well under magnetic stirring to obtain a fumaric acid solution; in another 100mL beaker 1.33g (2mmol) aluminum salt (select Al 2 (SO 4 ) 3 ·18H 2 0) add 20ml deionized water, mix homogeneously, obtain aluminum salt solution; Then mix described fumaric acid solution and aluminum salt solution homogeneously, obtain mixed solution, the volume of described nitrogen, nitrogen-dimethylformamide and water The ratio is 1:2; in the mixed solution, the fumaric acid and Al 3+ The molar ratio of acetic acid is 1.05:1, and the pH of the mixed solution is adjusted to be 1.0 by adding glacial acetic acid dropwise to obtain a uniform acidic reaction solution;

[0048] (2) Scrape off the oxide film on the sur...

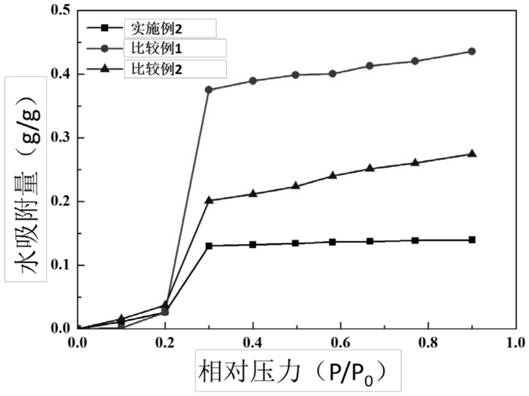

Embodiment 2

[0051] A mixed solvent in-situ synthesis method for an aluminum foil-based aluminum-fumaric acid MOF adsorbent coating, comprising the following steps:

[0052] (1) In a 100mL beaker, add 0.2552g (2.2mmol) fumaric acid to 15ml nitrogen, nitrogen-dimethylformamide (DMF), and mix well under magnetic stirring to obtain a fumaric acid solution; in another 100mL beaker 0.666g (1mmol) aluminum salt (select Al 2 (SO 4 ) 3 ·18H 2 O) add 15ml deionized water, mix homogeneously, obtain aluminum salt solution; Then mix described fumaric acid solution and aluminum salt solution homogeneously, obtain mixed solution, the volume of described nitrogen, nitrogen-dimethylformamide and water The ratio is 1:1; in the mixed solution, the fumaric acid and Al 3+ The molar ratio of acetic acid is 1.1:1, and the pH of the mixed solution is adjusted to 1.5 by adding glacial acetic acid dropwise to obtain a uniform acidic reaction solution;

[0053] (2) Scrape off the oxide film on the surface of t...

Embodiment 3

[0056] A mixed solvent in-situ synthesis method for an aluminum foil-based aluminum-fumaric acid MOF adsorbent coating, comprising the following steps:

[0057] (1) In a 100mL beaker, add 0.1392g (1.2mmol) fumaric acid to 12.5ml nitrogen, nitrogen-dimethylformamide (DMF), and mix well under magnetic stirring to obtain a fumaric acid solution; in another 100mL 0.333g (0.5mmol) aluminum salt (select Al 2 (SO 4 ) 3 ·18H 2 O) add 17.5ml deionized water, mix homogeneously, obtain aluminum salt solution; Then mix described fumaric acid solution and aluminum salt solution homogeneously, obtain mixed solution, described nitrogen, nitrogen-dimethylformamide and water The volume ratio is 0.714:1; in the mixed solution, the fumaric acid and Al3+ The molar ratio of the mixture is 1.2:1, and glacial acetic acid is added dropwise to adjust the pH of the mixed solution to be 2.0 to obtain a uniform acidic reaction solution;

[0058] (2) Scrape off the oxide film on the surface of the alu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com