Processing method of silicon base substrate

A processing method and substrate technology, which are applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of device process difficulty and large flatness of epitaxial materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

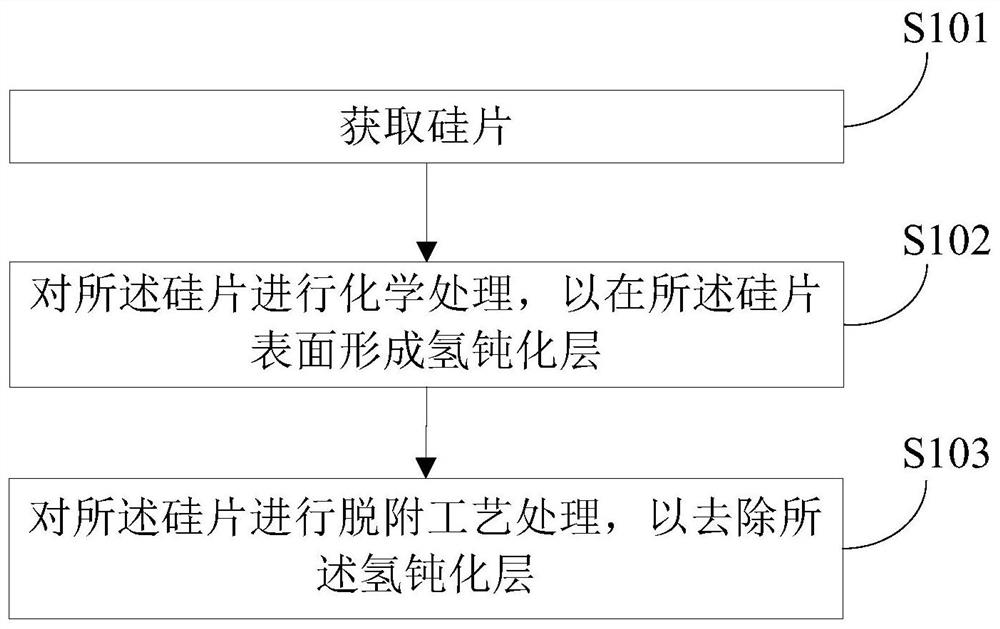

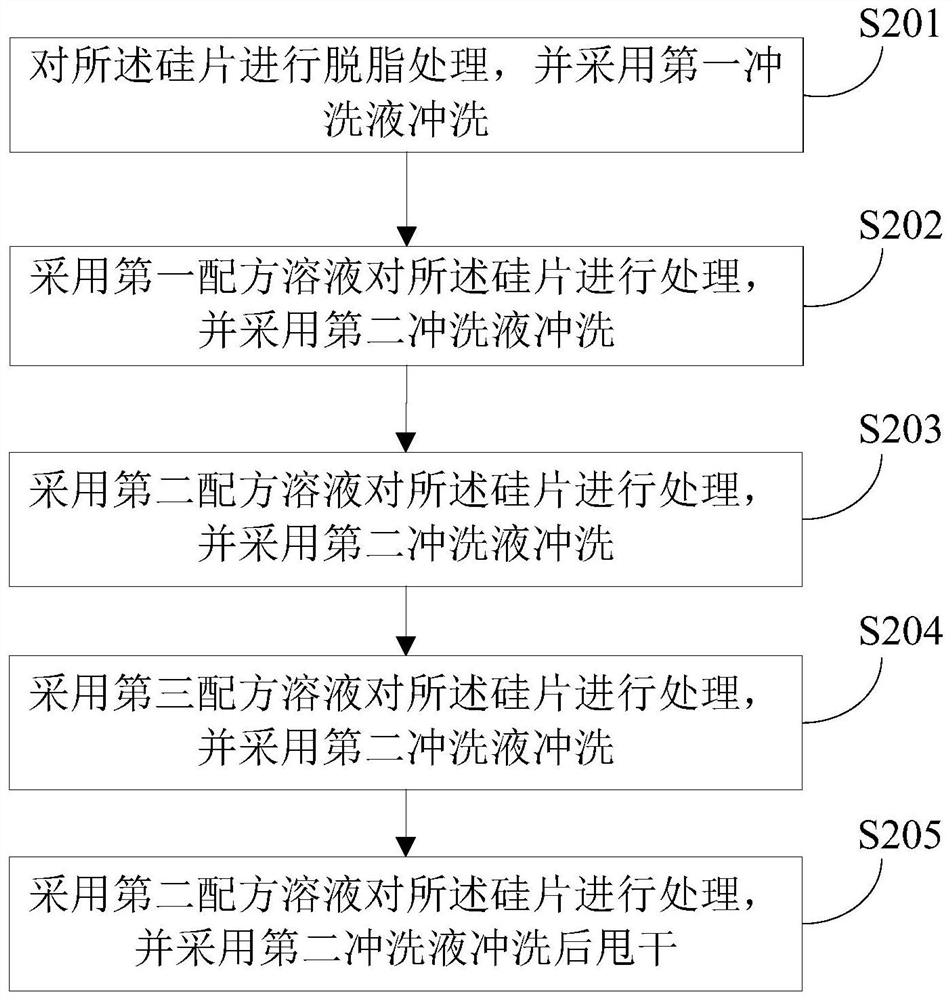

[0034] In order to further explain the technical means and functions adopted by the present invention to achieve the intended purpose, the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0035] A high-quality Si-based CdTe composite substrate is an important prerequisite for the preparation of Si-based HgCdTe materials. In related technologies, the Si wafer epitaxial material needs to be wet chemically cleaned to remove the dense oxide layer on the surface, and then form a new oxide layer. The natural oxide layer on the surface of the Si sheet is relatively dense, and it needs to be heated above 1000°C in the MBE system to desorb. However, under such high temperature conditions, the Si sheet is easily damaged and new impurities will be introduced.

[0036] The new oxide layer after wet chemical treatment has only 1-2 atomic layers, which is relatively easy to remove while protecting the surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| warpage | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com