Treatment method for improving safety of liquid light hydrocarbon storing tank

A treatment method and safe technology, applied in the direction of pretreatment surface, cleaning method and utensils, chemical instruments and methods, etc., can solve the problems of complex structure, unsuitable for the promotion and use of collection tanks, etc. Performance and anti-corrosion ability, enhance the effect of conductivity and antistatic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

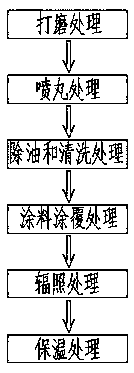

Image

Examples

Embodiment 1

[0034] A treatment method for improving the safety of a tank containing liquid light hydrocarbons, which involves performing special surface treatment on the inner surface of the tank, and the surface treatment method specifically includes the following steps:

[0035] (1) Grinding the inner surface of the tank, the number of sandpaper used for grinding is 300~800 mesh; the purpose of this grinding is mainly to repair the inner surface of the tank, and select the corresponding grinding sandpaper according to the different tank body;

[0036] (2) Shot peening is carried out on the inner surface of the tank, and the medium used to control shot peening during shot peening is corundum sand;

[0037] (3) Degreasing and cleaning the inner surface of the tank. The degreasing liquid used for degreasing is acetone solution, and the solution used for cleaning is deionized water;

[0038] (4) Coating the inner surface of the tank with paint. The ingredients and corresponding weight parts...

Embodiment 2

[0047] A treatment method for improving the safety of a tank containing liquid light hydrocarbons, which involves performing special surface treatment on the inner surface of the tank, and the surface treatment method specifically includes the following steps:

[0048] (1) Grinding the inner surface of the tank, the number of sandpaper used for grinding is 300~800 mesh; the purpose of this grinding is mainly to repair the inner surface of the tank, and select the corresponding grinding sandpaper according to the different tank body;

[0049] (2) Shot peening is carried out on the inner surface of the tank, and the medium used to control shot peening during shot peening is corundum sand;

[0050] (3) Degreasing and cleaning the inner surface of the tank. The degreasing liquid used for degreasing is acetone solution, and the solution used for cleaning is deionized water;

[0051] (4) Paint coating treatment on the inner surface of the tank. The components and corresponding weigh...

Embodiment 3

[0060] A treatment method for improving the safety of a tank containing liquid light hydrocarbons, which involves performing special surface treatment on the inner surface of the tank, and the surface treatment method specifically includes the following steps:

[0061] (1) Grinding the inner surface of the tank, the number of sandpaper used for grinding is 300~800 mesh; the purpose of this grinding is mainly to repair the inner surface of the tank, and select the corresponding grinding sandpaper according to the different tank body;

[0062] (2) Shot peening is carried out on the inner surface of the tank, and the medium used to control shot peening during shot peening is corundum sand;

[0063] (3) Degreasing and cleaning the inner surface of the tank. The degreasing liquid used for degreasing is acetone solution, and the solution used for cleaning is deionized water;

[0064] (4) Coating the inner surface of the tank with paint. The ingredients and corresponding weight parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com