Hybrid commercial vehicle electrical system using solar energy and waste gas waste heat power generation

A technology of waste heat power generation and hybrid power, applied in hybrid vehicles, electric braking systems, electric vehicles, etc., can solve the problems of engine fuel economy and power performance optimization, recovery, engine power assistance and braking energy, etc. To achieve the effect of improving fuel economy and power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

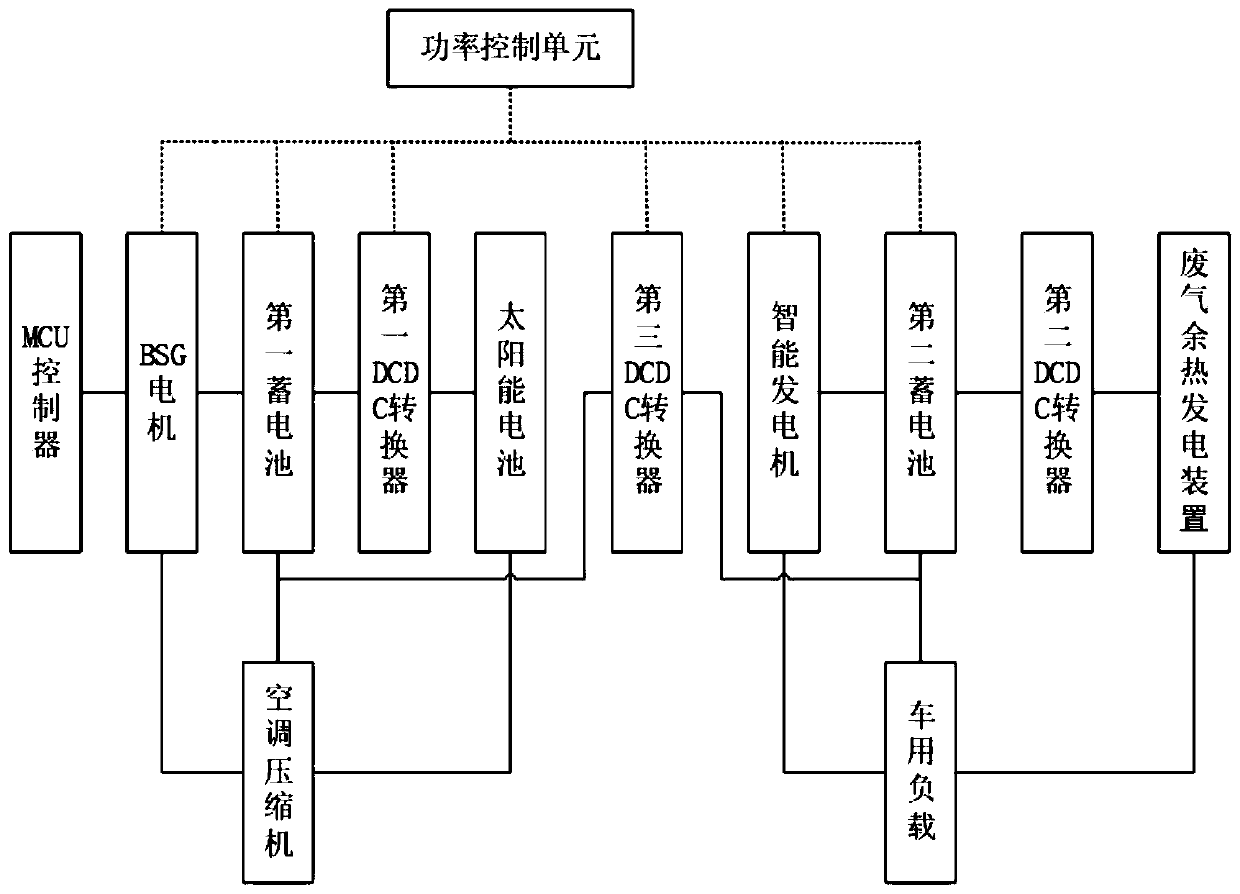

[0032] See figure 1 As shown, an embodiment of the present invention provides an electrical system for a hybrid commercial vehicle that generates power from solar energy and waste heat from exhaust gas, including:

[0033] The first power generation unit. The circuit system of the first power generation unit is 48 volts. The first power generation unit includes a BSG motor and a solar battery. The BSG motor is connected to the crankshaft pulley of the engine through a belt, and the BSG motor is electrically connected to the first battery. The solar cell is provided with a first DCDC converter, and the solar cell is electrically connected to the first storage battery through the first DCDC converter.

[0034] During driving, the BSG motor can provide power assistance for the engine. When the vehicle receives a starting command, the first battery outputs electric energy to drive the BSG motor to run. The BSG motor transmits the starting torque to the crankshaft pulley through the be...

Embodiment 2

[0047] See figure 1 As shown, the embodiment of the present invention provides a hybrid commercial vehicle electrical system for generating electricity from solar energy and waste heat from exhaust gas. The difference between this embodiment and Embodiment 1 is that the first power generation unit also includes an air conditioning compressor and a power control unit. The machine is electrically connected in parallel with the BSG motor, the solar cell, and the first battery. The power control unit is electrically connected to the BSG motor and the first battery, and the power control unit is used to detect the remaining power of the first battery and control the BSG motor to charge the first battery.

[0048] The voltage of the air conditioner compressor is 48 volts, the voltage of the BSG motor is 48 volts, the direct current from the solar cell is converted into 48 volts direct current through the first DCDC converter, and the voltage of the first battery is 48 volts. The BSG ...

Embodiment 3

[0050] See figure 1 As shown, the embodiment of the present invention provides a hybrid commercial vehicle electrical system for generating electricity from solar energy and waste heat from exhaust gas. The difference between this embodiment and Embodiment 1 is that the second power generation unit also includes a vehicle load and a power control unit. The load is electrically connected in parallel with the smart generator, the waste heat power generation device, and the second battery. The power control unit is electrically connected to the second battery and the smart generator, and the power control unit is used to detect the remaining power of the second battery and control the smart generator to charge the second battery.

[0051] The voltage of the vehicle load is 24 volts, the voltage of the smart generator is 24 volts, the direct current generated by the waste heat power generation device is converted into 24 volts direct current through the second DCDC converter, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com