A kind of polycarbonate/abs composition, preparation method and automobile pillar guard plate

A technology of polycarbonate and composition, which is applied in the field of polymer materials, can solve problems such as poor low-temperature toughness, and achieve high application value and good application prospects

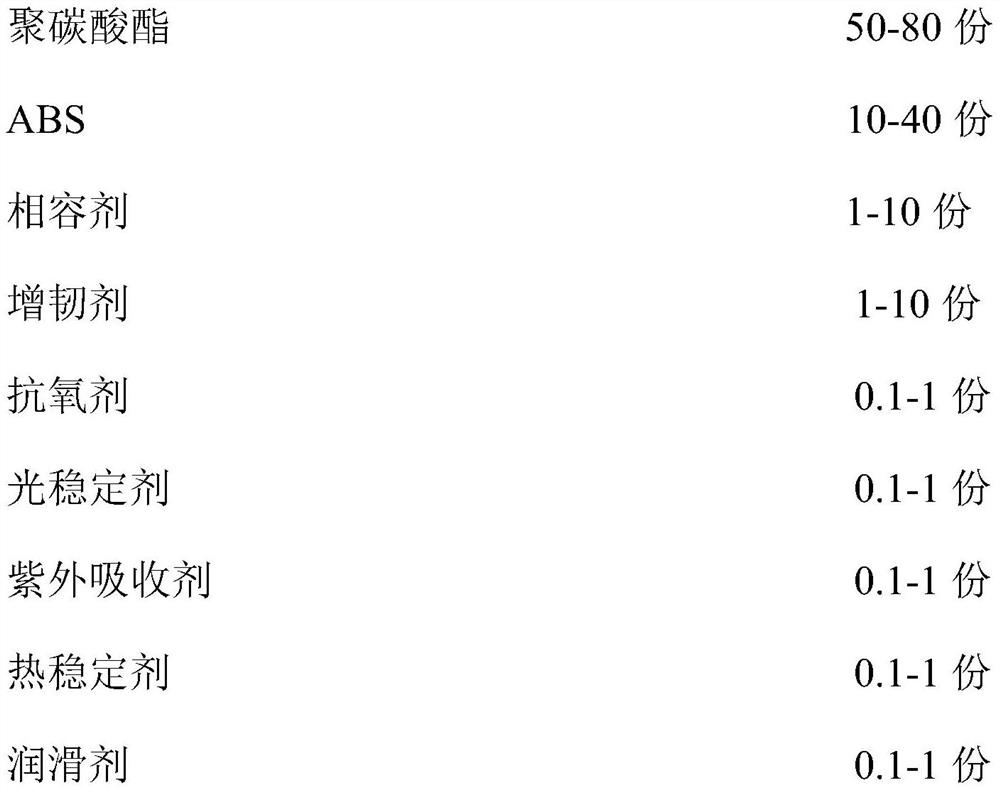

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

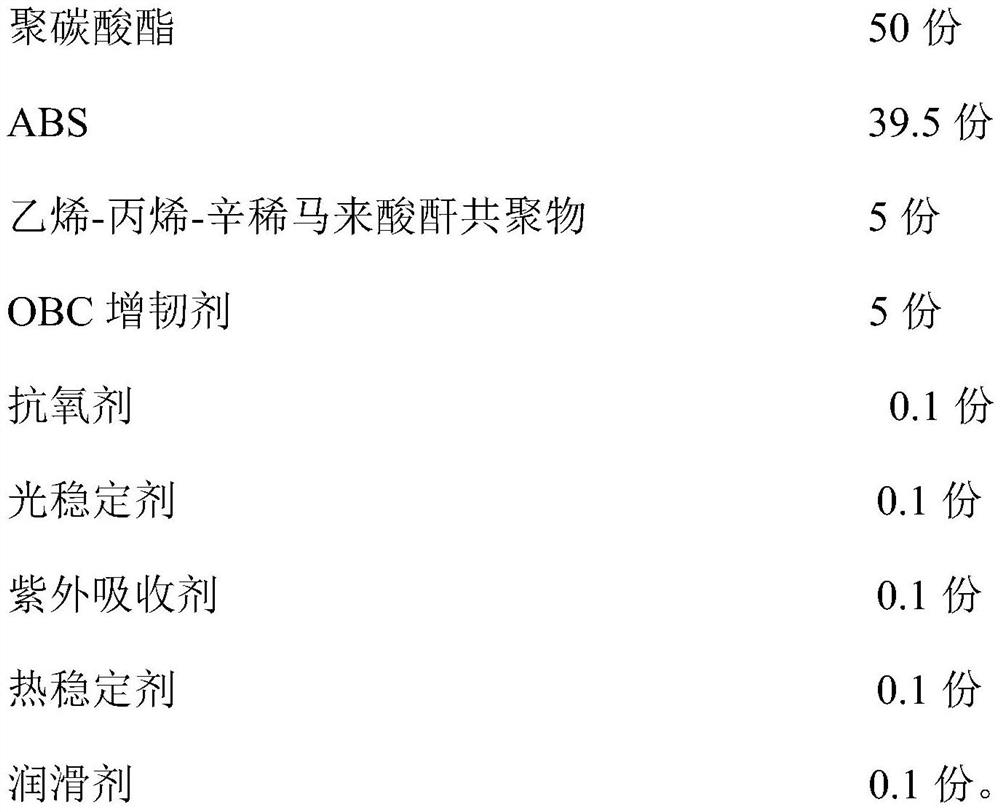

Embodiment 1

[0064] The polycarbonate / ABS composition provided by the present embodiment comprises the following components in parts by weight:

[0065]

[0066] Preparation:

[0067] (1) Polycarbonate, ABS resin and ethylene-propylene-octene maleic anhydride copolymer, OBC toughening agent, antioxidant, light stabilizer, ultraviolet absorber, heat stabilizer, and lubricant are mixed Blending in the machine until uniform to obtain a pre-mixture;

[0068] (2) Then put the obtained mixture into a twin-screw extruder for melt mixing, and extrude and granulate to obtain a polycarbonate / ABS composition; wherein the melting temperature of the twin-screw extruder is 250°C, and the screw speed is 600rpm / min.

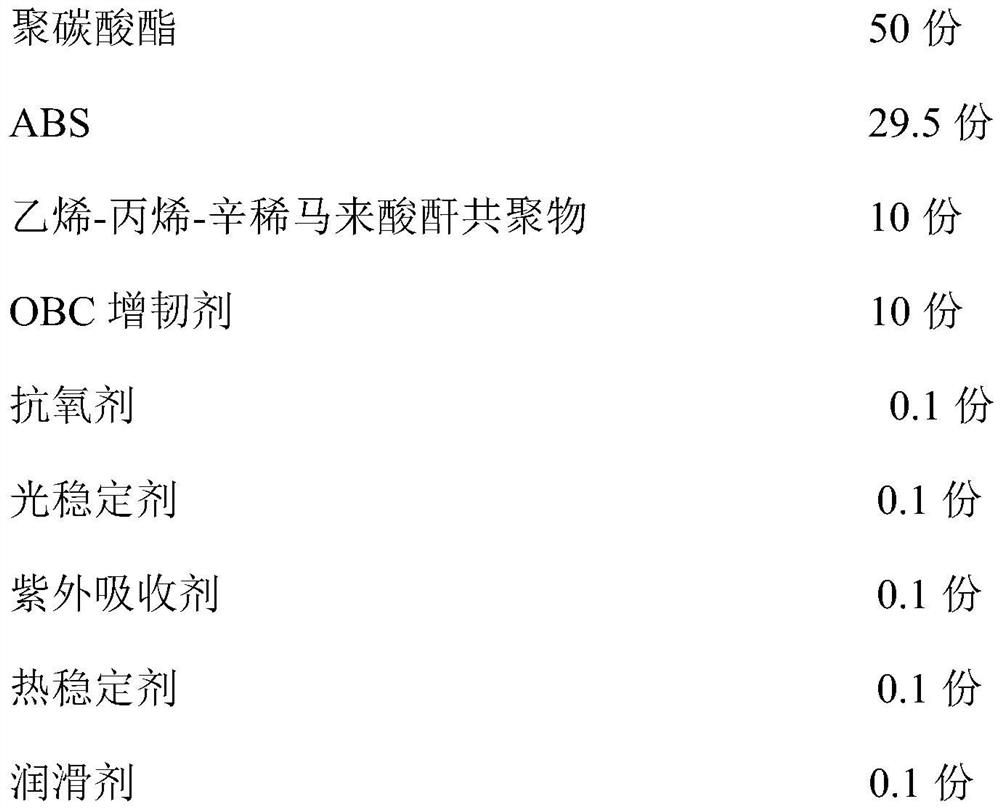

Embodiment 2

[0070] The polycarbonate / ABS composition provided by the present embodiment comprises the following components in parts by weight:

[0071]

[0072] Preparation:

[0073] (1) Polycarbonate, ABS resin and ethylene-propylene-octene maleic anhydride copolymer, OBC toughening agent, antioxidant, light stabilizer, ultraviolet absorber, heat stabilizer, and lubricant are mixed Blending in the machine until uniform to obtain a pre-mixture;

[0074] (2) Then put the obtained mixture into a twin-screw extruder for melting and mixing, and extrude and granulate to obtain a polycarbonate / ABS composition; wherein the melting temperature of the twin-screw extruder is 210° C., and the screw speed is 400 rpm / min.

Embodiment 3

[0076] The polycarbonate / ABS composition provided by the present embodiment comprises the following components in parts by weight:

[0077]

[0078]

[0079] Preparation:

[0080] (1) Polycarbonate, ABS resin and ethylene-propylene-octene maleic anhydride copolymer, antioxidant, light stabilizer, ultraviolet absorber, heat stabilizer, and lubricant are blended in a mixer until uniform, to obtain a premix;

[0081] (2) Then put the obtained mixture into a twin-screw extruder for melt mixing, and extrude and granulate to obtain a polycarbonate / ABS composition; wherein the melting temperature of the twin-screw extruder is 280°C, and the screw speed is 700rpm / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com