Hydrogenation reactor, hydrogenation reaction device and catalytic hydrogenation process

A hydrogenation reactor and catalytic hydrogenation technology, which is applied in the field of catalytic hydrogenation process, hydrogenation reactor, and hydrogenation reaction device, can solve the problems of large reaction device space, unfavorable industrial production, complicated washing process, etc., and achieve saving Space, conducive to industrial production, and simple washing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

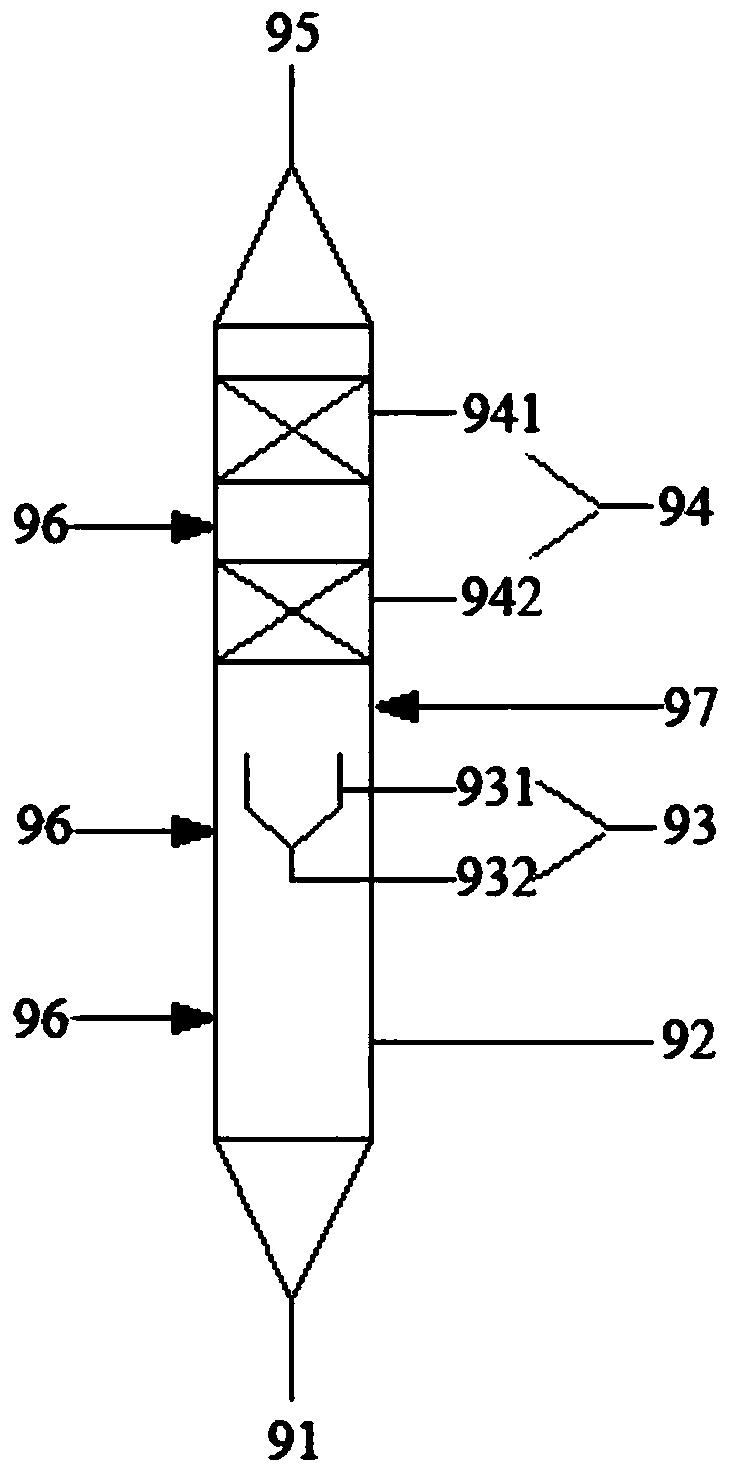

[0071] This embodiment provides a hydrogenation reactor, such as figure 1 As shown, the hydrogenation reactor 9 is a bottom feed, top and side wall discharge structure, the bottom of the hydrogenation reactor 9 is provided with a feed port 91, the lower part is provided with a suspension bed reaction section 92, and the upper part is provided with a suspension bed reaction section 92. There is a fixed bed reaction section 94, a separation section 93 is arranged between the suspension bed reaction section 92 and the fixed bed reaction section 94, and the top of the hydrogenation reactor 9 is provided with a gas phase outlet 95; the middle part of the suspension bed reaction section 92 The side walls in the middle of the separation section 93 are respectively provided with a cold hydrogen injection port. A first washing liquid injection port 97 is provided on the side wall between the fixed bed reaction section 94 and the separation section 93 .

[0072] The separation section ...

Embodiment 2

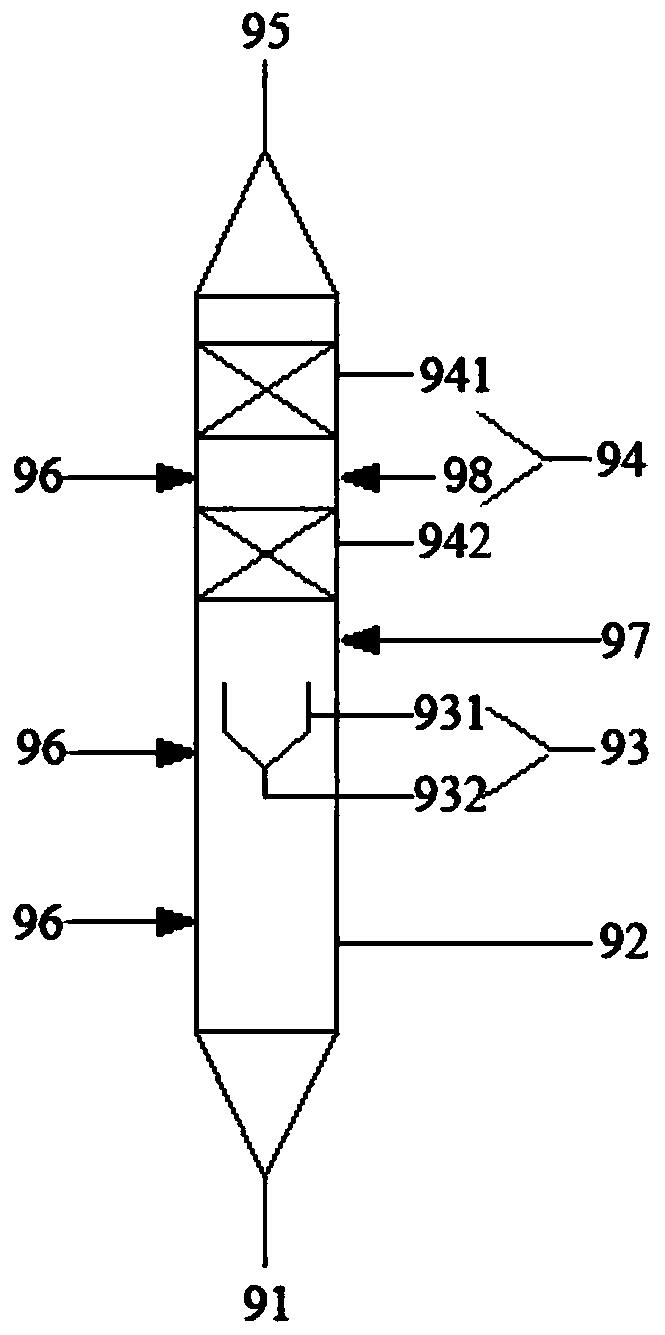

[0077] This embodiment provides a hydrogenation reactor, such as figure 2 As shown, the hydrogenation reactor 9 is a bottom feed, top and side wall discharge structure, the bottom of the hydrogenation reactor 9 is provided with a feed port 91, the lower part is provided with a suspension bed reaction section 92, and the upper part is provided with a suspension bed reaction section 92. There is a fixed bed reaction section 94, a separation section 93 is arranged between the suspension bed reaction section 92 and the fixed bed reaction section 94, and the top of the hydrogenation reactor 9 is provided with a gas phase outlet 95; the middle part of the suspension bed reaction section 92 The side walls in the middle of the separation section 93 are respectively provided with a cold hydrogen injection port. A first washing liquid injection port 97 is provided on the side wall between the fixed bed reaction section 94 and the separation section 93 .

[0078] The separation section...

Embodiment 3

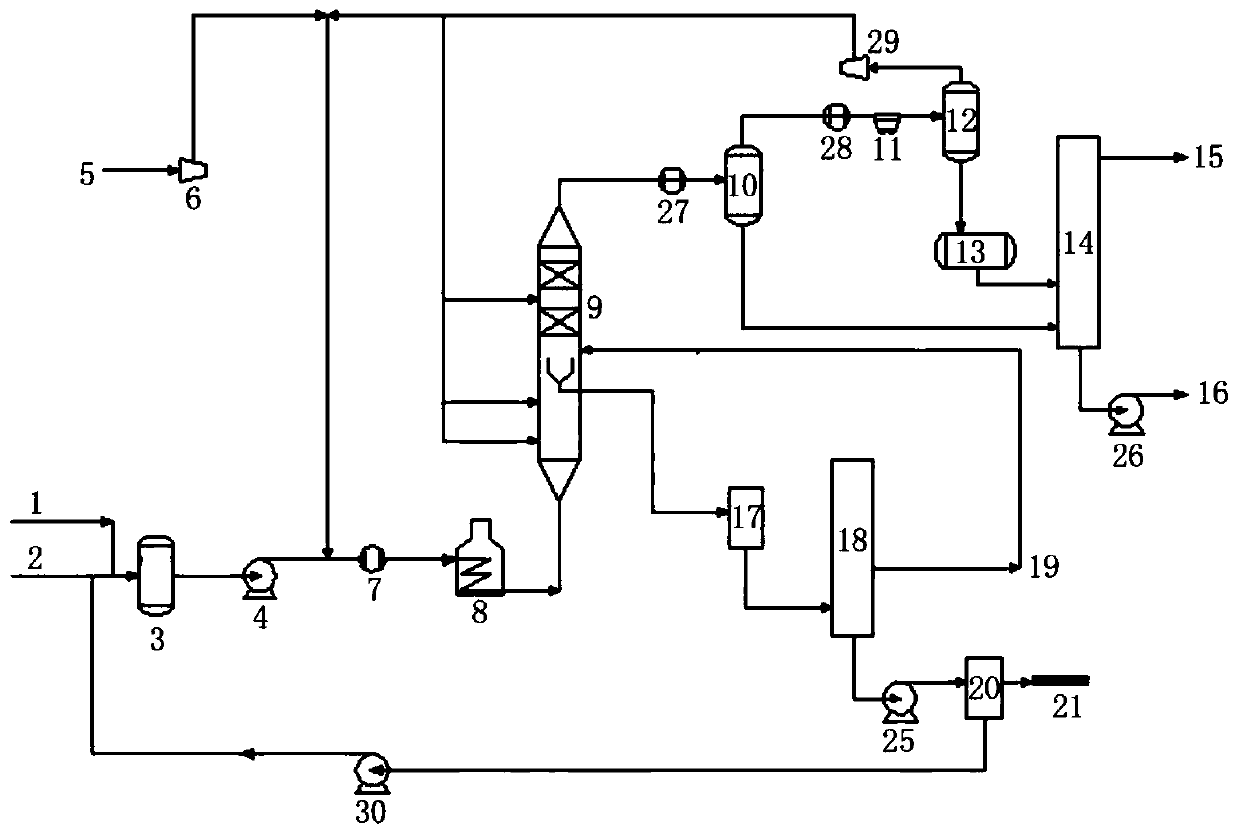

[0083] This embodiment provides a hydrogenation reaction device, such as image 3 As shown, the hydrogenation reaction device includes: the hydrogenation reactor 9 described in Example 1;

[0084] The feed unit includes a raw material tank 3, the outlet of the raw material tank 3 is communicated with the inlet of the first heat exchanger 7 through the first high-pressure pump 4, and the outlet of the first heat exchanger 7 is reacted with hydrogenation through a heating device 8 heating furnace The feed port at the bottom of the device 9 is communicated; the inlet of the first heat exchanger 7 is communicated with the compressor 6;

[0085] Hot low-pressure separator 17, and the first washing liquid injection port 97 decompression column 18 that is communicated with the bottom outlet of hot low-pressure separator 17; The liquid pipe 932 is communicated; the gas oil fraction outlet is provided on the decompression tower 18, and the outlet is communicated with the first washing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com