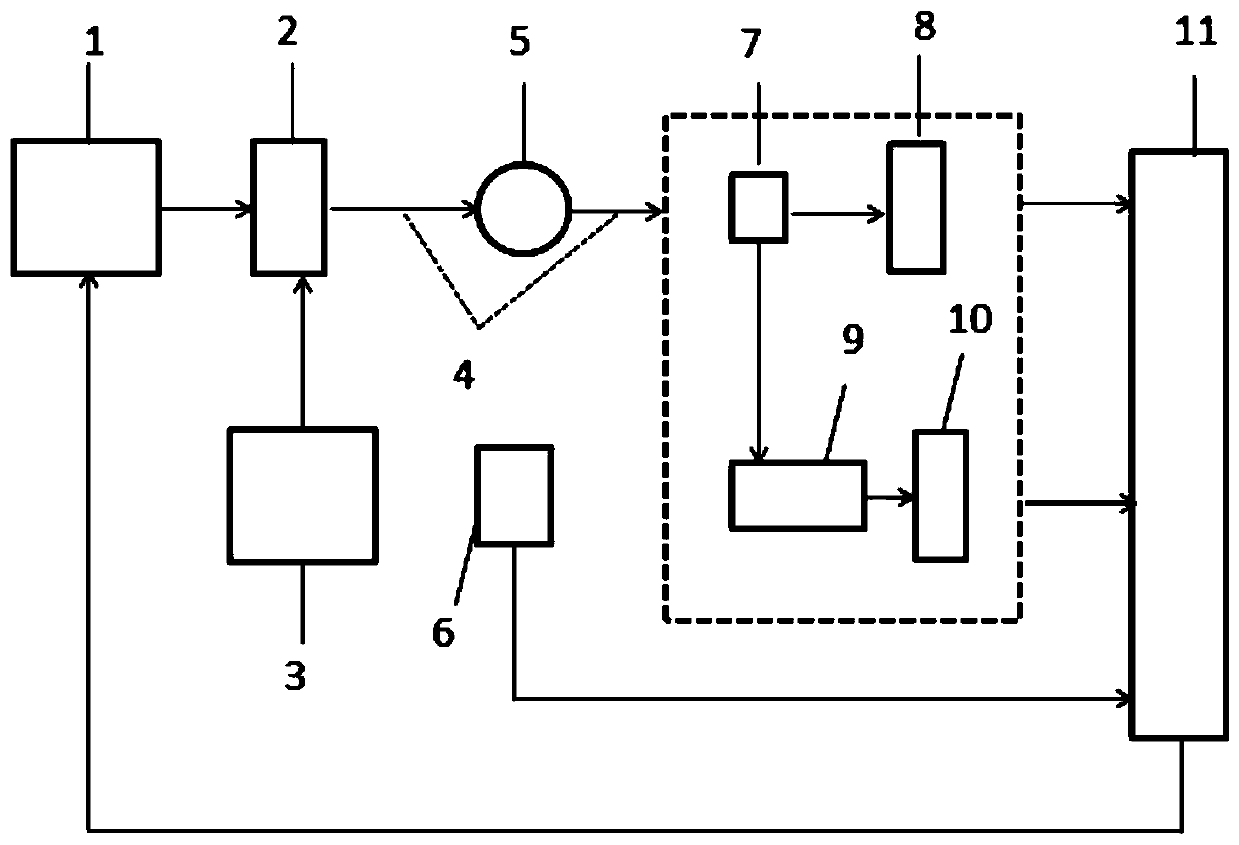

Integrated optical fiber gas detection system and method

A gas detection system and integrated technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of destroying the structure of the gas chamber to be measured, complex manufacturing process, etc., achieving the effect of small size, enhanced mechanical stability, and easy integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] The signal source driving module 1 generates low-frequency scanning signals and high-frequency modulation signals with amplitudes ranging from low to high; the low-frequency scanning signals and high-frequency modulation signals are superimposed and converted into constant current source outputs with small to large currents, and the constant current source drives the laser 2 The laser beam is emitted, and the wavelength of the laser beam can cover the absorption spectrum of the gas to be measured; at the same time, in order to prevent the wavelength of the output laser beam from being affected by temperature, a temperature control module 3 is added to ensure the stability of the output wavelength of the laser beam; the generated laser beam will be It will be directly transmitted to the gas chamber 5 to be tested through the optical fiber 4. The gas chamber 5 has a built-in collimator and mirror to improve the optical coupling efficiency and increase the effective optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com