TBM high-pressure pulsed water-jet rock breaking hypocenter advanced detection device and method thereof

A high-voltage pulse, advanced detection technology, applied in measurement devices, seismic surveys, seismology, etc., can solve problems such as spatial positioning of unfavorable geological bodies, affecting construction progress, and tedious installation, achieving good application prospects, improving accuracy, and detecting Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

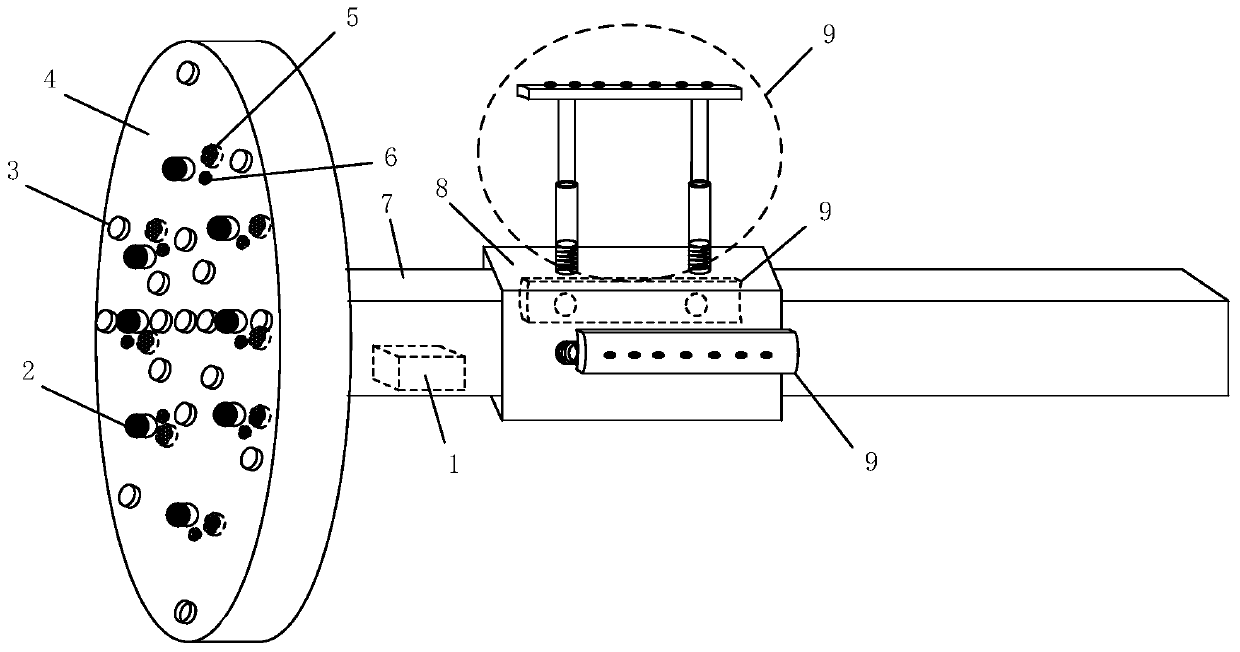

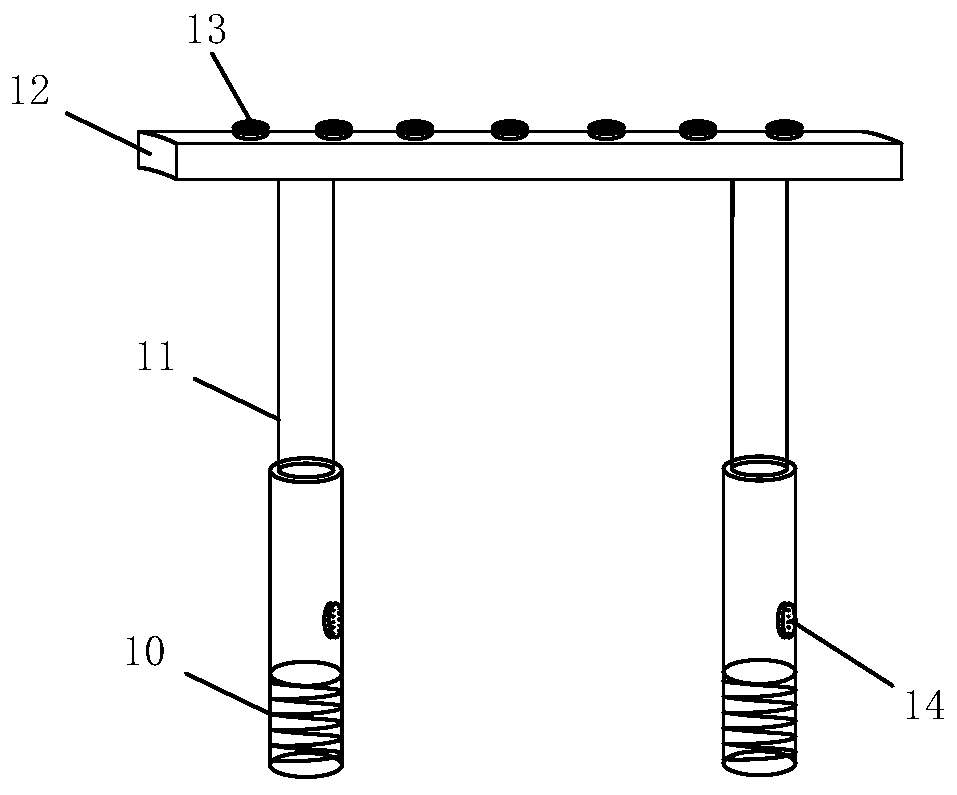

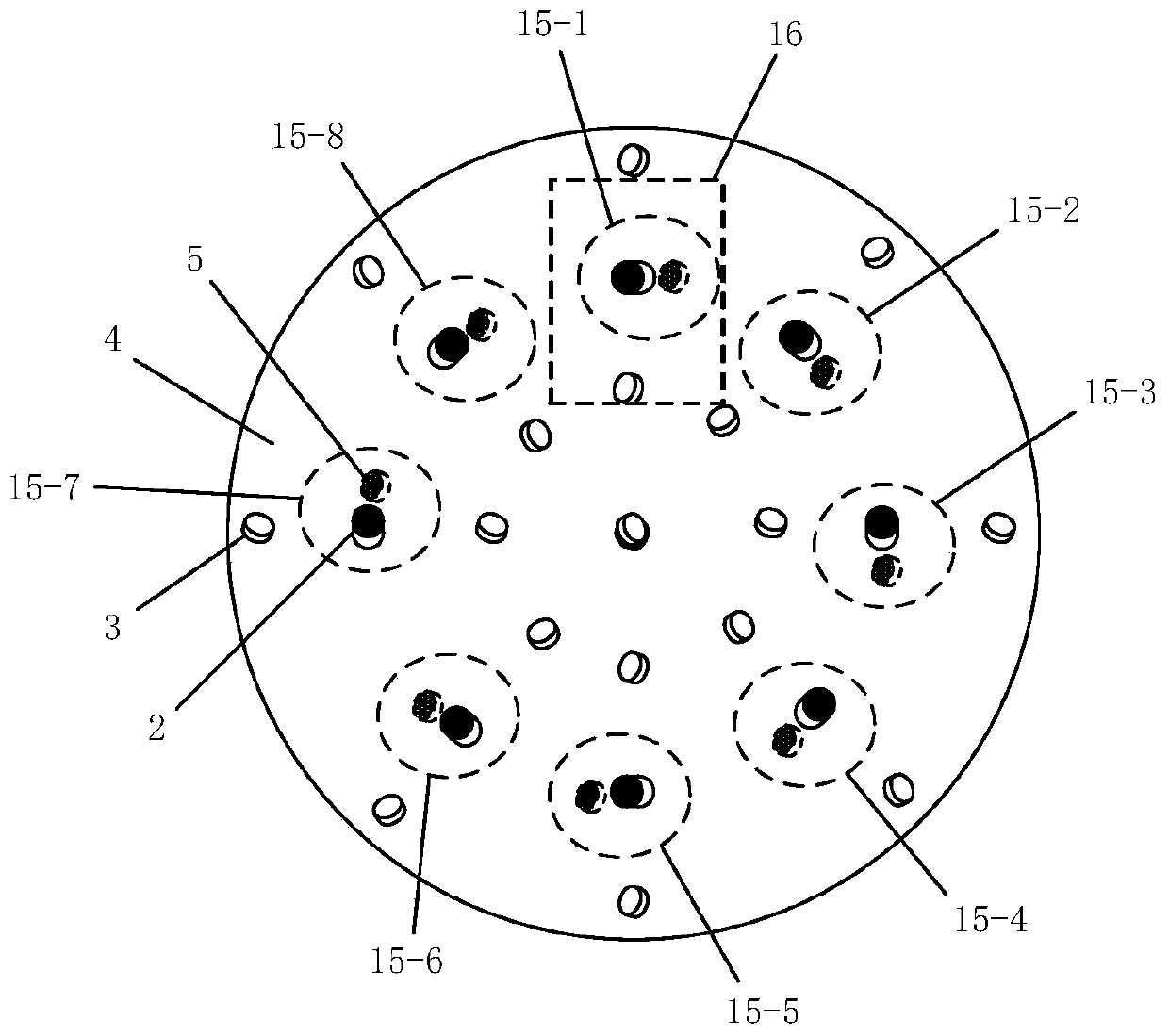

[0042] See Figure 1 to Figure 4 , an embodiment of the present invention provides a TBM high-pressure pulse water jet rock breaking seismic source advanced detection device, including a high-pressure pulse water jet system 1, a nozzle 2, a source sensor 5, a support device 9, a receiving sensor 13, a noise sensor and a data acquisition instrument .

[0043] The high-pressure pulsed water jet system 1 is mounted on a TBM ( figure 1 Only the inner frame 7, the outer frame 8 and the cutter head 4) of the TBM are shown in the figure. The nozzle 2 is installed on the side of the cutter head 4 facing the working surface, and is connected to the outlet of the high-pressure pulse water jet system 1. The nozzles are connected to spray high-pressure pulsed wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com