Optical fiber conduction green light source and all-fiber laser backlight source device

A light source device and optical fiber technology, which is applied in projection devices, optical waveguide coupling, optics, etc., can solve the problems of small blue light penetration depth, temperature quenching, concentration quenching, etc., and achieve enhanced blue light utilization, increased absorption, The effect of low difficulty of heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

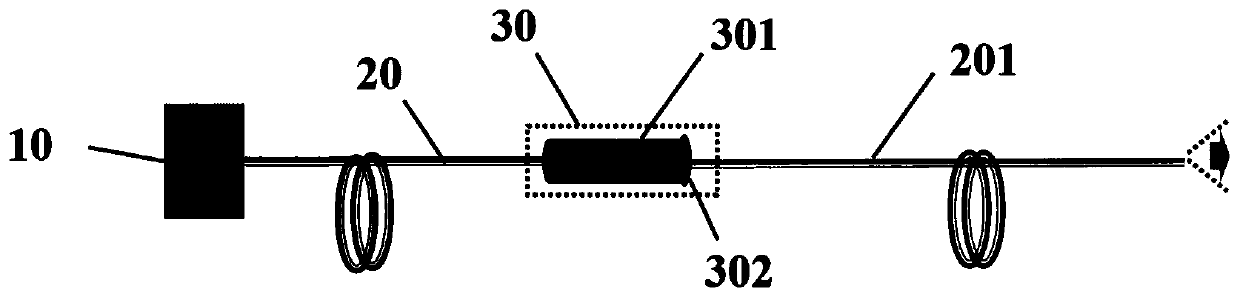

[0026] A kind of optical fiber transmission green light source device, such as figure 1 As shown, it includes blue laser one 10, optical fiber one 20, fluorescent converter 30 and optical fiber two 201 connected in sequence. The fluorescent converter 30 includes a transparent fluorescent ceramic rod 301 and a coupling focusing lens 302, and the coupling focusing lens 302 is located at The transparent fluorescent ceramic rod 301 is connected to one end of the second optical fiber 201 .

[0027] The transparent fluorescent ceramic rod 301 is cerium-doped lutetium aluminum garnet (Ce:Lu 3 Al 5 o 12 , Ce:LuAG) transparent ceramics, Ce 3+ The doping concentration is 0.01 at%, and the transmittance of the transparent ceramic in the green light band is 60.0%. The transparent fluorescent ceramic rod 301 is cylindrical, with an end radius of 0.5 mm and a length of 6.0 mm. For the preparation of transparent ceramics, refer to the preparation process disclosed in patent application C...

Embodiment 2

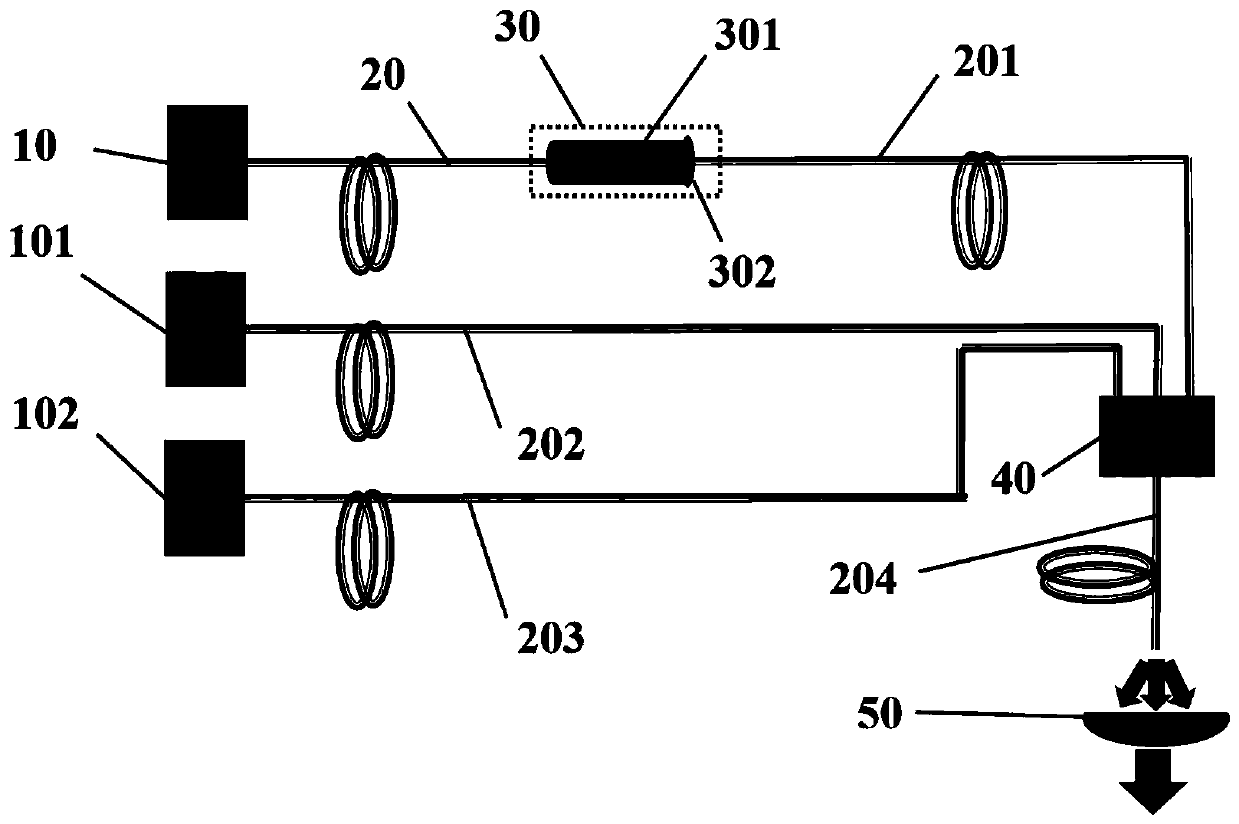

[0030] An all-fiber laser backlight device, such as figure 2 As shown, including the fiber-optic transmission green light source device of embodiment 1, blue laser 2 101, red laser 102, optical fiber 3 202, optical fiber 4 203, optical fiber 5 204, optical fiber beam combiner 40, focusing and collimating mirror 50, all The blue laser 2 101 is connected to the optical fiber 3 202, the red laser 102 is connected to the optical fiber 4 203, the optical fiber 201, the optical fiber 3 202, and the optical fiber 203 of the green light source device are combined and inserted into the optical fiber combiner 40, The other end of the optical fiber combiner 40 outputs the optical fiber five 204 , and the focusing and collimating mirror 50 is installed at the end of the optical fiber five 204 .

[0031]When the output power of the blue laser-10 is 2W, the operating temperature of the transparent fluorescent ceramic rod 301 is 70°C; the end can obtain 300lm green light, and the luminous e...

Embodiment 3

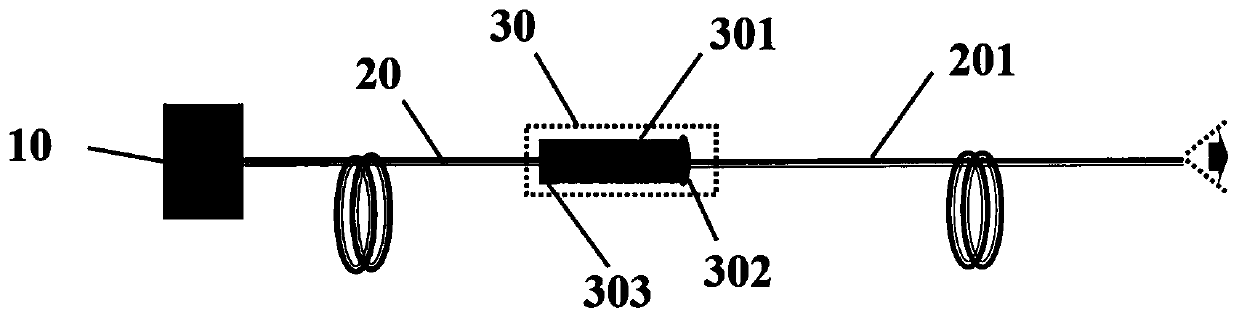

[0034] A kind of optical fiber transmission green light source device, such as image 3 As shown, it includes blue laser one 10, optical fiber one 20, fluorescent converter 30 and optical fiber two 201 connected in sequence. The fluorescent converter 30 includes a transparent fluorescent ceramic rod 301, a coupling focusing lens 302 and a dichroic film 303. The coupling The focusing lens 302 is located at one end of the transparent fluorescent ceramic rod 301 connected to the second optical fiber 201 , and the dichroic film 303 is located at the end of the transparent fluorescent ceramic rod 301 connected to the first optical fiber 20 .

[0035] The transparent fluorescent ceramic rod 301 is cerium-doped lutetium aluminum garnet (Ce:Lu 3 Al 5 o 12 , Ce:LuAG) transparent ceramics, Ce 3+ The doping concentration is 0.50 at%, and the transmittance of the transparent ceramic in the green light band is 80.0%. The transparent fluorescent ceramic rod 301 is cylindrical, with an en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| luminous efficiency | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com