Cathode catalyst layer structure capable of enhancing catalyst durability and preparation method thereof

A cathode catalysis and catalyst technology, which is applied to structural parts, battery electrodes, electrical components, etc., can solve the problems of increased catalyst attenuation, reduced effective specific surface area of catalysts, and loss of platinum mass, achieving enhanced durability and reduced ECSA and the effect of platinum mass loss on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0042] One, embodiment 1-3, comparative example 1-2

Embodiment 1

[0044] A cathode catalytic layer structure that strengthens catalyst durability, and its preparation method includes the following steps: A, configuring slurry containing different catalyst particle sizes; B, gradually electrospraying and drying the slurry containing catalysts with different particle sizes and different loads to On the proton membrane or diffusion layer, or first electrospray it on polytetrafluoroethylene PTFE and then transfer it multiple times to obtain a cathode catalytic layer structure that strengthens the durability of the catalyst, including the first catalytic part, the second catalytic part, and the second catalytic part. Three catalytic parts, the first catalytic part, the second catalytic part and the third catalytic part are arranged in sequence from the area near the diffusion layer to the area near the proton exchange membrane; the first catalytic part, the second catalytic part and the third catalytic part are built-in There is a pure Pt catalyst...

Embodiment 2

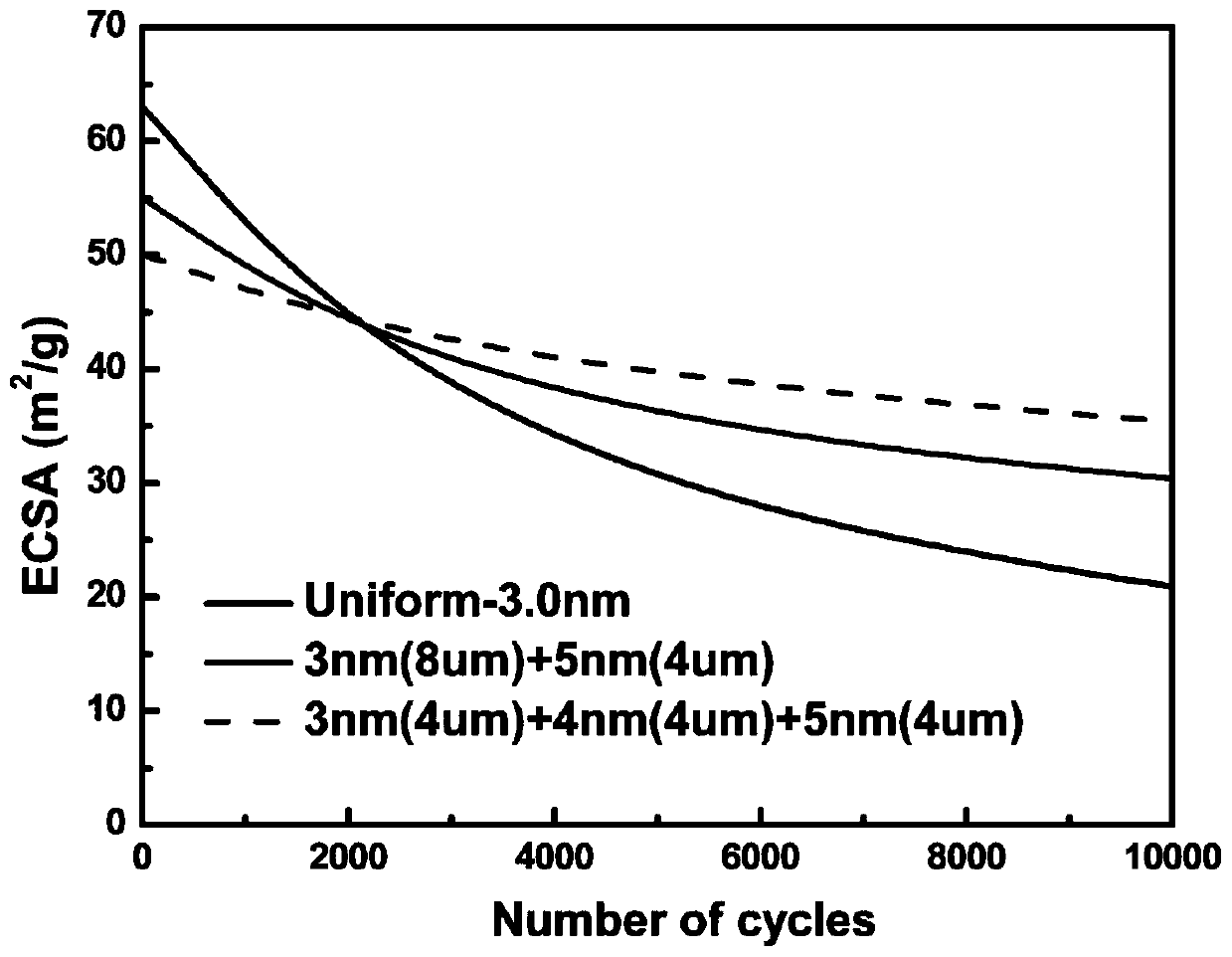

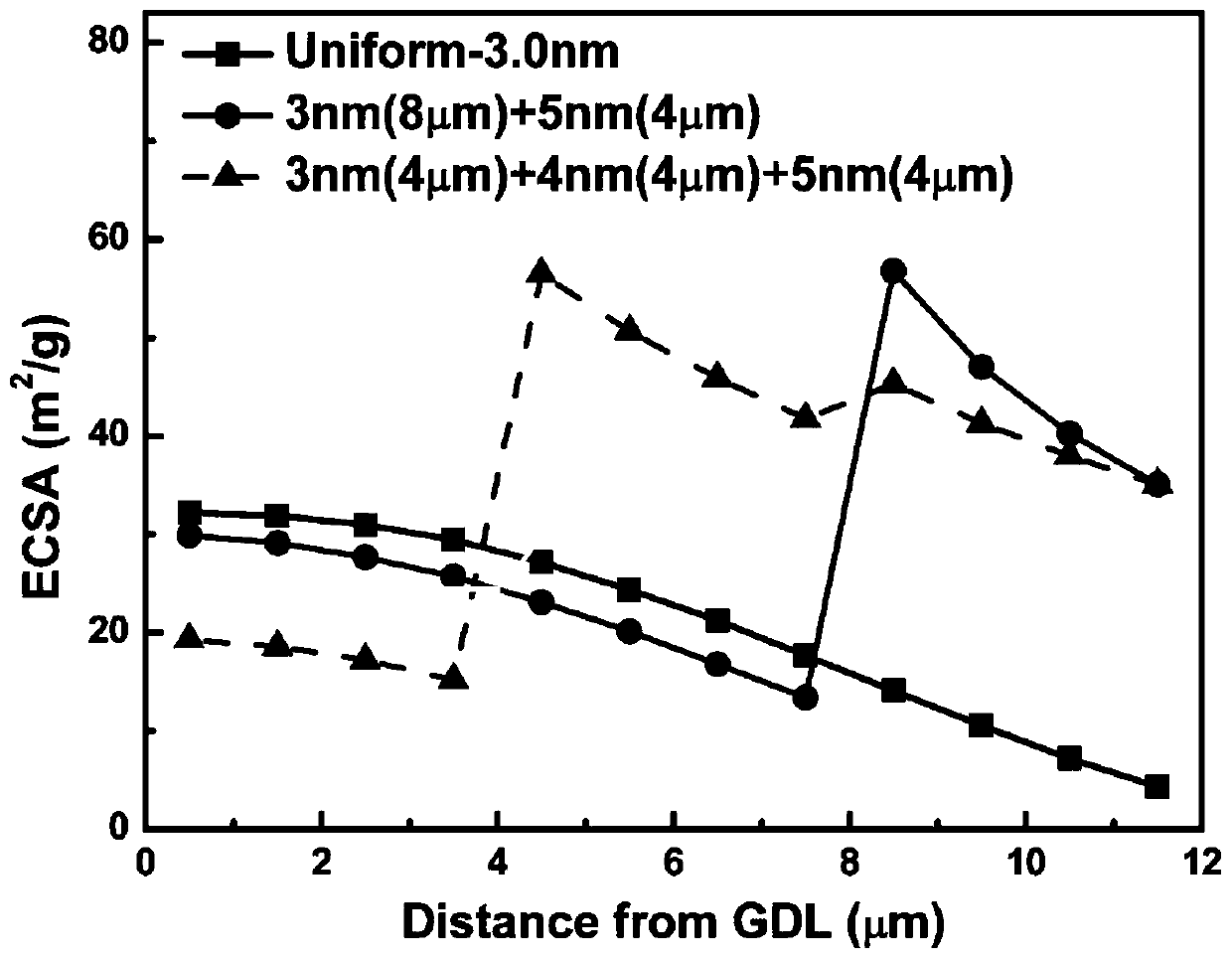

[0047] Based on the fact that the traditional cathode catalytic layer will have obvious activity loss during the long-term operation of the fuel cell, especially on the side close to the proton exchange membrane, this embodiment proposes a cathode catalytic layer structure that enhances the durability of the catalyst. Including the first catalytic part, the second catalytic part and the third catalytic part, the first catalytic part, the second catalytic part and the third catalytic part are arranged in order from the area near the diffusion layer to the area near the proton exchange membrane; the first catalytic The first, second and third catalytic parts are built with pure Pt catalysts, and the gradient cathode catalytic layer with larger average particle size and lower platinum loading is used on the side close to the proton exchange membrane.

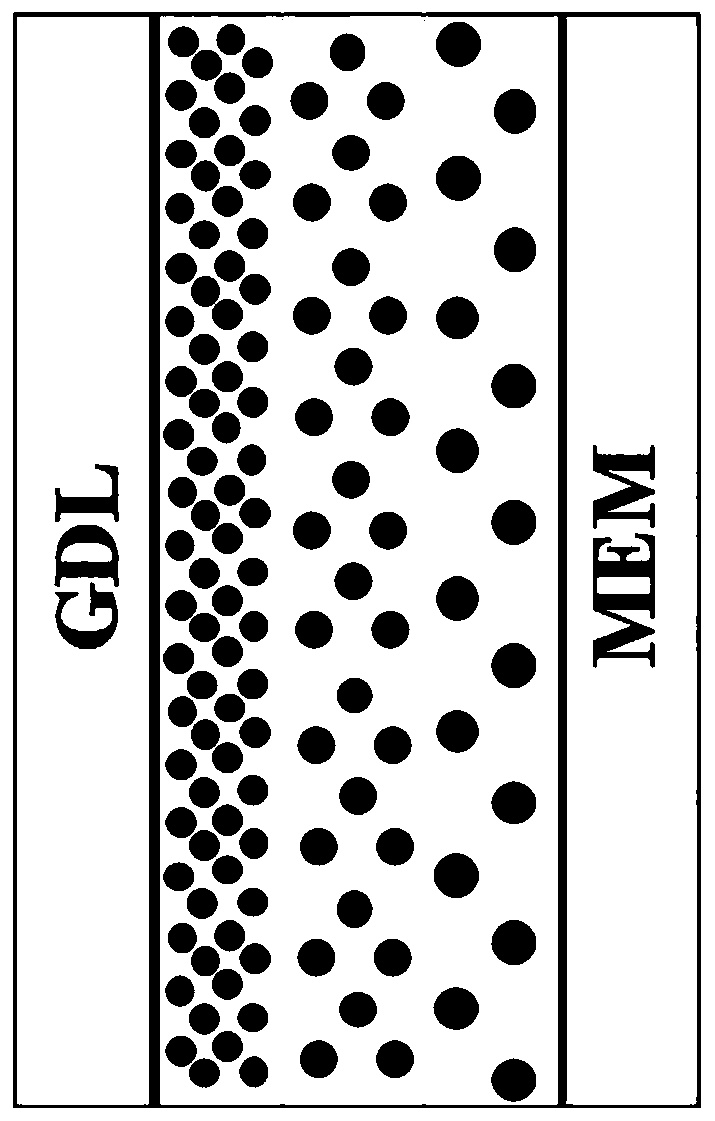

[0048] Such as figure 1 As shown, the average particle diameter of the catalyst particles in the third catalytic section close t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com