Heater member, heater tape, and molded body equipped with heater member

A technology for heaters and molded bodies, applied in the direction of heating elements, heating element materials, ohmic resistance heating parts, etc., can solve the problem of low adhesion of conductive transparent films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Indium tin oxide (ITO) (tin oxide Concentration: 10% by weight) as a target, the magnetic flux density of the horizontal magnetic field at the surface of the target is 100mT (milliTesla) in the presence of a high magnetic field and an inert gas by DC magnetron sputtering method to form an ITO film. The PEN thin film formed with the ITO film was left in the air at 150° C. for 3 hours to perform annealing treatment. Thereby, ITO is crystallized, and a transparent conductive film is formed. The thickness of the transparent conductive film was 115 nm. The transparent conductive film obtained by the annealing treatment has a polycrystalline structure.

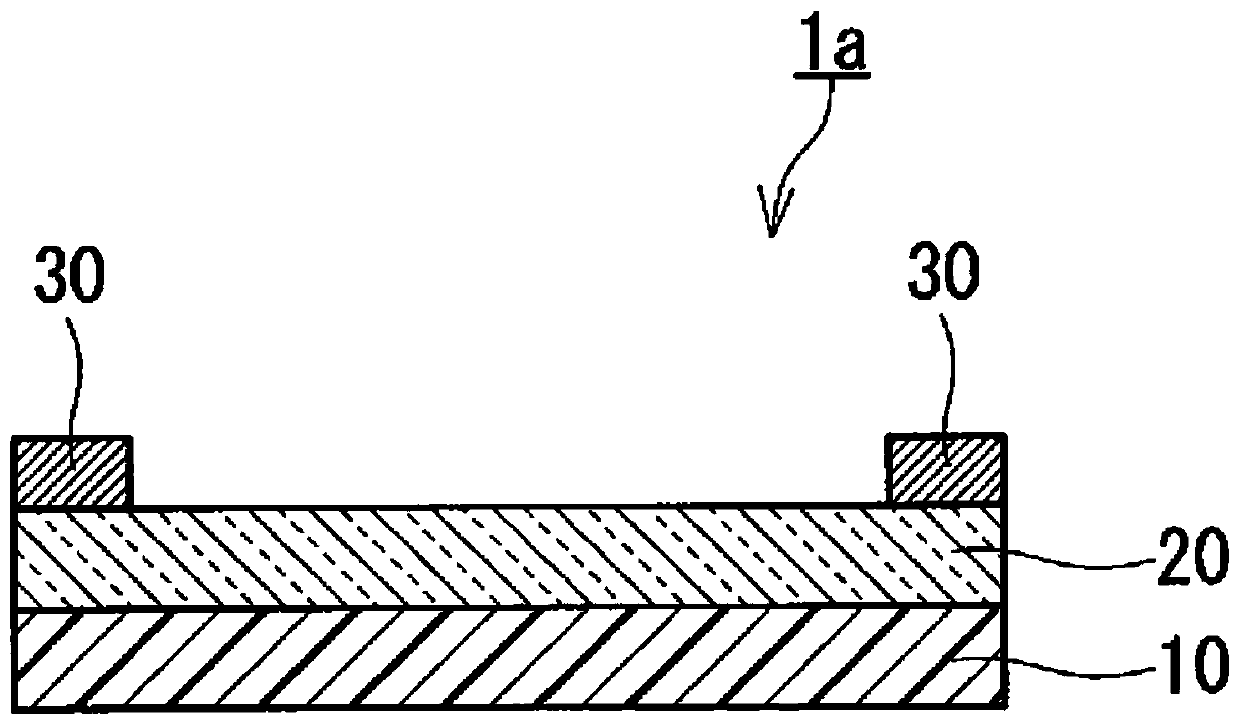

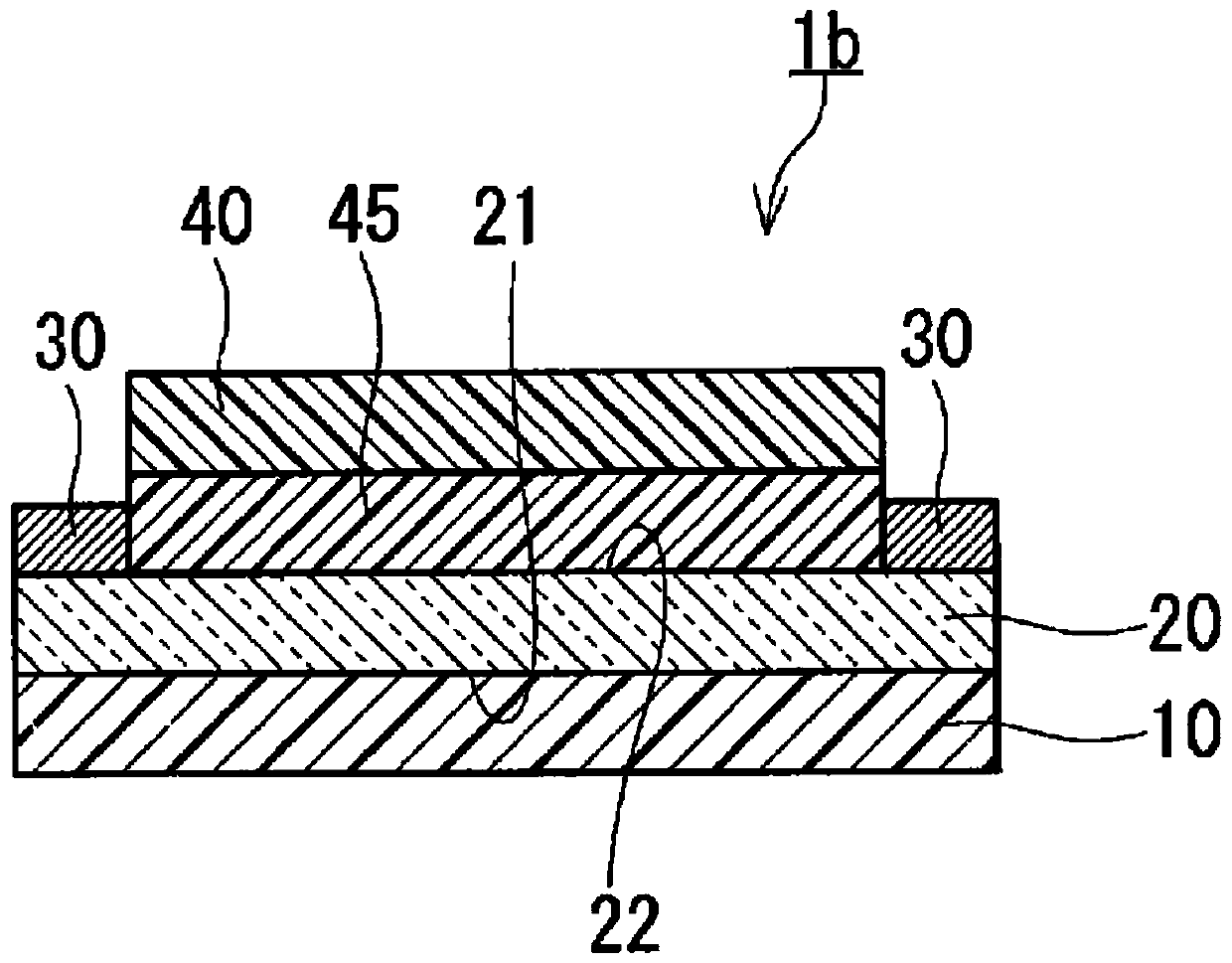

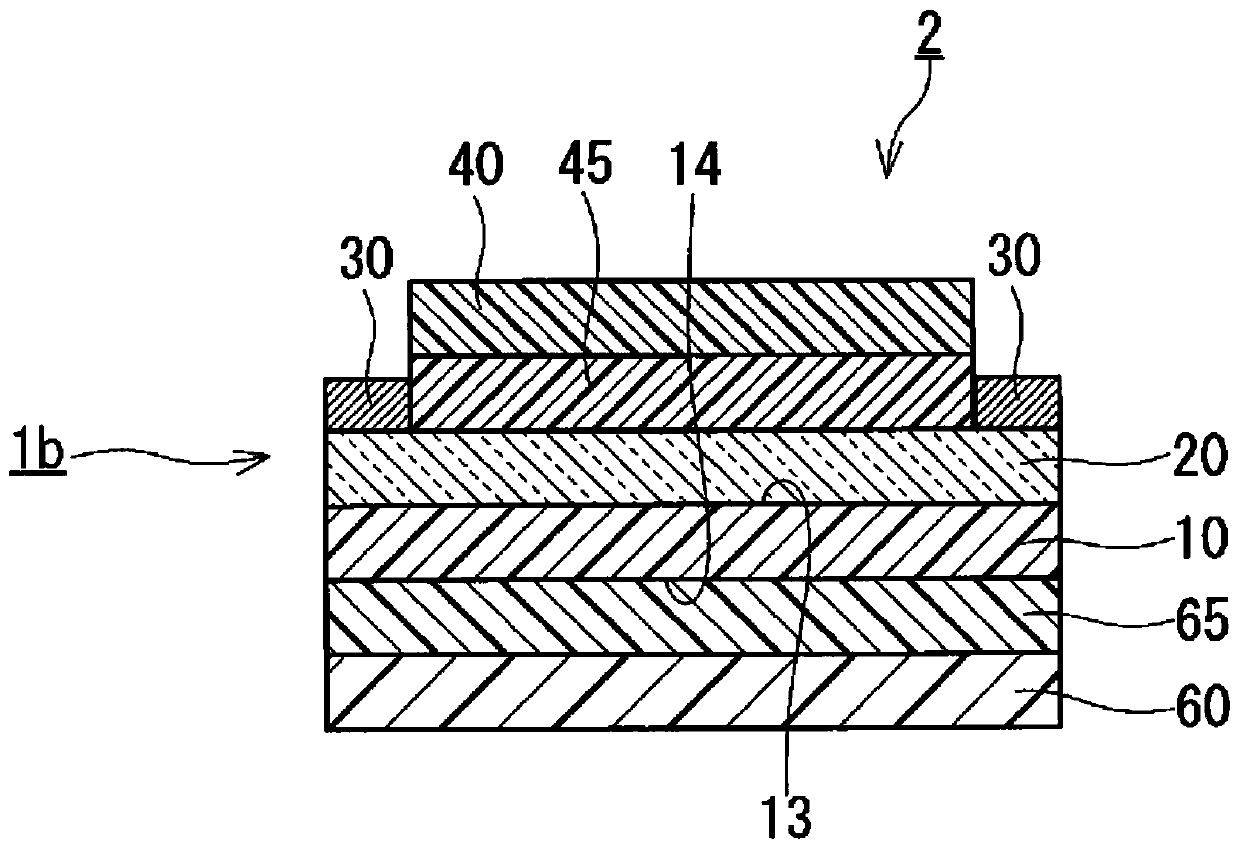

[0095] Next, the PEN film on which the transparent conductive film was formed was cut into strips (short side: 30 mm x long side: 50 mm), and a pair of ends of the transparent conductive film facing each other and extending in the longitudinal direction were exposed with a mask. Cover part of the transparent conductive fi...

Embodiment 2

[0097] A heater member of Example 2 was produced in the same manner as in Example 1 except that a transparent polyimide film (transparent PI, manufactured by Kolon Industries, Inc.) having a thickness of 50 μm was used instead of the PEN film.

Embodiment 3

[0099] Using a polyimide film (PI, manufactured by Toray-Dupont Co., Ltd., product name: Kapton) having a thickness of 75 μm instead of the PEN film, the same operation as in Example 1 was performed to prepare the heater member of Example 3. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com