Secondary fermentation process of culture material

A technology of secondary fermentation and culture material, applied in horticulture, cultivation, plant cultivation and other directions, can solve the problems of incomplete fermentation, affecting the quality and yield of edible fungi, etc., to avoid slow or ineffective fermentation, shorten the fermentation cycle, and achieve Diversified Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

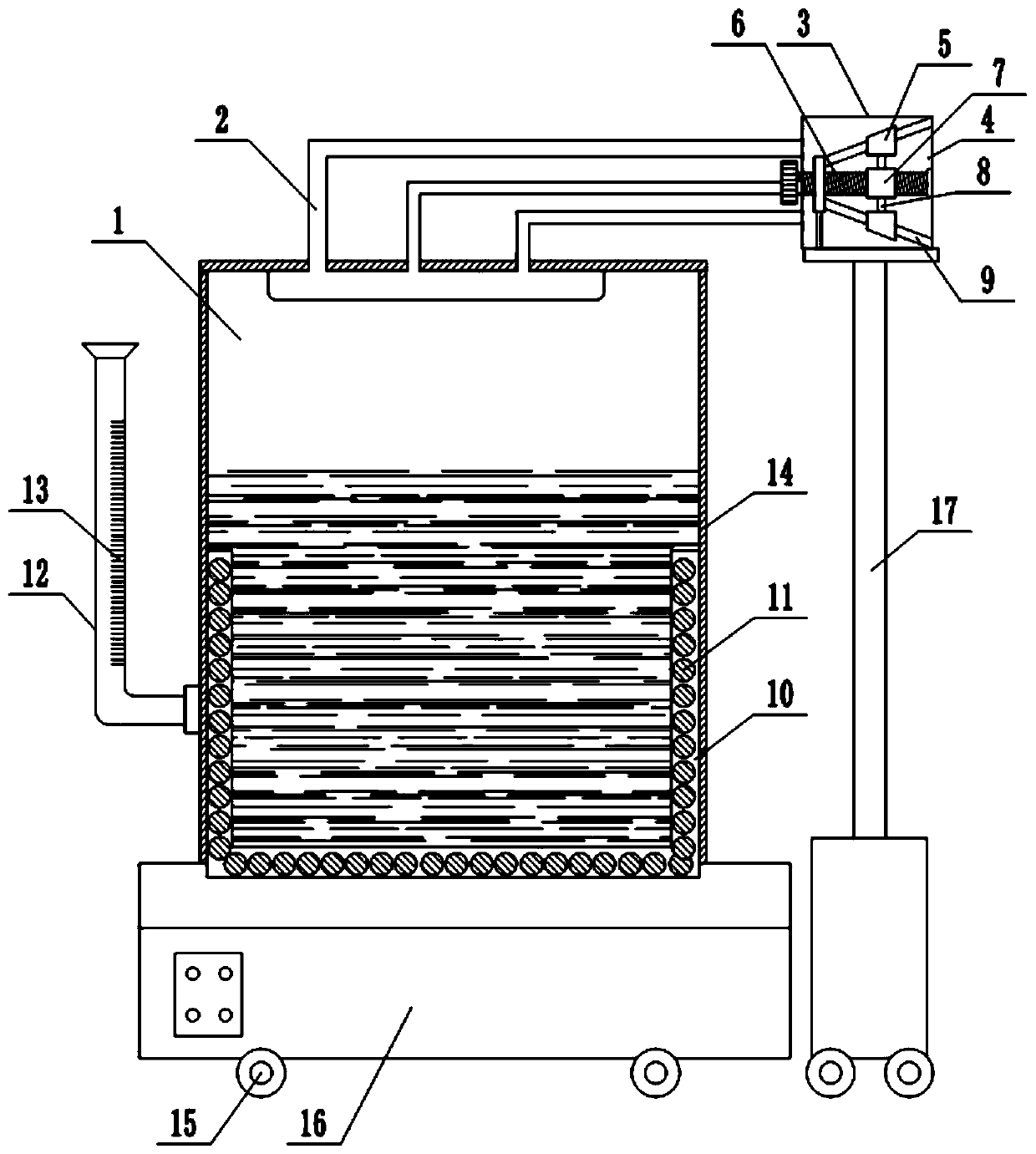

Embodiment 1

[0040] The specific steps for fermenting edible mushroom culture material by adopting culture material secondary fermentation process of the present invention are as follows:

[0041] Step I: preparation of compost, the raw materials of compost include 2000kg of wheat straw, 250kg of cake, 10kg of animal excrement, 75kg of superphosphate, 30kg of urea, 75kg of gypsum, 75kg of limestone and 10kg of fungicide. Feces need to be collected in advance, dried in the sun, crushed and stored for use before use (in the actual batching, the raw materials can be properly adjusted according to actual needs);

[0042] Step II: pre-fermentation, the pre-fermentation process comprises the steps:

[0043] (1) Pre-wetting and pre-stacking of raw materials: pre-stacking of forage and animal manure after pre-wetting;

[0044] (2) Building a heap: choose a place with a higher terrain and close to the mushroom house, and disinfect it with 5% lime water before building the heap; Lay the forage on th...

Embodiment 2

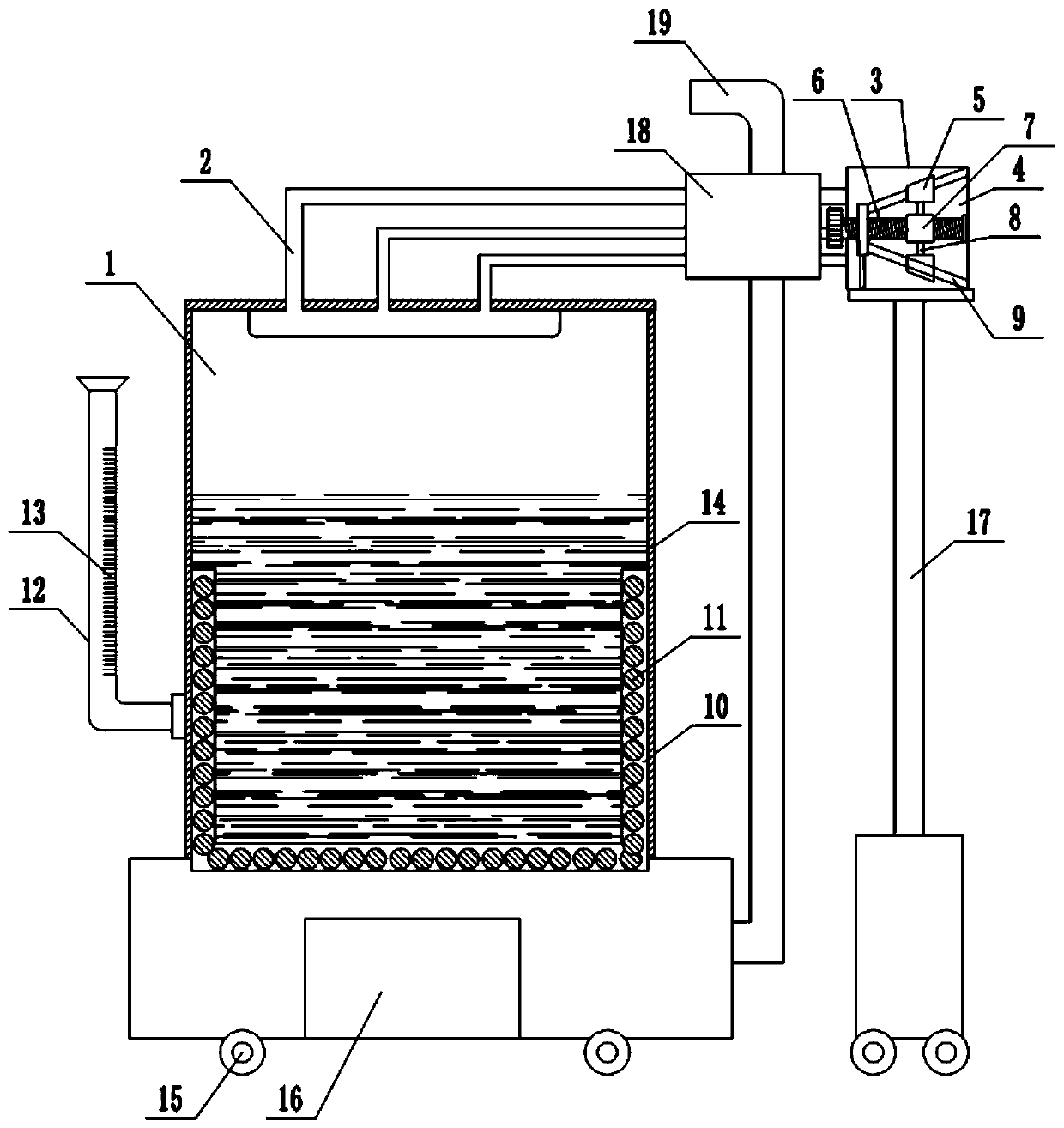

[0062] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, the heating mechanism 16 is a stove heating mechanism 16, and the stove heating mechanism 16 includes a stove with a filling port and a stove for exhausting smoke from the stove. The vertical smoke exhaust passage 19, the steam pipe 2 is covered with a thermal insulation cover 18, and the thermal insulation cover 18 runs through the smoke exhaust passage 19 of the stove heating mechanism 16.

[0063] In this embodiment, heating through the stove breaks the restriction of whether the electricity is on or not, and is not limited by the fuel in the stove. The agricultural waste generated during the cultivation of edible fungi can be reused, realizing a good ecological cycle. . The thermal insulation jacket 18 outside the steam pipe 2 can heat the steam pipe 2 at high temperature. Since the steam enters the steam pipe 2 and the temperature is relatively high, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com