Composite artificial blood vessel and preparation method thereof

An artificial blood vessel and composite technology, applied in the field of artificial blood vessels, can solve the problem that smooth muscle cells and fibroblasts are difficult to infiltrate in large quantities, and achieve the effects of good adhesion, good repeatability, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the above-mentioned artificial blood vessel is: comprising:

[0048] a. Prepare the blended spinning solution of collagen / PLCL, the mass ratio of collagen / PLCL is 50:50 or 25:75, the concentration of spinning solution is 6%-12%, and the solvent is hexafluoroisopropanol;

[0049] b. use the spinning solution prepared in step a to prepare a nanofiber membrane with a thickness of 5-50 microns by electrospinning, and the spinning voltage is 8-20kV;

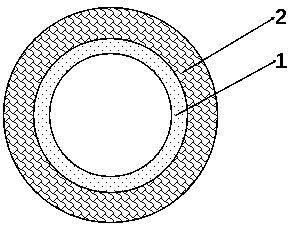

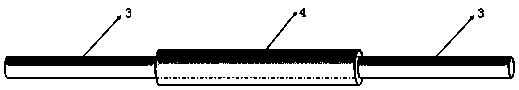

[0050] c. Use the nanofiber membrane prepared in step b to wind a certain number of nanofiber membranes on the stainless steel rod according to the thickness of the first nanofiber layer 1, and prepare the nanofiber layer 1 by hot pressing at 45-55°C;

[0051] d. Prepare PLCL spinning solution, the concentration of spinning solution is 6%-12%, and the solvent is hexafluoroisopropanol;

[0052] e. Use the spinning solution prepared in step d to prepare PLCL nanofiber membranes by electrospinning, then ...

Embodiment 1

[0057] Prepare the spinning solution of collagen / PLCL (caprolactone lactate copolymer) blend, the mass ratio of collagen / PLCL is 50:50, the concentration of spinning solution is 10% w / v, and the solvent is hexafluoroisopropyl alcohol. A nanofiber membrane with a thickness of 10 microns was prepared by electrospinning, and the spinning voltage was 12kV. The prepared nanofiber membrane was wound on a 3.0mm stainless steel rod for 7 layers, and hot-compressed at 50°C. The first nanofiber layer 1, the thickness of the first nanofiber layer 1 is 56 microns.

[0058] Prepare the PLCL spinning solution, the concentration of the spinning solution is 8%, and the solvent is hexafluoroisopropanol. The PLCL nanofiber membrane was prepared by electrospinning, then the PLCL nanofiber membrane was cut into pieces, placed in deionized water, and the fibers were dispersed evenly by a high-speed homogenizer to prepare a nanofiber solution with a concentration of 35%. The solution needs to be ...

Embodiment 2

[0063] A collagen / PLCL blended spinning solution was prepared, the mass ratio of collagen / PLCL was 25:75, the concentration of the spinning solution was 9% w / v, and the solvent was hexafluoroisopropanol. A nanofiber membrane with a thickness of 10 microns was prepared by electrospinning, and the spinning voltage was 12kV. The prepared nanofiber membrane was wound 8 layers on a 4.0mm stainless steel rod, and hot-compressed at 50°C. The thickness of the first nanofiber layer 1 measured by a laser caliper is 62 microns.

[0064] Prepare the PLCL spinning solution, the concentration of the spinning solution is 8%, and the solvent is hexafluoroisopropanol. The PLCL nanofiber membrane was prepared by electrospinning, then the PLCL nanofiber membrane was cut into pieces, placed in deionized water, and the fibers were dispersed evenly by a high-speed homogenizer to prepare a nanofiber solution with a concentration of 40%. The solution needs to be vacuum degassed before use.

[0065]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com