Wide-spectrum extremely-low transmission structure and preparation process thereof

A preparation process and wide-spectrum technology, which is applied in the field of wide-spectrum ultra-low transmission structure and its preparation process, can solve the problems of high stability, low light transmittance, and wide-spectrum ultra-low, achieving remarkable performance, high preparation repeatability, Effects in simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

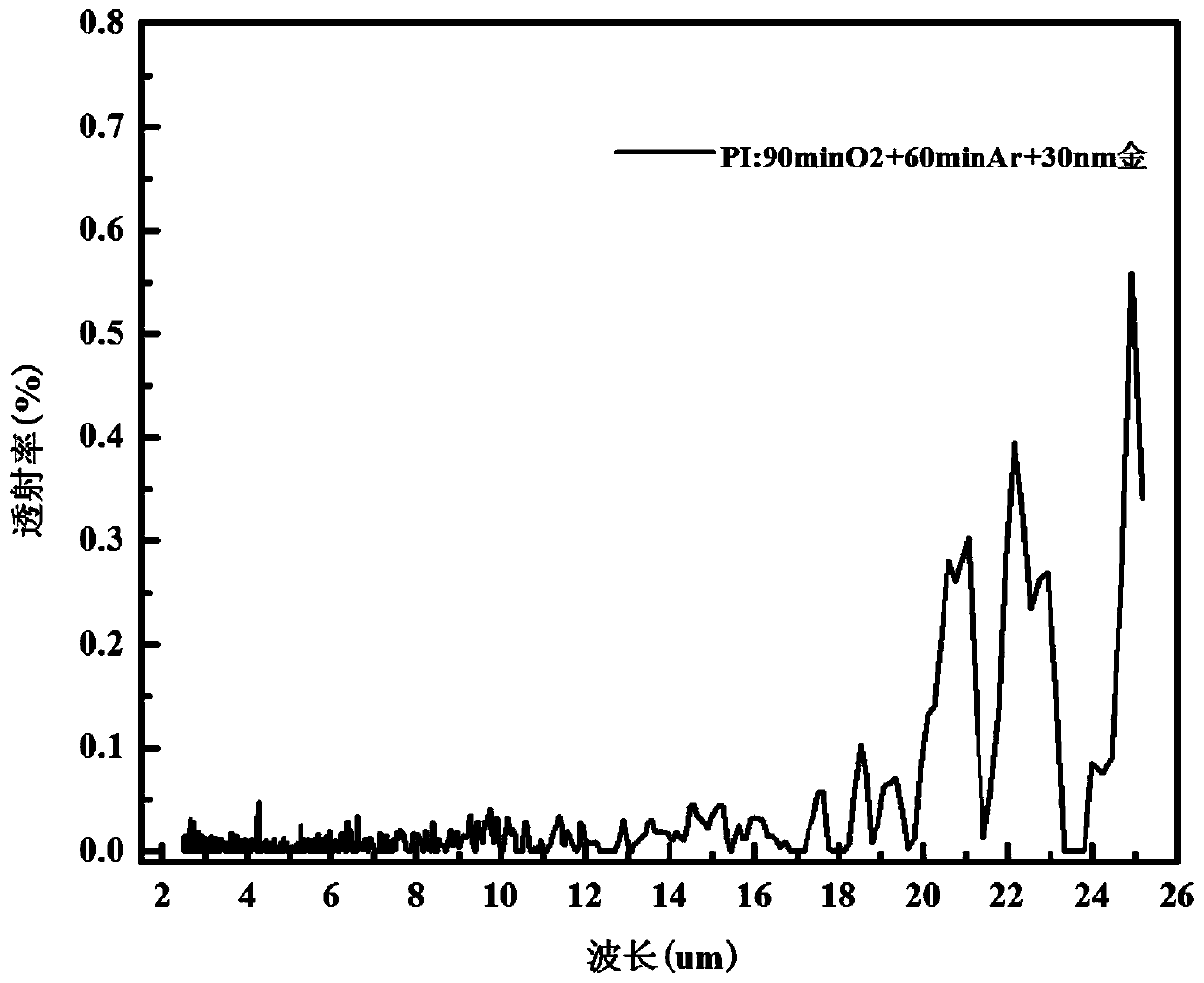

[0039] A wide-spectrum extremely low-transmission structure, including a polymer material substrate, specifically a polyimide material substrate, and a nano-forest structure directly formed on the opposite surfaces of the substrate, and the material loaded on the nano-forest structure is Au metal nanoparticles.

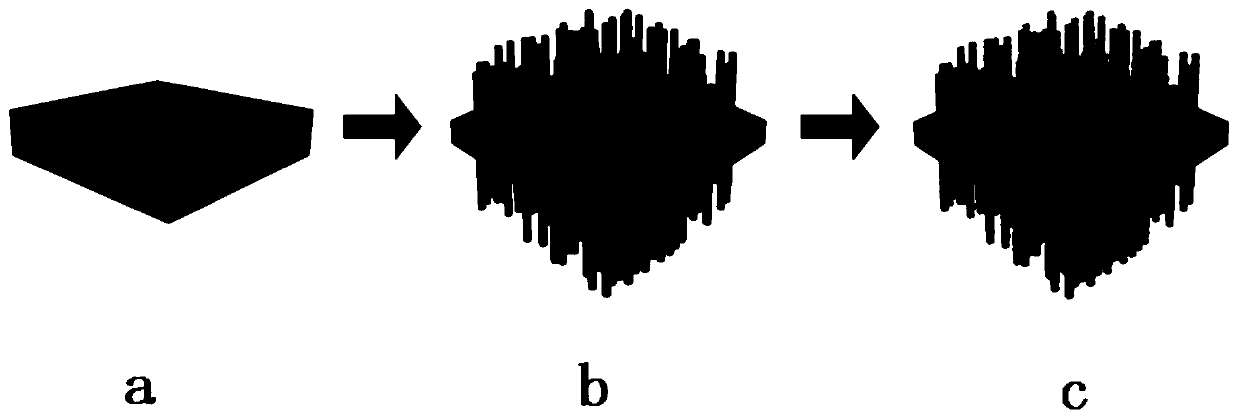

[0040] The preparation process of the above-mentioned wide-spectrum extremely low transmission structure, such as figure 1 As shown, the details are as follows:

[0041] First, prepare the substrate, the structure of which is as follows figure 1 Shown in a; Subsequently, the upper surface of the substrate is bombarded with oxygen plasma, wherein the oxygen flow rate is 30 sccm, the pressure is 2.36 Pa, the power is 75 W, and the bombardment time is 90 min. Subsequently, argon plasma bombardment was carried out, wherein the flow rate of argon gas was 20 sccm, the pressure was 2.4 Pa, the power was 75 W, and the bombardment time was 60 min. After the above treatment,...

Embodiment 2

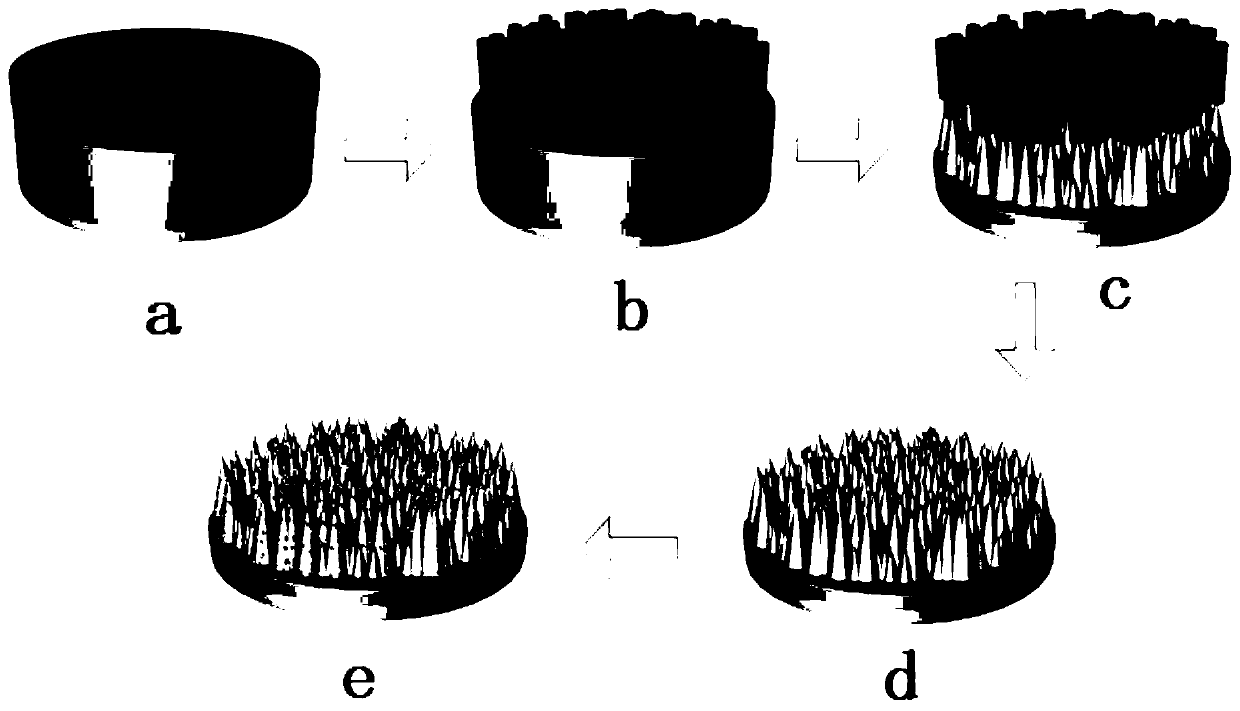

[0045] A wide-spectrum extremely low transmission structure, including a silicon substrate, a nano-forest structure directly formed on one of the surfaces of the substrate, metal nanoparticles loaded on the nano-forest structure and made of Ag, and arranged on the substrate with nano A metal layer on the opposite surface of the forest structure.

[0046] The preparation process of the above wide-spectrum ultra-low transmission structure is as follows: image 3 As shown, after forming a metal layer on one surface of the substrate, the nano-forest structure loaded with metal nanoparticles is formed on the other surface of the substrate; or after the nano-forest structure loaded with metal nanoparticles is formed on the other surface of the substrate , and then form a metal layer on the surface of the substrate. in,

[0047] The process of forming a metal layer on the surface of the substrate is as follows:

[0048] The metal layer is directly formed on the surface of the subs...

Embodiment 3

[0055] A wide-spectrum extremely low transmission structure, including a polymer substrate, the polymer is PMMA or PTFE or PI or PS or PC, directly forming a nano-forest structure on one of the surfaces of the substrate, and loading materials on the nano-forest structure Au metal nanoparticles, and a metal layer disposed on the other surface of the substrate opposite to the nano-forest structure.

[0056] The preparation process of the above wide-spectrum ultra-low transmission structure is as follows: Figure 5 As shown, a metal layer is first formed on one surface of the substrate, and then a nano-forest structure loaded with metal nanoparticles is formed on the other surface of the substrate; or a nano-forest structure loaded with metal nanoparticles is formed on the other surface of the substrate After that, a metal layer is formed on the surface of the substrate.

[0057] The specific process of this embodiment is as follows:

[0058] First sputter a metal layer on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com