Green method for preparing high-carbon-content porous biochar material

A biochar and green technology, applied in carbon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as difficult large-scale application, difficult to remove hydrochloric acid, strong corrosion, etc., to achieve easy large-scale application, low ammonia concentration Low, porosity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

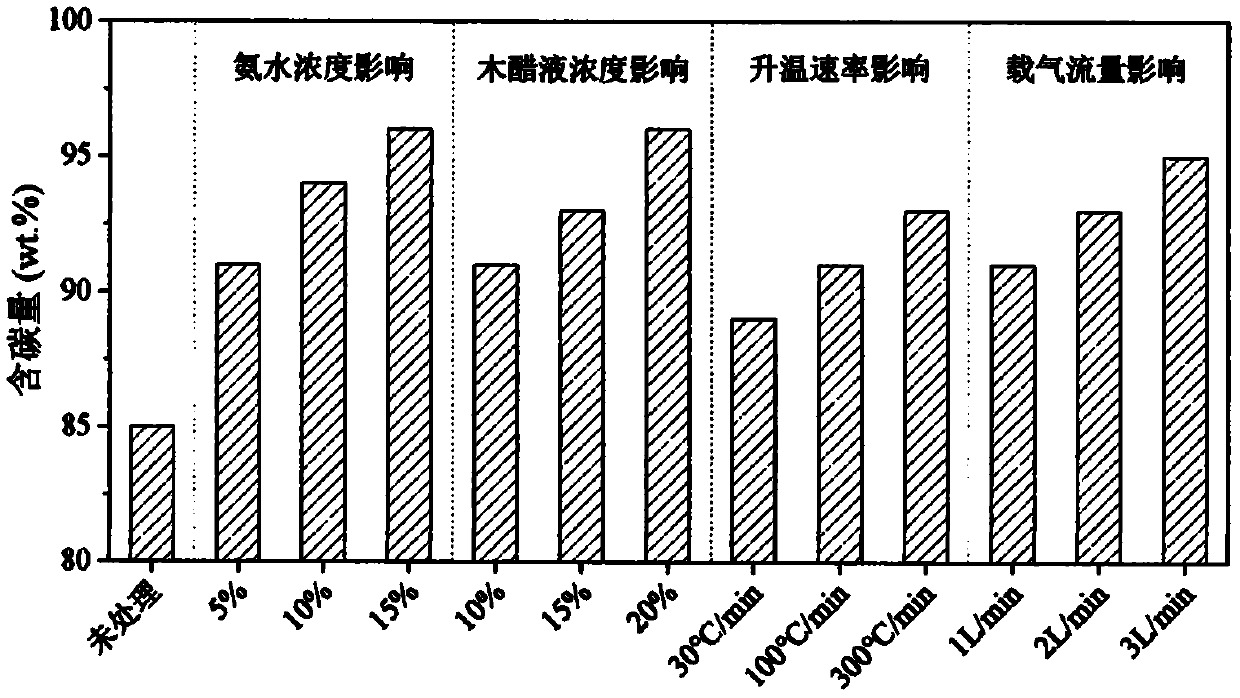

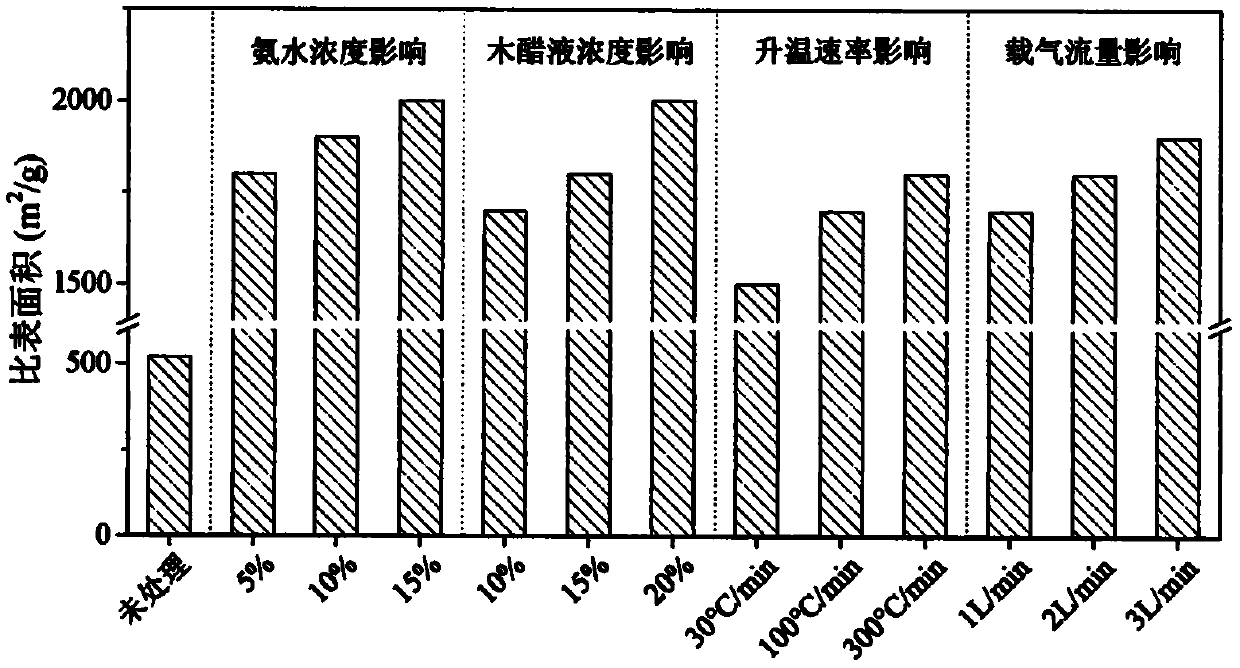

[0041] The embodiment of the present invention describes a method of using biomass to prepare nitrogen-doped carbon catalyst, and the method specifically includes the following steps:

[0042] S1: After pulverizing the bamboo waste to <120 mesh, fully mix it with KOH activator by dipping, the ratio of the three is 1:50, after dipping for 24 hours, evaporate the water in it under an argon atmosphere at 60°C, and get mixed samples;

[0043] S2: Put the mixed sample in step S1 into a fixed bed reactor for activation reaction under argon atmosphere, the heating rate is 100°C / min, the high carrier gas flow rate is 1L / min, the reaction temperature is 900°C, and the reaction time is For 2 hours, the biomass fully reacts with the alkaline activator to obtain activated carbon with high porosity and high content;

[0044] S3: Put the activated carbon obtained in step S2 into the ammonia solution, the concentration of ammonia water is 15%, shake and soak for 1 day, the ammonia water is ...

Embodiment 2

[0048] S1: After pulverizing the bamboo waste to <120 mesh, fully mix it with KOH activator by dipping, the ratio of the three is 1:50, after dipping for 24 hours, evaporate the water in it under an argon atmosphere at 60°C, and get mixed samples;

[0049] S2: Put the mixed sample in step S1 into a fixed bed reactor for activation reaction under argon atmosphere, the heating rate is 100°C / min, the high carrier gas flow rate is 1L / min, the reaction temperature is 900°C, and the reaction time is For 2 hours, the biomass fully reacts with the alkaline activator to obtain activated carbon with high porosity and high content;

[0050] S3: Put the activated carbon obtained in step S2 into the ammonia solution, the concentration of ammonia water is 10%, shake and soak for 1 day, the ammonia water fully reacts with the unreacted SiO in the activated carbon 2 reaction to obtain activated carbon after ammonia treatment;

[0051] S4: Immerse the activated charcoal obtained in step S3 i...

Embodiment 3

[0054] S1: After pulverizing the bamboo waste to <120 mesh, fully mix it with KOH activator by dipping, the ratio of the three is 1:50, after dipping for 24 hours, evaporate the water in it under an argon atmosphere at 60°C, and get mixed samples;

[0055] S2: Put the mixed sample in step S1 into a fixed bed reactor for activation reaction under argon atmosphere, the heating rate is 100°C / min, the high carrier gas flow rate is 1L / min, the reaction temperature is 900°C, and the reaction time is For 2 hours, the biomass fully reacts with the alkaline activator to obtain activated carbon with high porosity and high content;

[0056] S3: Put the activated carbon obtained in step S2 into the ammonia solution, the concentration of ammonia water is 5%, shake and soak for 1 day, the ammonia water is fully mixed with the unreacted SiO in the activated carbon 2 reaction to obtain activated carbon after ammonia treatment;

[0057] S4: Immerse the activated charcoal obtained in step S3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com