Method for preparing alkoxy compound by oxyalkylation

An alkoxy compound and alkoxylation technology, which is applied in the preparation of amino compounds from amines, the preparation of organic compounds, and the preparation of ethers from alkylene oxides. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0024] Add 200g of alcohol ether carboxylic acid into the flask, add 100g of water and 100g of isopropanol, stir and heat to 90°C, then add an equivalent mole of calcium oxide or magnesium oxide powder (calculated from the acid value of alcohol ether carboxylic acid) Gradually add it to the flask, and after fully reacting, remove the water and solvent by rectification to obtain the catalyst.

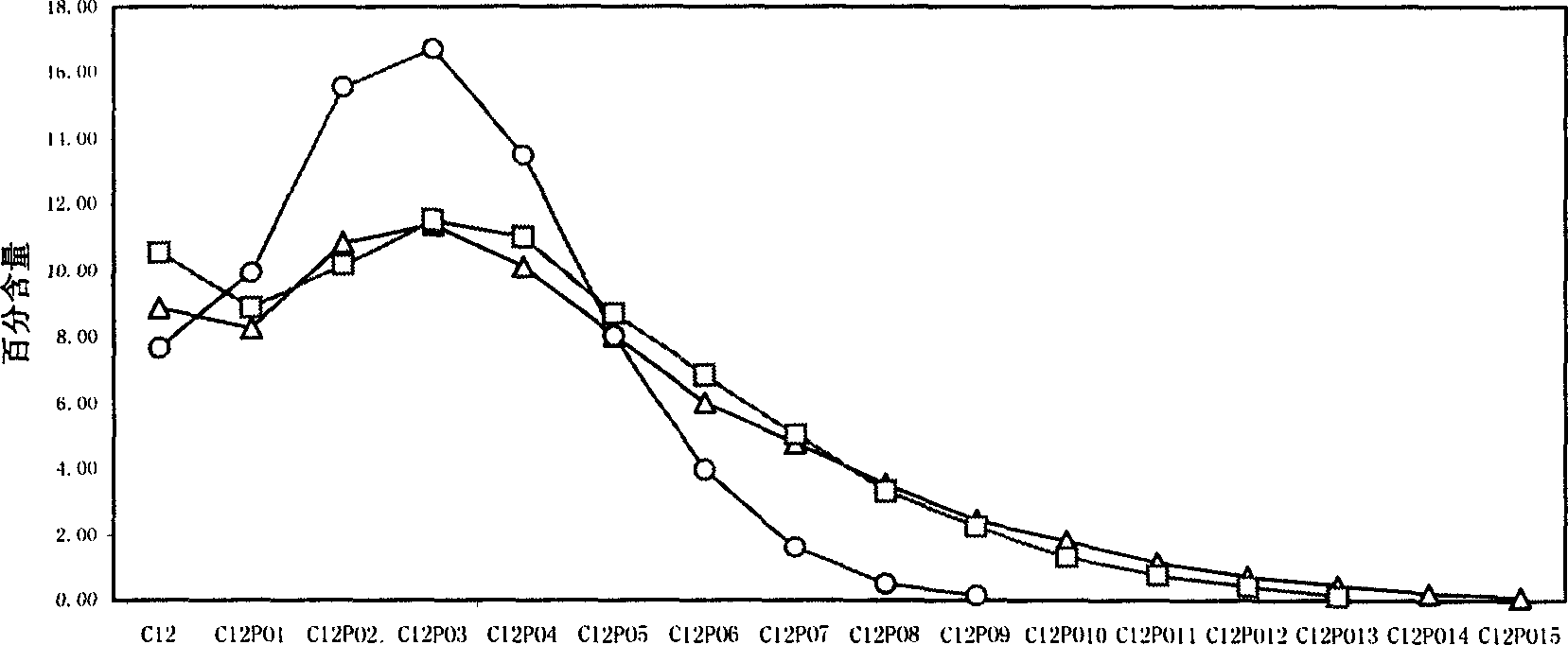

[0025] 600g C 12 ~C 14 Add mixed alcohol and 20g of catalyst into a 2-liter high-pressure reactor, replace with nitrogen to remove oxygen, raise the temperature to 100-120°C, vacuumize for 0.5-1 hour, then raise the temperature to 160°C, and pass 30g of propylene oxide to carry out Initiate the reaction. After initiating the reaction, continuously add a total amount of 380 g of propylene oxide (the equivalent required for the reaction) to the reactor, and keep the system pressure at 0.2 to 0.4 MPa during the addition. After the reaction is completed, it is aged for 20 minutes, cooled t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com